Enterprises across automotive, defense, aerospace, and industrial machinery sectors depend heavily on precision-engineered components to ensure durability, compliance, and performance. As demand for these high-quality components grows, India has emerged as a global hub, serving OEMs and Tier-1 clients worldwide.

In fact, India’s automotive aftermarket is projected to reach USD 14 billion by 2028 (INR 1,03,000 crore), supported by increasing vehicle ownership and growing demand for aftermarket services.

This article explores the leading auto parts companies in India, highlighting their innovations and key contributions to the global automotive supply chain.

Key Takeaways

- India is a global leader in cost-effective, high-quality auto parts for OEMs and Tier-1 suppliers.

- Indian manufacturers offer diverse auto parts, ensuring compliance and performance across industries.

- India’s strategic manufacturing hubs offer cost savings, faster lead times, and reliable global supply chains.

- Choose manufacturers with strong R&D capabilities, global certifications, and the ability to meet compliance standards for reliability.

- Partnering with Indian auto parts manufacturers ensures reliability, quality, and long-term success in your supply chain.

Why Auto Parts Manufacturers Are Crucial to the Automotive Sector

Auto parts manufacturers form the backbone of the automotive supply chain. They ensure that every component meets performance and compliance standards critical to safety and efficiency.

Their role goes beyond production. Leading manufacturers provide design collaboration, prototyping, and lifecycle support. These capabilities help enterprises optimize performance, reduce downtime, and ensure compliance across global markets.

JaiRaj Group plays a key role in this field, offering high-quality automotive solutions like brake pedals and accelerator pedal assemblies. With precision tooling, JaiRaj ensures automotive components meet the highest standards of reliability, performance, and compliance.

Also Read: Injection Moulding Plastic Components Manufacturer and Exporters in India

Why India is a Global Auto Component Manufacturing Hub

India’s position in the global auto supply chain is no accident. The country combines cost efficiency, skilled engineering talent, and an ecosystem of suppliers across major industrial clusters.

The following factors contribute to its leadership:

- Skilled Workforce: A large pool of engineers and technicians ensures expertise in complex manufacturing and compliance-driven production.

- Global Certifications: Leading companies maintain ISO, IATF, and CE certifications, assuring clients of international quality and safety standards.

- Strategic Location: Proximity to Asia-Pacific and Europe provides global OEMs with cost-effective sourcing opportunities.

- Diverse Capabilities: From plastics to forging and electronics, Indian firms provide complete auto component solutions under one roof.

5 Key Categories of Auto Parts Manufactured in India

Indian manufacturers produce a wide variety of components critical for automotive, defense, and aerospace applications, ensuring system-level performance and reliability. Here are the key categories of components:

- Powertrain Components: These include engine parts, crankshafts, pistons, and gears, designed for durability, efficiency, and performance across automotive and industrial applications.

- Electrical & Electronics: Components such as batteries, wiring harnesses, sensors, and control modules are manufactured to meet international compliance and performance standards.

- Chassis & Suspension: Springs, fasteners, precision brackets, and shock absorbers designed for high durability and structural stability in vehicles and industrial machinery.

- Interior & Exterior Parts: Components like panels, trims, lighting, and seating systems offer design flexibility while ensuring compliance with global safety and comfort standards.

- Advanced Polymers & Plastics: Lightweight thermoplastic and composite components that promote efficiency, sustainability, and reduced vehicle mass, contributing to overall energy savings.

Also Read: Exploring India’s Leading Auto Parts Manufacturers in Key Locations

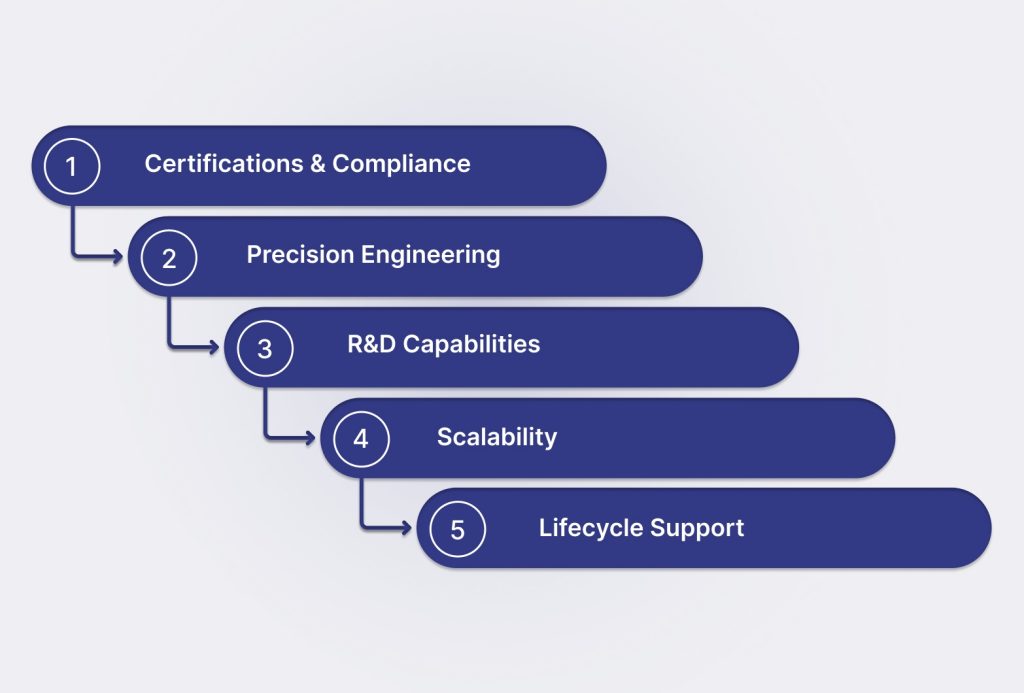

5 Essential Qualities of an Indian Auto Parts Manufacturer

Enterprises must look beyond price when selecting a partner. A reliable manufacturer offers technical expertise, compliance, and the ability to meet stringent standards. Key qualities include:

- Certifications & Compliance: Certifications such as ISO, IATF, and CE ensure that products meet international quality and safety standards in automotive manufacturing.

- Precision Engineering: Components must meet tight tolerances and quality specifications, particularly for applications in defense and aerospace where failure is not an option.

- R&D Capabilities: A strong R&D-driven approach allows manufacturers to provide in-house tooling, prototyping, and design collaboration to innovate and meet shifting industry needs.

- Scalability: The ability to deliver consistent quality at both low and high volumes ensures suppliers can meet fluctuating production demands while maintaining performance.

- Lifecycle Support: A comprehensive approach from design to after-sales ensures continuity and reliability, helping enterprises optimize product lifecycles and reduce downtime.

Next, we’ll examine the top auto parts companies in India, known for their precision and global reach.

Top 10 Auto Parts Manufacturers in India

India is home to some of the most reliable and innovative auto parts manufacturers in the world. In this section, we highlight the leading companies shaping the future of automotive manufacturing with precision and compliance-driven solutions.

1. JaiRaj Group

JaiRaj Group is an MSME with over 35 years of experience in specializing in manufacturing precision plastic components, sheet metal parts, assemblies, and industrial solutions. With in-house R&D and modern facilities across Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand, the company has earned a strong reputation for technical expertise in the automotive and aerospace sectors.

Certified with ISO-9000, ISO-14000, IATF, and CE, JaiRaj Group consistently delivers high-quality plastic components that meet global standards.

- Established: 1985

- Headquarters: Faridabad, Haryana, India

- Key Products & Applications: Precision plastic components, sheet metal parts, assemblies, and aerospace thermoplastic components.

- USP: Advanced material expertise, precision tooling, and in-house R&D capabilities.

- Industries Served: Automotive, defense, aerospace, industrial machinery, and consumer appliances.

Key Strengths:

- Advanced Material Expertise: Specializing in PP, ABS, PC/ABS, nylons, POM, TPEs, and high-performance composites, JaiRaj Group offers lightweight, durable, and cost-effective plastic components that meet the most stringent industry standards.

- Precision Tooling and Manufacturing: With in-house tooling and plastic mold development, JaiRaj ensures tight tolerances, smooth surface finishes, and consistent part quality. Their early design collaboration with clients reduces rework and accelerates production timelines.

- Diverse Manufacturing Processes: Offering plastic injection molding, blow molding, rotational molding, extrusion, assembly, JaiRaj can deliver tailored solutions for complex plastic components.

Important Product Segments:

- Brake & Accelerator Pedals

- Mobility Plastic Seating Solutions

- Shockers & Suspension Components

- Plastic Bellows & Struts

- Interior & Exterior Accessories

- Precision Components from Advanced Polymers

Why JaiRaj Group Stands Out?

For OEMs and Tier-1 suppliers, partnering with JaiRaj means reliable supply, precise engineering, and reduced operational risk. The material selection, design collaboration, manufacturing, and quality assurance, positions JaiRaj Group among the top plastic auto parts manufacturers in India.

2. Samvardhana Motherson International Limited (Motherson Group)

Samvardhana Motherson specializes in automotive components like wiring harnesses and plastic parts. The company has grown into a global leader, serving OEMs worldwide with interior and exterior plastic components critical for vehicle functionality and aesthetics.

- Established: 1986

- Headquarters: Noida, Uttar Pradesh

- Key Products & Applications: Plastic parts, automotive modules, polymer solutions, and electrical systems.

- USP: Tier-1 global supplier with extensive capabilities in plastic automotive solutions.

- Industries Served: Automotive, aerospace, industrial machinery.

3. Varroc Engineering Limited

Varroc Engineering manufactures high-performance plastic parts for automotive applications, including exterior lighting systems and powertrains. The company is known for its innovation and quality standards, serving both domestic and international OEMs.

- Established: 1990

- Headquarters: Pune, Maharashtra

- Key Products & Applications: Plastic lighting systems, electrical systems, and automotive components.

- USP: Innovation in automotive lighting and plastic engineering solutions.

- Industries Served: Automotive, aerospace, and mobility solutions.

4. Lumax Industries Limited

Lumax Industries is a key player in automotive lighting and plastic components. They manufacture headlamps, tail lamps, and interior and exterior plastic parts, focusing on sustainability and innovation.

- Established: 1945

- Headquarters: Gurgaon, Haryana

- Key Products & Applications: Plastic lighting systems, injection molded components, and automotive assemblies.

- USP: Pioneers in automotive plastic solutions with lighting and trim parts.

- Industries Served: Automotive, industrial applications.

Also Read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

5. Minda Industries Limited

Minda Industries produces a variety of plastic parts for vehicle interiors and exteriors, such as instrument panels and door trims. The company focuses on technology and innovation, delivering high-quality components to OEMs.

- Established: 1958

- Headquarters: Gurugram, Haryana

- Key Products & Applications: Plastic switches, horns, lighting systems, and seating components.

- USP: Strong expertise in plastic automotive electrical systems.

- Industries Served: Automotive, defense, industrial machinery.

6. Supreme Treon Private Limited

Supreme Treon manufactures plastic automotive parts, including bumpers, panels, and trim components. The company is known for its precision and innovative solutions, ensuring quality and reliability.

- Established: 1981

- Headquarters: Mumbai, Maharashtra

- Key Products & Applications: Plastic automotive components, molding, and polymer parts.

- USP: Expertise in precision plastic molding and automotive components.

- Industries Served: Automotive, industrial machinery.

7. Bright Autoplast Limited

Bright Autoplast, a Sintex Group subsidiary, specializes in interior and exterior plastic components. They focus on high-quality standards and durability, providing tailored solutions to meet OEM needs.

- Established: 2007

- Headquarters: Chennai, Tamil Nadu

- Key Products & Applications: Plastic automotive interiors, trims, and bumpers.

- USP: Leading supplier of plastic interior parts for global OEMs.

- Industries Served: Automotive, industrial applications.

8. Machino Plastics Limited

Machino Plastics manufactures plastic injection-molded components, including exterior trims and dashboards. The company is known for its quality and strict adherence to automotive standards.

- Established: 1987

- Headquarters: Gurgaon, Haryana

- Key Products & Applications: Plastic bumpers, interior panels, and molding components.

- USP: Known for quality plastic parts and innovative automotive solutions.

- Industries Served: Automotive, industrial applications.

9. Tata AutoComp Systems Limited (TACO) – Interiors and Plastics Division

TACO’s Interiors and Plastics Division manufactures plastic components for vehicle interiors and exteriors, such as interior trims and instrument panels. Known for sustainable practices and innovative technologies.

- Established: 1998

- Headquarters: Pune, Maharashtra

- Key Products & Applications: Plastic interior parts, automotive trim, and seating solutions.

- USP: Comprehensive expertise in automotive plastic solutions across interior and exterior applications.

- Industries Served: Automotive, aerospace.

10. MINDA TG Rubber Pvt. Ltd.

MINDA TG Rubber specializes in rubber and plastic components, including sealing parts and weather strips. They are a trusted supplier for multiple OEMs, meeting stringent quality standards.

- Established: 1958

- Headquarters: Bawal, Haryana

- Key Products & Applications: Plastic seals, rubber-plastic composites, and automotive assemblies.

- USP: Specializes in rubber-plastic hybrid solutions for automotive OEMs.

- Industries Served: Automotive, industrial machinery.

Now, it’s crucial to understand how to select the right partner who aligns with your quality, compliance, and production needs.

How to Choose the Right Auto Parts Manufacturer in India?

Selecting the right auto parts manufacturer is critical to ensuring that your components meet performance, quality, and compliance standards. Selecting a reliable manufacturer involves considering factors such as:

- Certifications & Compliance: Ensure that the manufacturer has certifications like ISO, IATF, and CE.

- Expertise: Assess the manufacturer’s experience in your specific industry, such as aerospace, defense, or automotive.

- R&D and Prototyping Capabilities: Evaluate their research and development capabilities, including in-house tooling and prototyping.

- Production Capacity: Consider whether they can handle both high-volume and low-volume production based on your needs.

- Client References: Check their portfolio and past partnerships with leading OEMs to gauge reliability.

Choosing the right auto parts company in India ensures quality, compliance, and performance. JaiRaj Group stands out with advanced R&D and precision tooling. As a leading plastic auto parts manufacturer, JaiRaj delivers high-quality, lightweight, and durable components for the automotive industry.

Conclusion

India has solidified its role as a global leader in the auto parts manufacturing industry, providing enterprises with high-quality, reliable, and cost-effective solutions. Partnering with the right auto parts company in India offers several advantages in performance and compliance, including:

- Improved durability through components designed to meet demanding performance standards and endure harsh conditions.

- Prolonged operational life thanks to precision engineering and manufacturing processes.

- Cost optimization by minimizing maintenance needs, improving efficiency, and streamlining logistics and production.

When refining your plastic component sourcing strategy, partnering with JaiRaj Group provides access to cutting-edge R&D, certified quality, and precision-focused plastic manufacturing. With facilities in Manesar, Sanand, and Aurangabad, we provide enterprises the flexibility to assess, prototype, and scale compliant auto parts solutions.

Get in touch with JaiRaj Group to discover the best plastic auto parts solutions tailored to your industry needs.

FAQs

1. Why are Indian auto parts manufacturers considered reliable for global OEMs?

Indian manufacturers offer cost-effective solutions, technical expertise, and global certifications like ISO and IATF, meeting strict compliance and performance standards for OEMs worldwide.

2. What factors should be considered when choosing an auto parts manufacturer in India?

Look for manufacturers with strong R&D, global certifications, precision tooling, and the ability to meet specific industry requirements, ensuring long-term reliability and performance compliance.

3. What are the key sectors served by Indian auto parts manufacturers?

Indian manufacturers cater to automotive, aerospace, defense, industrial machinery, and heavy equipment, providing high-quality components that meet global safety and performance standards.

4. What quality certifications should you look for when selecting an auto parts manufacturer in India?

Ensure the manufacturer holds ISO 9000, IATF 16949, ISO 14000, and CE certifications, guaranteeing global compliance with quality, safety, and environmental standards.

5. How do Indian auto parts manufacturers maintain competitive pricing while ensuring quality?

Indian manufacturers achieve cost-effectiveness by utilizing advanced manufacturing processes, skilled labor, and economies of scale, all while maintaining strict quality control and international certifications.

6. What are the environmental benefits of using thermoplastic composites in aerospace?

Thermoplastic composites are recyclable and sustainable, reducing material waste and supporting the aerospace industry’s green initiatives by cutting down on emissions and supporting eco-friendly designs.