In aerospace, every component must meet the highest standards of precision. One method driving innovation in component manufacturing is aerospace thermoform tooling. This process involves heating a plastic sheet and shaping it into complex forms using molds, producing lightweight, cost-effective solutions for various aerospace applications.

The global thermoformed plastic market, crucial to both aerospace and medical manufacturing, is projected to reach USD 20.66 billion (₹1,70,000 crores) by 2030. This growth reflects the increasing demand for thermoforming’s ability to create intricate parts at scale, particularly in commercial and military aviation.

This blog will explore the various applications, methods, materials, and benefits of thermoforming solutions in the aerospace industry.

Key Takeaways

- Thermoforming offers a cost-effective solution for lightweight, durable aerospace components like seatbacks and thermal shields.

- Materials such as Polycarbonate and PEI ensure strength and performance in demanding aerospace environments.

- Thermoforming technologies reduce lead times, making them ideal for producing complex aerospace parts efficiently.

- Impact resistance and heat tolerance are essential properties of aerospace thermoformed components for safety and performance.

- Precision molding ensures parts meet stringent industry standards, enhancing the longevity and reliability of aerospace systems.

What is Thermoforming in Aerospace Manufacturing?

Thermoforming is a manufacturing process where a thermoplastic sheet is heated to a pliable forming temperature, then molded into a specific shape. In aerospace, thermoforming is used to produce various components such as aircraft interiors, protective covers, and structural parts.

Thermoforming in aerospace is a cost-effective manufacturing solution and also helps in reducing the overall weight of components. Lightweight components are crucial in aerospace design, as they improve fuel efficiency and reduce operational costs. Additionally, thermoforming offers precise tolerances, ensuring that the final product fits seamlessly within larger aerospace systems.

Benefits of Thermoforming For Aerospace Components Manufacturers

Thermoforming provides a wide range of benefits to the aerospace industry, making it an attractive choice for many applications. Here are the key advantages:

- Cost-Effectiveness: Thermoforming is an affordable manufacturing method that reduces production costs compared to more traditional techniques like injection molding.

- Lightweight Components: Thermoforming allows for the creation of parts that are lightweight, which is crucial for improving fuel efficiency in commercial and military aircraft.

- Customization and Precision: The flexibility of thermoforming enables the production of highly customized components, meeting the specific needs of aerospace manufacturers.

- Durability and Strength: Thermoformed plastics offer high durability and impact resistance, which are essential for components exposed to harsh environments and extreme temperatures.

- Faster Turnaround Time: Thermoforming can be faster than other manufacturing methods, allowing for quicker production cycles and faster delivery of components to aerospace manufacturers.

For aerospace manufacturers facing challenges in producing thermal insulation panels and satellite components, Jairaj Group offers precision thermoforming with Polyetherimide (PEI) and Polycarbonate. Our advanced injection molding techniques ensure lightweight, durable parts that meet stringent aerospace standards for temperature and stress resilience.

Also Read: Top Plastic Manufacturers in 2025

Moving forward, let’s explore the most common components produced using this technique.

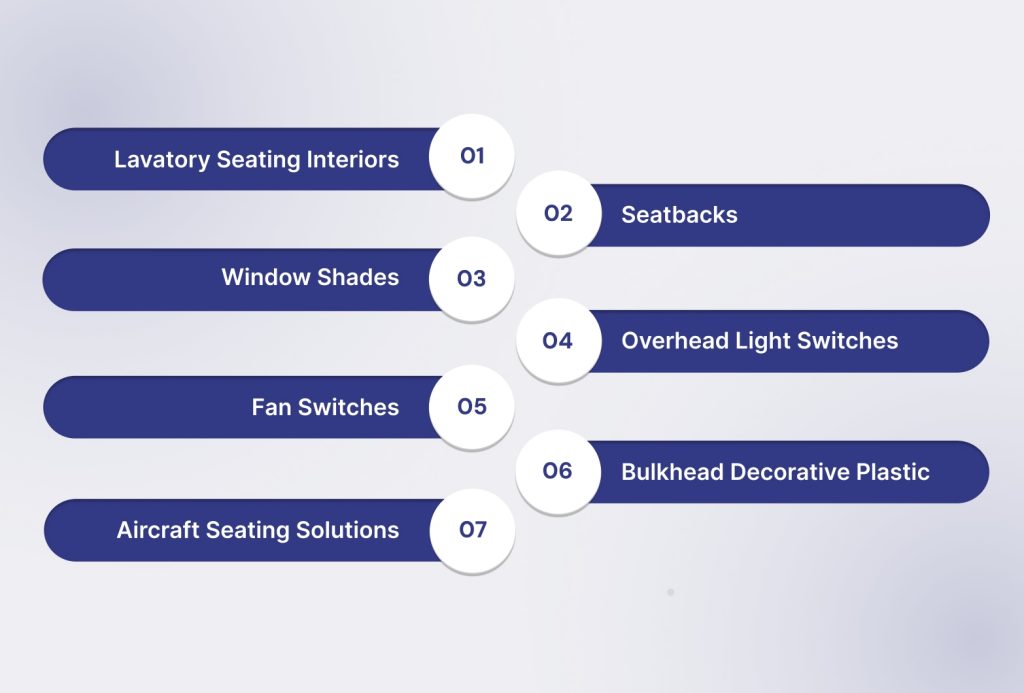

Common Components in Aerospace Thermoform Manufacturing

Aerospace manufacturers use thermoforming to create a variety of components, particularly for aircraft interiors and exteriors. Here are some key applications of thermoformed components in aerospace:

1. Seating and Cabin Interiors for Airplane Lavatories

Thermoformed plastics are used to create lightweight, durable panels for airplane lavatories and partitions. These parts are designed to withstand high traffic and offer superior resistance to wear and tear in tight spaces.

2. Seatbacks

Thermoforming provides an ideal solution for producing ergonomic seatbacks that are both impact-resistant and comfortable, ensuring passenger safety and comfort while meeting strict aerospace standards.

3. Window Shades

Thermoformed plastics for window shades offer lightweight, durable solutions that are easy to install, resistant to UV damage, and designed to perform well under varying environmental conditions.

4. Overhead Light Switches

The precise forming capabilities of thermoforming allow manufacturers to create overhead light switches with long-lasting durability and reliable performance, even in high-traffic areas like airplane cabins.

5. Fan Switches

Thermoformed plastics are ideal for producing fan switches due to their heat resistance and impact strength, ensuring that they remain operational even under high-temperature and high-usage conditions.

6. Decorative Plastic in the Bulkhead

Thermoformed plastic components are used in bulkheads to offer a streamlined, modern aesthetic without compromising on strength. These parts provide both aesthetic value and structural support in aircraft interiors.

7. Commercial and Private Aircraft Seating

Thermoforming is widely used for producing seating components in both commercial and private aircraft, ensuring they meet safety standards while providing comfort and durability for long-term use.

Also Read: Vehicle Handbrake Lever Manufacturer and Exporters – Quality, Precision & Performance

Now, let’s look into the popular methods used to create these components.

Popular Thermoforming Methods for Aerospace Components

Several thermoforming methods are employed in the aerospace industry, each with its unique benefits and applications. These methods allow manufacturers to produce complex, lightweight parts quickly and efficiently. Below are some of the most common thermoforming techniques used in aerospace manufacturing:

- Blow Molding: Blow molding is used to create hollow plastic parts, such as fuel tanks and air ducts, which require strong, impact-resistant materials.

- Pressure Forming: This technique is ideal for producing components with high precision, where the plastic sheet is pressed against the mold using vacuum or air pressure.

- Mechanical Forming: Mechanical forming involves using mechanical forces to shape the plastic into the desired form, ensuring strong and uniform components.

- Drape Forming: In drape forming, the heated plastic sheet is manually draped over the mold, which is ideal for creating parts with smooth surfaces and fine details.

- Matched-die Thermoforming: This method uses two molds to shape the plastic, offering high precision and is typically used for creating complex aerospace parts like brackets and supports.

- Billow Forming: Billow forming uses a large air bubble to expand the plastic sheet over a mold, suitable for producing large, lightweight components such as fairings and panels.

- Twin Sheet Forming: Twin sheet forming involves using two plastic sheets that are heated and then pressed together to create strong, hollow parts for applications like aircraft interior panels.

Also Read: What is Plastic Welding?

Next, we’ll look at the types of equipment used in aerospace thermoforming.

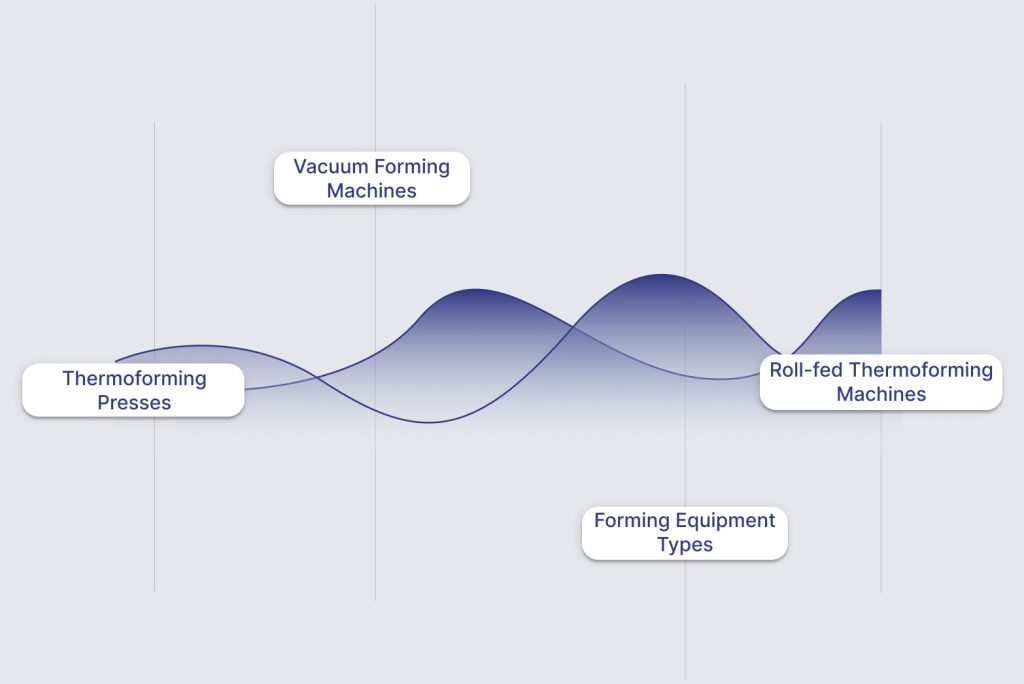

4 Types of Thermoforming Equipment for Aerospace Applications

Thermoforming equipment plays a critical role in ensuring the precise shaping of aerospace components. The type of equipment used depends on the complexity, size, and material requirements of the part. Common types of thermoforming equipment include:

- Thermoforming Presses: These machines apply pressure to a heated plastic sheet and a mold, creating a specific shape or form. They are ideal for producing large or complex components.

- Vacuum Forming Machines: Vacuum forming machines use vacuum pressure to pull the plastic sheet into the mold, creating parts that are both lightweight and durable.

- Roll-fed Thermoforming Machines: These machines feed continuous sheets of plastic into the thermoforming machine, suitable for high-volume production of parts like window shades and paneling.

- Manual and Semi-Automatic Forming Equipment: Used for low to medium-volume production, these machines offer greater flexibility and precision in creating custom aerospace parts.

Also Read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

Understanding the process behind these machines is crucial, so let’s break it down further.

Process of Thermoform Manufacturing in Aerospace

The process of thermoform manufacturing in aerospace typically involves several stages, from material preparation to the final production of the part. Here’s a brief overview of the steps involved:

- Material Selection: The first step is choosing the right plastic material, such as Polycarbonate, Polyphenylene Sulfide (PPS), or Polyetherimide (PEI), based on the specific requirements of the component.

- Heating the Plastic Sheet: The selected plastic sheet is heated to a temperature where it becomes pliable, making it easier to shape.

- Molding: The heated plastic is then pressed into a mold or shaped using vacuum or air pressure to form the desired component.

- Cooling and Trimming: After forming, the plastic part is cooled to solidify its shape. Any excess material is then trimmed off, and the part is prepared for finishing.

- Quality Control: The final part undergoes stringent quality control tests to ensure it meets the required specifications for strength, durability, and safety.

Now that we understand the process, let’s explore the main applications of thermoformed components in aerospace.

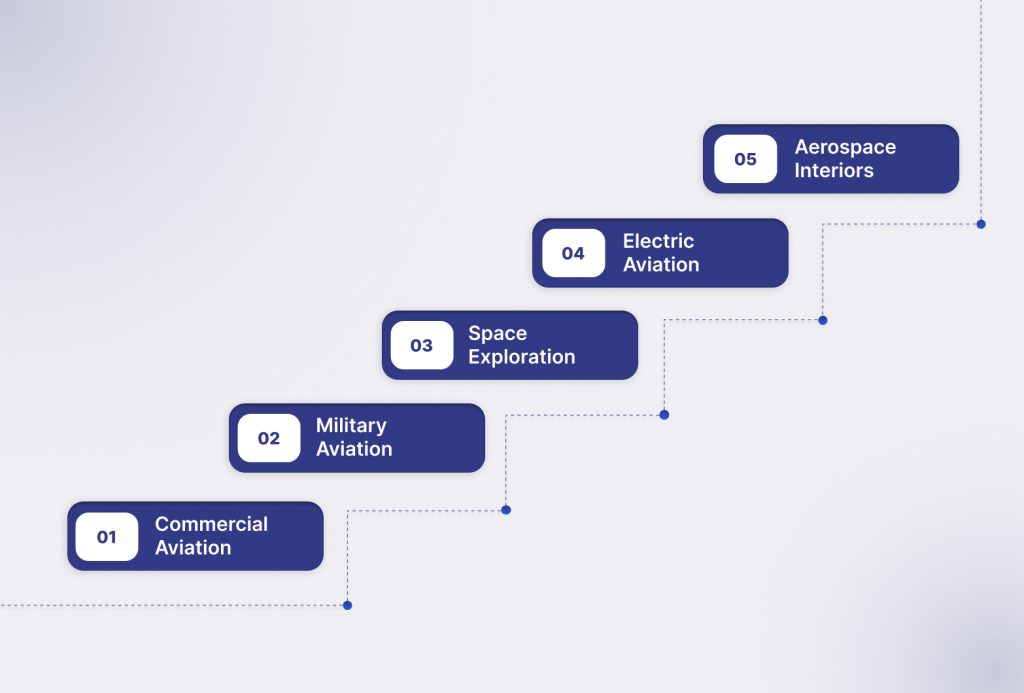

Main Applications of Thermoform Components in Aerospace Industries

Thermoforming is widely used in various sectors within the aerospace industry. Its ability to produce lightweight, durable, and cost-effective components makes it ideal for a range of applications:

1. Commercial Aviation

Thermoforming is used to produce interior panels, seatbacks, and overhead bins that are both lightweight and durable. These parts meet aesthetic standards and ensure structural integrity and passenger safety during flight.

2. Military Aviation

In military applications, thermoformed components such as control panels, radar covers, and housings provide high impact resistance and heat tolerance, which are critical in combat and field conditions. These parts ensure that military aircraft remain functional and reliable under extreme environments.

3. Space Exploration

Thermoforming is essential for producing lightweight yet durable components like satellite panels, thermal shields, and interior components for spacecraft. Thermoformed plastics help reduce weight while maintaining the strength required to withstand the harsh conditions of space.

4. Electric Aviation

As electric aviation grows, thermoforming is used for battery enclosures, electrical insulation, and aircraft structural components. These parts benefit from thermoformed lightweight materials that enhance energy efficiency and reduce weight, which are essential for maximizing aircraft performance.

5. Aerospace Interiors

Thermoformed plastics are used to create cabin interiors such as walls, ceilings, and bulkheads. These components offer high durability, aesthetic flexibility, and fire resistance, making them ideal for aerospace environments where safety and comfort are paramount.

Also Read: Automotive Interior & Exterior Plastic Parts Manufacturing: Trends and Innovations in 2025

To gain a better understanding, we need to look at the types of materials used in aerospace thermoforming.

What Plastic Materials Are Used for Thermoforming in Aerospace?

Several plastic materials are commonly used in the aerospace industry for thermoforming, each offering distinct advantages for specific applications. Some of the most popular materials include:

- Polyetherimide (PEI): Known for its excellent mechanical properties and heat resistance, PEI is often used for aerospace components like electrical enclosures and thermal protection.

- Polycarbonate (PC): Polycarbonate is a tough, impact-resistant material ideal for aircraft windows and safety shields.

- ABS (Acrylonitrile Butadiene Styrene): ABS is a versatile material used in parts like aircraft interiors and housing for electronics due to its strength and processability.

- Polyphenylene Sulfide (PPS): PPS offers high thermal stability and chemical resistance, making it ideal for parts exposed to extreme environments.

- High-Density Polyethylene (HDPE): HDPE is used for lightweight components such as cabin panels and protective covers that require resistance to wear and impact.

To compare these materials, let’s examine how thermoforming stands against thermosetting plastics in aerospace manufacturing.

Thermoforming vs. Thermosetting Plastics in Aerospace Manufacturing

Although thermoforming and thermosetting plastics are both frequently utilized in the aerospace industry, they differ significantly. Here’s a quick comparison of the major differences:

| Property | Thermoforming | Thermosetting |

| Reshaping | Can be reshaped multiple times after heating. | Cannot be reshaped after curing, retains permanent shape. |

| Manufacturing Process | Heated plastic sheets molded into desired shape. | Undergoes a chemical change during molding to form a rigid shape. |

| Use Case | Ideal for flexible, reusable parts like interior panels. | Best for high-strength, heat-resistant parts like engine components. |

While thermoforming offers flexibility and ease of molding, thermosetting plastics provide enhanced rigidity under heat. Resolving challenges with thermoforming in aerospace manufacturing will ensure these materials meet stringent standards.

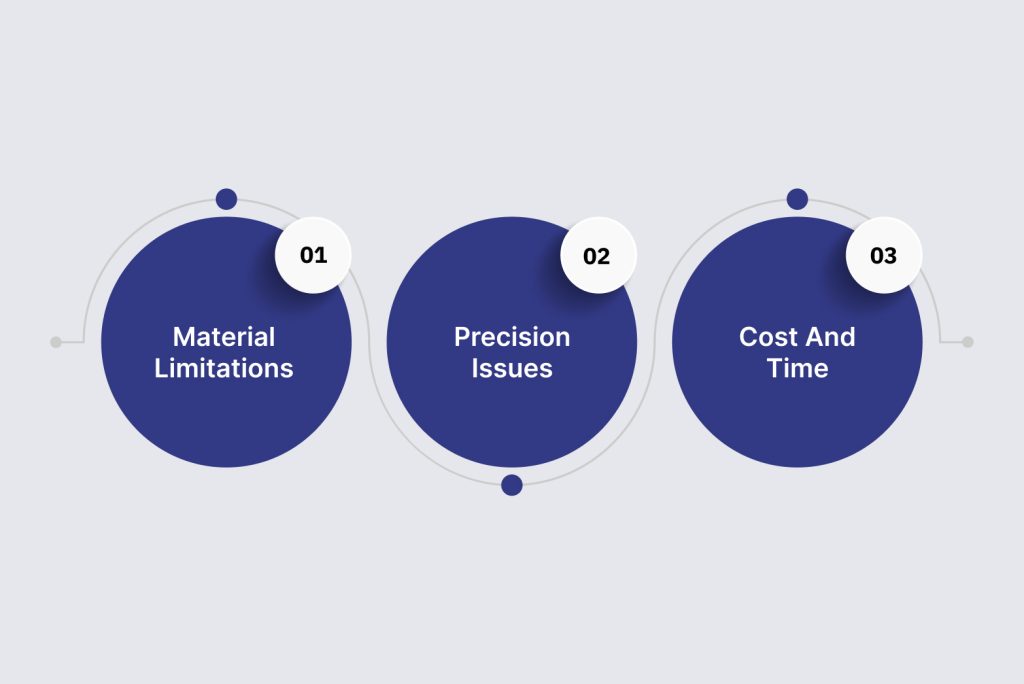

Overcoming Thermoforming Manufacturing Challenges in Aerospace

Thermoforming in aerospace offers numerous benefits, but it also comes with its unique set of challenges. The following are some of the key challenges aerospace component manufacturers face:

1. Material Limitations

Not all plastic materials are suitable for thermoforming in aerospace, which requires a careful selection to ensure they meet the specific requirements for strength and durability.

Solution: Using specialized aerospace-grade materials like Polycarbonate and Polyetherimide (PEI) ensures the required performance under extreme conditions.

2. Precision Issues

Achieving tight tolerances on complex parts can be difficult, especially when parts are small and intricate, requiring precise shaping.

Solution: Advanced molding technologies such as matched-die thermoforming and pressure forming can improve precision and ensure the necessary tolerances for critical aerospace components.

3. Cost and Time

Complex aerospace components may require longer production cycles, additional finishing steps, and strict quality control to ensure high-performance standards.

Solution: Optimizing production workflows and using automated thermoforming processes can reduce production time and enhance cost-efficiency while maintaining component quality.

Also Read: Overmolding Guide: Process, Design, and Importance

As we tackle these challenges, let’s transition to a different, but equally critical sector: medical-grade plastic materials.

Partner with Expert Aerospace Thermoforming Tooling Providers for Optimal Performance

When it comes to high-performance components in aerospace, Jairaj Group leads the way in thermoforming solutions. With over 35 years of experience in manufacturing precision plastic components, we specialize in producing durable and reliable parts for industries like automotive, defense, and aerospace. Our advanced manufacturing facilities in Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand ensure top-quality, high-performance products designed to meet stringent aerospace standards.

Here’s why you should choose Jairaj Group for aerospace thermoforming solutions:

- Advanced Thermoforming Technologies: We employ cutting-edge techniques like plastic injection molding and rotational molding, producing high-quality aerospace components such as Roto Moulding Components, Brake Pedals, and Precision Components from Advance Polymers.

- Precision Materials: Our use of high-performance materials like Polycarbonate, PBT Arnite, and Poly Acetal (POM) ensures that components like brackets, tube guides, and engine assemblies meet the tough demands of the aerospace industry.

- Lightweight & Durable Parts: We specialize in creating lightweight components for aircraft interiors and aerospace applications, ensuring minimal weight without sacrificing strength, durability, or performance, such as Interior & Exterior Accessories and Mobility Plastic Base Seating Solutions.

- Customization for Aerospace Needs: Be it for aircraft seating solutions, military-grade components, or electronic enclosures, we offer tailored solutions to fit your unique specifications and requirements.

- ISO-Certified Quality: All our products are made under ISO 9000, ISO 14000, and IATF certifications, ensuring global standards of quality, environmental compliance, and performance reliability.

Partner with Jairaj Group to access the highest quality thermoforming solutions for aerospace components, offering strength, durability, and precision for critical applications.

Conclusion

By selecting the right materials and advanced thermoforming techniques, aerospace thermoform tooling manufacturers can enhance the durability and strength of components like cockpit panels, engine enclosures, and satellite housing under extreme conditions such as high-altitude pressure and fluctuating temperatures.

For high-performance aerospace components, Jairaj Group offers precision-engineered thermoforming solutions. With materials like Polycarbonate and PBT Arnite, we manufacture durable components such as aircraft seatbacks and interior panels. Our state-of-the-art injection molding and rotational molding technologies ensure that every part meets the highest industry standards for strength and reliability.

Get in touch with Jairaj Group to meet the demands of the aerospace industry and stay ahead in performance and innovation.

FAQs

1. What are the key benefits of thermoforming in aerospace?

Thermoforming provides lightweight, durable components with high precision, essential for producing parts like seating, panels, and protective components for aerospace applications.

2. How does thermoforming impact aerospace component performance?

Thermoforming ensures strength and durability in components while reducing weight, improving fuel efficiency and reducing costs for aerospace manufacturing, making it ideal for critical applications.

3. What types of materials are used in aerospace thermoforming?

Materials like Polycarbonate, PBT Arnite, and Polyetherimide (PEI) offer the necessary strength, impact resistance, and heat tolerance required for aerospace applications.

4. How does thermoforming improve the manufacturing process in aerospace?

Thermoforming streamlines production by enabling fast, cost-effective creation of complex parts, reducing lead times and providing precision that meets aerospace industry standards.

5. What aerospace components are commonly made using thermoforming?

Common thermoformed aerospace components include interior panels, seatbacks, thermal shields, and satellite housings, all requiring precision, durability, and resistance to extreme conditions.

6. How does thermoforming compare to other manufacturing methods in aerospace?

Thermoforming offers faster production times and lower costs than traditional methods, while still providing high-quality, lightweight, and durable components for aerospace applications.