Rajiv K Chawla has been the

driving force behind Jairaj Group's transformation from a single manufacturing unit in Faridabad

to a nationwide network of six advanced facilities. Under his leadership since 1985, the company

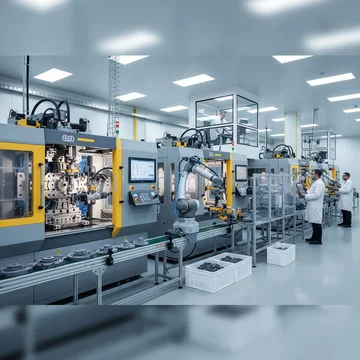

has pioneered precision plastic injection molding across critical industries—automotive,

aerospace, medical devices, and industrial engineering. His vision of "Straight Answers, Solid

Solutions" has shaped a culture of engineering excellence, operational transparency, and

customer-centric innovation. Rajiv has steered the company through strategic expansions

including the 2007 Rudrapur facility launch, the 2011 acquisition of Unique Mouldings, and the

establishment of state-of-the-art plants in Aurangabad, Manesar, Sanand, and Sector 59 Faridabad

between 2016-2020. His commitment to technological advancement is evident in Jairaj's adoption

of PLC-controlled machinery, in-house tool room capabilities, and comprehensive R&D centers.

Beyond growth metrics, Rajiv has cultivated lasting partnerships with industry leaders like

Endurance Technologies, Gabriel India Limited, and Tenneco Automotive—earning multiple supplier

excellence awards. His leadership philosophy centers on discovery, innovation, impact, and

integrity—values that have earned Jairaj recognition in Forbes India's DGEMS 2024 and Industry

Outlook Magazine's Top 10 list.