In the defense industry, plastic injection molding plays a major role in creating durable, high-performance components that meet stringent safety standards and operational requirements.

As the Plastics Injection Molding Market grows, with an estimated size of 157.13 million tons in 2025, expected to reach 193.76 million tons by 2030, the demand for precision-engineered plastic parts in defense applications continues to rise.

This blog examines the applications of the defense industry plastic injection molding, as well as its advantages and potential developments.

Key Takeaways

- Plastic injection molding provides precision, durability, and high-performance components for defense applications.

- Common materials like Nylon, ABS, and Polycarbonate ensure strength and resistance to harsh conditions.

- The process supports high-volume production of lightweight yet strong parts for military vehicles, communication devices, and protective gear.

- Injection molding improves the reliability and longevity of important defense components under extreme conditions.

- The method is cost-effective, offering consistent quality and reduced manufacturing time for defense manufacturers.

What is Plastic Injection Molding in the Defense Industry?

Plastic injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure to form specific parts or components. In the defense industry, plastic injection molding is used to produce components that are lightweight, strong, and resistant to harsh conditions, such as extreme temperatures, moisture, and chemicals.

The defense industry plastic injection molding process is often used for producing high-precision parts that require tight tolerances and can withstand demanding conditions. Parts made using this method are used in various military equipment and defense applications, from communication devices to protective gear.

Building on the importance of precision and durability in defense manufacturing, Jairaj Group provides advanced plastic injection molding, rotational molding, and extrusion molding solutions that meet the highest standards. Using Polypropylene (PPCP), ABS, and Polyethylene (PE), we produce components like dashboard panels, cable routing channels, and HVAC ducts for military applications.

This leads us to why plastic injection molding is essential for military-grade component manufacturers.

Why Plastic Injection Molding is Essential for Military-Grade Component Manufacturers

In the defense industry, where durability is non-negotiable, plastic injection molding provides the strength and versatility needed for a wide range of applications. Here’s how it adds value to military-grade parts.

- Durability and Reliability: Components made using injection molding are highly durable and can withstand extreme conditions, making them ideal for defense applications where reliability is paramount.

- Precision and Accuracy: Plastic injection molding allows for the production of parts with tight tolerances, ensuring high-quality, consistent components that meet the required standards.

- Cost-Effectiveness: Once a mold is created, producing large quantities of components becomes cost-effective, making it a suitable option for defense applications where high volumes of parts are needed.

- Material Versatility: Plastic injection molding offers a wide range of material choices, from engineering-grade thermoplastics to high-performance polymers that meet the specific needs of military applications.

- Lightweight Components: Plastic injection-molded parts are lighter than metal counterparts, making them ideal for reducing the weight of military equipment without compromising strength or durability.

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

Understanding the top applications of injection-molded plastics in defense manufacturing can further highlight their value.

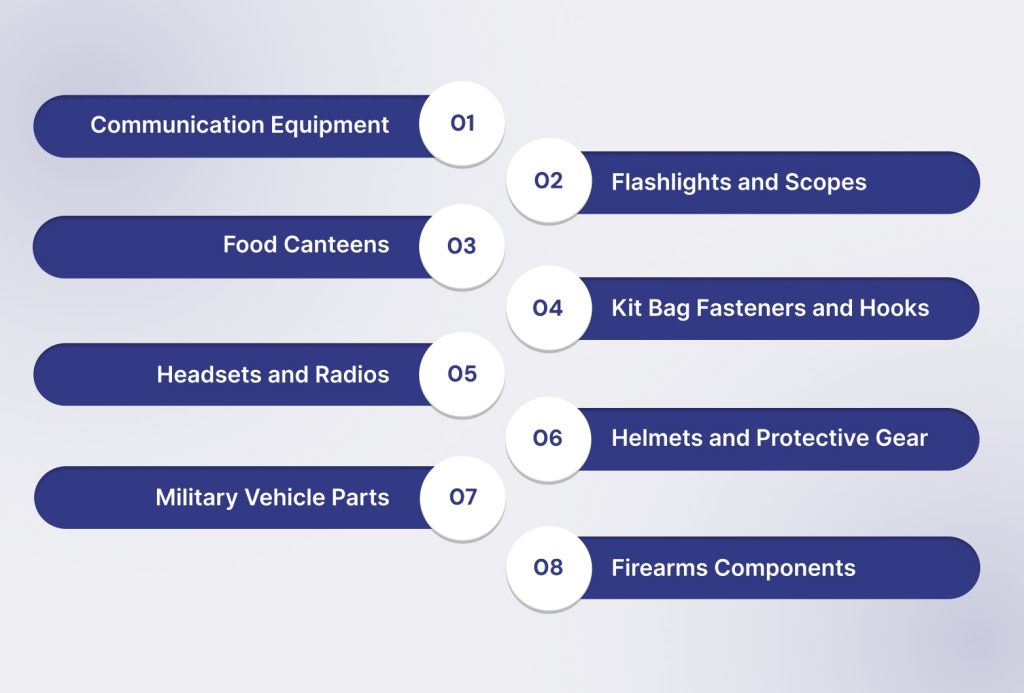

8 Applications of Injection-Molded Plastics in Defense Manufacturing

Injection-molded plastics are indispensable in manufacturing military equipment, from communication devices to protective gear, ensuring high performance and durability. Below are key applications that enhance military operations.

1. Communication Equipment

Plastic components are used in communication devices such as radios, satellites, and mobile units. Injection-molded parts ensure these devices are lightweight, durable, and resistant to impact.

2. Flashlights and Scopes

Military-grade flashlights and optical scopes require precision components that can withstand rough conditions. Plastic injection molding is used to produce casings, lenses, and mounting parts for these devices.

3. Food Canteens and Drink Containers

Lightweight and durable plastic materials are used to make military-grade food canteens and drink containers that can endure harsh environments and are easy to carry in the field.

4. Kit Bag Fasteners and Hooks

Durable, high-performance plastic parts are used for bag fasteners, clips, and hooks that are an essential part of military kit bags and gear.

5. Headsets and Radios

Plastic injection molding is used for producing the casings and connectors in headsets and radios used by military personnel, ensuring the equipment is both durable and lightweight.

6. Helmets and Protective Gear

Plastic parts are integral to the manufacturing of military helmets and body armor. Injection-molded components provide the necessary protection and strength while minimizing weight.

7. Military Vehicle Parts

Plastic components are used in various parts of military vehicles, such as interior panels, dashboard components, and lightweight armor plating, offering strength without adding excess weight.

8. Firearms Components

Injection-molded plastics are used in the production of firearm parts, including grips, stocks, and trigger guards, providing lightweight strength and durability.

Also Read: Injection Moulding Plastic Components Manufacturer and Exporters in India

Next, let’s explore the plastic materials that are commonly used in defense industry injection molding.

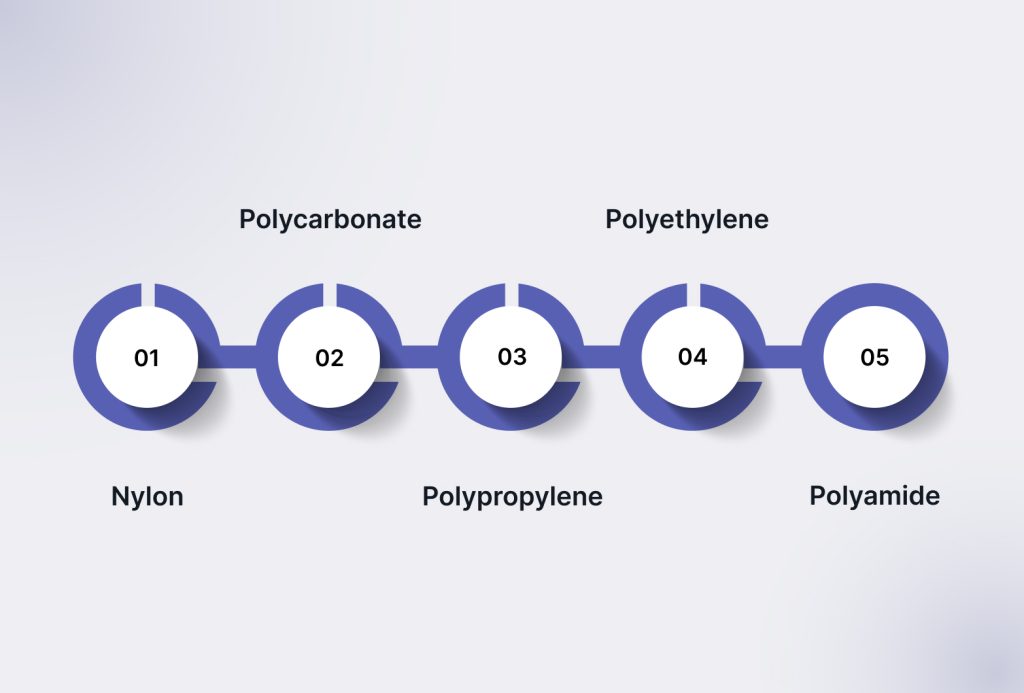

Plastic Materials for Defense Industry Injection Molding

The defense industry requires materials that offer strength, durability, and resistance to environmental factors. Some commonly used materials for plastic injection molding in defense applications include:

- Nylon: Known for its high strength, flexibility, and resistance to wear, nylon is used in a variety of defense components, including gears and fasteners.

- Polycarbonate: Offering excellent impact resistance and clarity, polycarbonate is often used for optical components and protective covers in military equipment.

- Polypropylene (PP): With excellent chemical resistance and lightweight properties, polypropylene is commonly used in military-grade containers, fuel systems, and medical equipment.

- Polyethylene (PE): Used in applications requiring toughness and resistance to chemical exposure, polyethylene is widely used for various military parts, including protective barriers and containers.

- Polyamide (PA): Known for its high strength, impact resistance, and wear resistance, polyamide is used in military equipment like gears, bearings, and components exposed to harsh environments.

Also Read: Top Plastic Manufacturers in 2025

Now, let’s discuss the manufacturing practices that ensure precision and quality in military component production.

Plastic Injection Mold Manufacturing Practices for Military Component Production

Manufacturing high-quality plastic parts for defense applications requires precision and adherence to strict standards. The following practices are essential for producing plastic components used in military systems:

1. Custom Mold Design

Precision mold design ensures that each part meets the specifications for size, shape, and performance. The use of advanced design tools like CAD (computer-aided design) software allows manufacturers to create detailed, accurate molds for complex parts.

2. Material Selection

The selection of the right material is important for ensuring the performance and durability of plastic components. Manufacturers must choose materials that can withstand extreme temperatures, pressure, and environmental conditions typically encountered in defense applications.

3. Quality Control and Testing

Each component must undergo rigorous quality checks and testing, including dimensional inspections, stress tests, and environmental resistance evaluations. These tests ensure the parts meet military standards for performance and safety.

4. Batch Production

Once the mold is created, large quantities of parts can be produced efficiently. With injection molding, hundreds or thousands of parts can be produced with reliable quality.

5. Post-Processing and Finishing

After molding, parts often undergo finishing processes like painting, coating, and assembly to meet the specific requirements for each defense application.

Also Read: 5 Best Plastics for Durable Outdoor Use

Looking forward, future trends in the defense industry plastic injection molding should be closely observed for continued innovation.

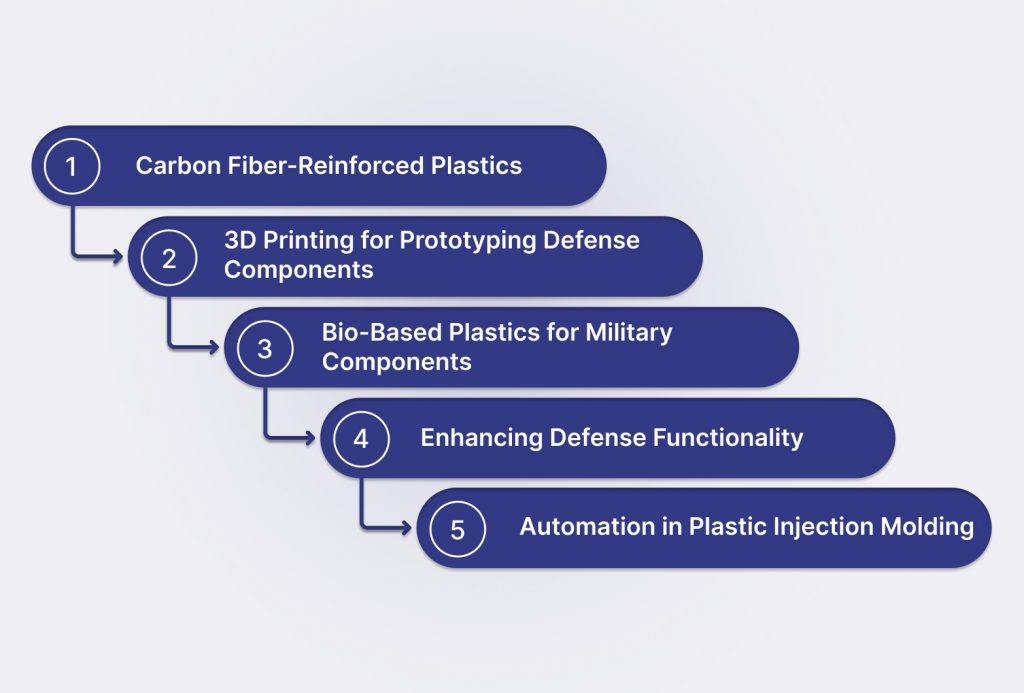

5 Future Trends in the Defense Industry Plastic Injection Molding that Manufacturers Must Look Out For

Advanced plastic components are becoming more and more in demand as the defense sector develops. Here are some key trends shaping the future of plastic injection molding in the defense industry:

1. Carbon Fiber-Reinforced Plastics

The development of carbon fiber-reinforced plastics is revolutionizing defense manufacturing by offering lightweight, high-strength materials for components like military vehicle parts and protective gear.

2. 3D Printing for Prototyping Defense Components

3D printing enables the defense sector to create custom components rapidly, improving efficiency and precision in parts like military vehicle components and communication systems.

3. Bio-Based Plastics for Military Components

There’s a growing emphasis on using bio-based plastics and recyclable materials in defense manufacturing, reducing environmental impact without compromising the performance of components like UAV parts.

4. Enhancing Defense Functionality

Smart plastics integrated with sensors can monitor conditions or detect environmental changes, improving the performance and safety of tactical equipment and communication devices.

5. Automation in Plastic Injection Molding

Advancements in manufacturing automation allow for more precise and efficient production of military components, such as armor-piercing shells and military vehicle parts, reducing production time and cost.

Also Read: Top 8 Heat-Resistant Plastics Used Across Industries

Now, let’s understand how partnering with experts in precision-engineered plastics can enhance the reliability of your defense components.

Partner with Experts in Precision-Engineered Plastics for Reliable Defense Components

In defense applications, precision, durability, and performance are non-negotiable. Jairaj Group understands that modern defense platforms require more than just strength; they demand lightweight, adaptable materials designed to withstand the toughest conditions.

With over 35 years of expertise, we specialize in producing high-performance plastic components that meet the changing needs of armoured vehicles, tactical transport, and ground support systems. From injection-molded to blow-molded and roto-molded parts, we use defense-grade polymers to ensure reliability, performance, and reduced weight across military applications.

Here’s why Jairaj Group is your trusted partner for high-performance plastic injection molding in defense applications:

- Plastic Injection Molding: High-performance parts such as braking system components and precision components from advanced polymers ensure robust defense solutions.

- High-Strength Materials: We use Nylon, PBT Arnite, and Polycarbonate for durable and impact-resistant components such as fuel connectors, engine assemblies, and protective caps. Our materials offer superior weather and UV resistance, ensuring long-term durability and performance in extreme environments.

- Manufacturing Technologies: From plastic blow molding for hand grips to extrusion molding for heavy vehicle components, we deliver precision-engineered solutions tailored for defense applications.

- Expertise and Certification: Our ISO 9000, IATF, and CE certifications demonstrate our commitment to quality, ensuring compliance with global standards in defense manufacturing.

- Comprehensive Production: With advanced machining and turning capabilities, we produce high-precision components that meet the demanding requirements of military and defense sectors.

- High-Performance Components for Armored Vehicles: Armoured Personnel Carriers (APCs), Infantry Fighting Vehicles (IFVs), Tactical Logistics Trucks, and Combat Engineering Vehicles benefit from our lightweight, high-performance components that improve system integration and vehicle mobility.

- Modular Housings for Military Systems: We manufacture modular housings and system enclosures, including battery enclosures and access covers, designed to protect military systems while ensuring ease of maintenance in demanding field conditions.

- Lightweight Integrated Vehicle Components: Dashboard panels and HVAC ducts contribute to improved payload capacity, thermal insulation, and NVH performance in defense vehicles.

With our state-of-the-art manufacturing facilities across Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand, we deliver military-grade plastic components that ensure top-tier performance and durability, optimized for tactical and off-road platforms in the defense sector.

Conclusion

Defense industry plastic injection molding process provides key benefits such as durability, precision, and versatility, which are ideal for producing components like communication equipment, helmets, and vehicle parts in military systems. As the industry grows, advanced materials, 3D printing, and sustainability efforts will further shape the future of plastic molding in defense.

For precision-engineered components that meet the rigorous demands of the defense industry, Jairaj Group offers top-tier injection-molded plastics. With materials like Nylon 6/66, PBT Arnite, and Polycarbonate, our advanced molding technologies ensure components that are both lightweight and durable for military vehicles, communication systems, and protective gear.

Get in touch with Jairaj Group for reliable plastic solutions that deliver performance, strength, and compliance with the toughest defense standards.

FAQs

1. What makes plastic injection molding ideal for defense applications?

Plastic injection molding offers high precision, durability, and lightweight components, making it perfect for producing defense parts that withstand extreme conditions and demanding use.

2. What types of plastic are used in defense injection molding?

Materials like Nylon 6/66, ABS, and Polycarbonate are used due to their strength, durability, and resistance to harsh environments in defense applications.

3. How does plastic injection molding improve defense component performance?

Plastic injection molding ensures tight tolerances, high strength, and consistent quality, which enhances the reliability and longevity of defense components like protective gear and vehicle parts.

4. Can plastic injection-molded parts be used in military vehicles?

Yes, plastic injection-molded parts, like vehicle components, cable ducts, and dashboard panels, are used in military vehicles to reduce weight and enhance durability.

5. What benefits does plastic injection molding offer over alternative defense manufacturing techniques?

Injection molding provides high-volume, cost-effective production of complex, precision parts with consistent quality, ensuring reliability in mission-critical defense applications.

6. How does plastic injection molding ensure safety in defense equipment?

Plastic injection molding creates strong, lightweight, and impact-resistant parts for defense equipment like military vehicles and protective gear, ensuring durability and reliability under extreme conditions.