As Chairman of Jairaj Group,

Rajiv K Chawla has been instrumental in transforming a single manufacturing unit established in

1985 into a nationwide network of advanced polymer manufacturing facilities. Under his

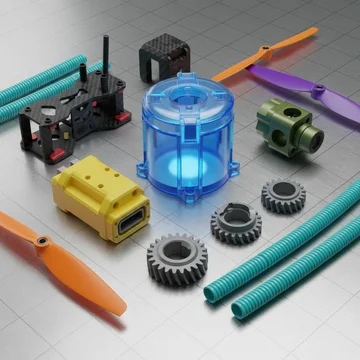

leadership, Jairaj Group has expanded from one plant in Faridabad to six strategic locations

across India, serving automotive, aerospace, agricultural, and emerging UAV sectors. His vision

has guided the company through critical milestones including technology modernization with

PLC-controlled machinery, acquisition and integration of Unique Mouldings into JaiRaj

Plastochem, and expansion into high-growth sectors like electric vehicles and drone

manufacturing. Mr. Chawla champions a customer-centric approach that emphasizes engineering

collaboration, on-time delivery, and continuous innovation in advanced polymer applications. His

commitment to quality and operational excellence has earned Jairaj Group recognition from major

OEMs including Endurance Technologies, Gabriel India, and Tenneco Automotive, along with

industry accolades and inclusion in Forbes India's DGEMS 2024 list. Under his stewardship,

Jairaj Group continues to invest in R&D, value engineering capabilities, and sustainable

manufacturing practices that position the company as a strategic partner for complex polymer

engineering challenges.