Insert molding is a precision manufacturing technique that embeds metal components into thermoplastics, producing strong, lightweight, and high-performance parts. It is widely used in automotive, aerospace, medical devices, consumer electronics, and defense sectors to improve durability and reduce assembly steps.

The global custom insert molding market was valued at around USD 0.99 billion in 2024 and is expected to reach USD 2.21 billion in 2033, growing at a CAGR of 10.4%. This growth highlights the increasing need for reliable, high-precision components across industries.

Effective insert molding depends on accurate insert placement, suitable material selection, and controlled processing to deliver consistent quality.

This guide explores the process, material considerations, design tips, and applications to help manufacturers and procurement teams make smarter, cost-effective decisions.

Key Takeaways:

Insert molding embeds metal into plastic to create strong, durable, and precise parts while reducing assembly steps.

Selecting compatible plastics and designing secure molds ensures part strength, proper bonding, and reliable performance.

The process involves precise insert placement, high-pressure plastic injection, controlled cooling, and post-processing to maintain quality.

Insert molding is widely applied in automotive, aerospace, medical devices, electronics, and defense for critical, high-performance components.

It lowers assembly costs, enhances durability, supports lightweight designs, and delivers consistent, high-quality parts.

What is Insert Molding?

Insert molding is an advanced manufacturing technique that combines the strength of metal with the versatility of plastic in a single component. By embedding metal inserts directly into thermoplastic during the molding process, this method produces parts that are strong, durable, and dimensionally precise.

Unlike traditional assembly methods that require separate fastening or welding, insert molding streamlines production, reduces labor, and improves part reliability.

The process is widely used across industries such as automotive, aerospace, medical devices, consumer electronics, and defense, where high-performance, precision-engineered components are critical.

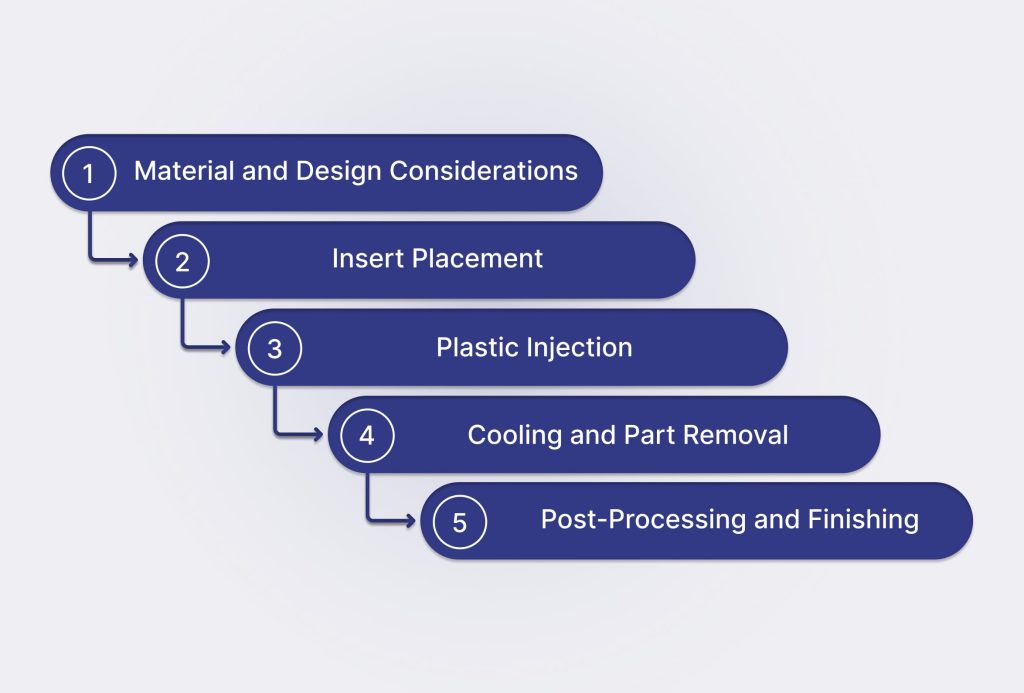

How Insert Molding Works: Step-by-Step Process

Insert molding is a method that integrates metal parts into plastic components in a single molding cycle. This approach creates strong, precise, and compact parts while reducing assembly time and cost.

Here’s a clear breakdown of each step, highlighting what matters most for consistent, high-quality results:

Step 1: Material and Design Considerations

Material selection and mold design are central to achieving strong, durable, and cost-effective components. Every design choice from resin type to mold geometry affects performance and production efficiency.

Key Considerations:

Insert Protection: Ensure inserts withstand injection temperatures and pressures.

Mold Design: Secure inserts, prevent plastic run-off, and allow smooth flow.

Material Compatibility: Select engineering resins that bond effectively with metals.

Part Geometry: Reduce stress concentrations and ensure proper encapsulation.

Example Materials:

| Material | Key Properties | Typical Applications |

|---|---|---|

| Nylon 6/66 with 30–50% GF | High strength, impact resistance, thermal stability | Brake pedals, shock absorbers |

| PBT Arnite | Chemical resistance, dimensional stability | Automotive housings, connectors |

| TPU/TPE | Flexibility, vibration damping, durability | Mobility seating, soft-touch components |

| ABS/Polycarbonate | Tough, lightweight, aesthetic | Electronics housings, automotive interiors |

Example: High-strength accelerator pedals and shock absorbers combine engineered polymers and metal inserts to meet load-bearing, safety, and long-term durability requirements.

Products from JaiRaj Group including Brake & Accelerator Pedals, Shockers & Suspension Components, Plastic Bellows & Struts, and Mobility Plastic Base Seating Solutions often rely on insert molding to meet stringent requirements for strength, durability, and long-term performance.

Step 2: Insert Placement

The foundation of any high-quality insert-molded part starts with precise insert placement. Metal inserts are positioned carefully within the mold cavity to ensure alignment, stability, and functionality. Accurate placement is crucial for consistent performance, strength, and long-term durability.

Challenges:

Misaligned inserts can result in defective parts, weak bonding, or functional failures.

Complex shapes or tight tolerances increase placement difficulty, potentially causing uneven plastic flow or voids.

High-volume production raises the risk of human error, leading to inconsistent quality and rework.

Inserts that are not secured properly may shift during injection, causing dimensional inaccuracies or cosmetic defects.

Certain insert materials may deform under high temperature or pressure if not carefully handled.

Best Practices:

Use fixtures, jigs, or automated loading systems for precise and repeatable placement, especially for complex or high-volume parts.

Inspect insert placement before every cycle to ensure accuracy and prevent defects.

Account for insert orientation, geometry, and material properties during design to simplify production and reduce risk.

Train operators in standardized procedures and implement quality checks to minimize errors in manual loading.

Conduct trial runs or simulations to verify insert stability under molding conditions before full-scale production.

Example: Brake and accelerator pedals rely on precise insert placement to maintain load-bearing capacity and safety standards.

Also Read: Automotive Interior & Exterior Plastic Parts Manufacturing: Trends and Innovations in 2025

Step 3: Plastic Injection

Once inserts are correctly positioned, molten thermoplastic is injected at high pressure to fully encapsulate the metal. This step transforms separate components into a single, unified part, eliminating additional assembly steps like welding or fastening.

Challenges:

Inserts may shift, tilt, or deform if pressure, flow, or temperature are not carefully controlled.

Voids or incomplete bonding between plastic and metal can reduce part strength.

Incompatible material selection may cause poor adhesion, warping, or thermal stress.

Best Practices:

Optimize injection parameters for each resin and part geometry to ensure proper flow and bonding.

Use engineering-grade resins compatible with metal inserts, such as Nylon 6/66 with 30–50% glass fiber, PBT Arnite, TPU, TPE, ABS, or Polycarbonate.

Simulate plastic flow, insert placement, and bonding during the design phase to prevent defects.

Design molds with precise cavities and proper supports to hold inserts securely in place.

Consider thermal expansion and stress factors to maintain dimensional stability under operational conditions.

Example: Shock absorbers, suspension components, and dashboard supports benefit from reinforced polymers that securely bond with metal inserts while reducing overall weight.

Step 4: Cooling and Part Removal

After injection, the molten plastic solidifies during controlled cooling. The mold is then opened, and the part is removed while maintaining dimensional accuracy and surface quality. This step ensures that each component meets strict tolerance and functional requirements.

Challenges:

Uneven cooling can cause warping, internal stress, or shrinkage, leading to dimensional inaccuracies.

Rough handling during mold opening may dislodge inserts or damage delicate surfaces.

Incorrect separation of sprues or excess force can create flash, burrs, or scratches on the part.

Heat-sensitive resins may crack or craze if cooling is too rapid.

Best Practices:

Incorporate uniform cooling channels in molds to ensure consistent temperature distribution and minimize warping.

Handle parts carefully during mold opening and use proper tools to separate sprues cleanly without damaging the component.

Apply gradual cooling for heat-sensitive or high-performance resins to prevent cracking, crazing, or surface defects.

Inspect parts immediately after removal to catch any defects early and reduce downstream rework.

Example: Plastic bellows and struts require uniform cooling to maintain proper fit in automotive assemblies.

Step 5: Post-Processing and Finishing

Post-processing enhances both the functional and aesthetic qualities of insert-molded parts. This stage may include deburring, polishing, heat treatment, or additional assembly.

Challenges:

Over-processing can reduce part strength, deform inserts, or cause micro-cracks in the plastic.

Inconsistent finishing may result in surface defects, burrs, or misaligned inserts, affecting both aesthetics and functionality.

Variations in handling or workflow can introduce damage during trimming, polishing, or heat treatment.

Manual finishing increases the risk of errors, especially for complex geometries or high-volume production runs.

Best Practices:

Use automated or CNC finishing to ensure precision, consistency, and repeatability.

Conduct thorough inspections for dimensional accuracy, proper insert alignment, and surface quality after each step.

Integrate post-processing seamlessly into the production workflow to minimize handling, reduce cycle time, and maintain efficiency.

Apply appropriate deburring, polishing, or heat treatment techniques based on material type and part function.

Train operators on handling critical parts to prevent scratches, warping, or insert displacement.

Example: Mobility plastic base seating solutions undergo post-processing to ensure ergonomic support, smooth surfaces, and durability under repeated load.

This combination of metal and plastic in a single component allows manufacturers to deliver high-strength, lightweight, and reliable parts while reducing assembly steps, minimizing errors, and ensuring consistent quality for OEMs and Tier-1 suppliers.

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

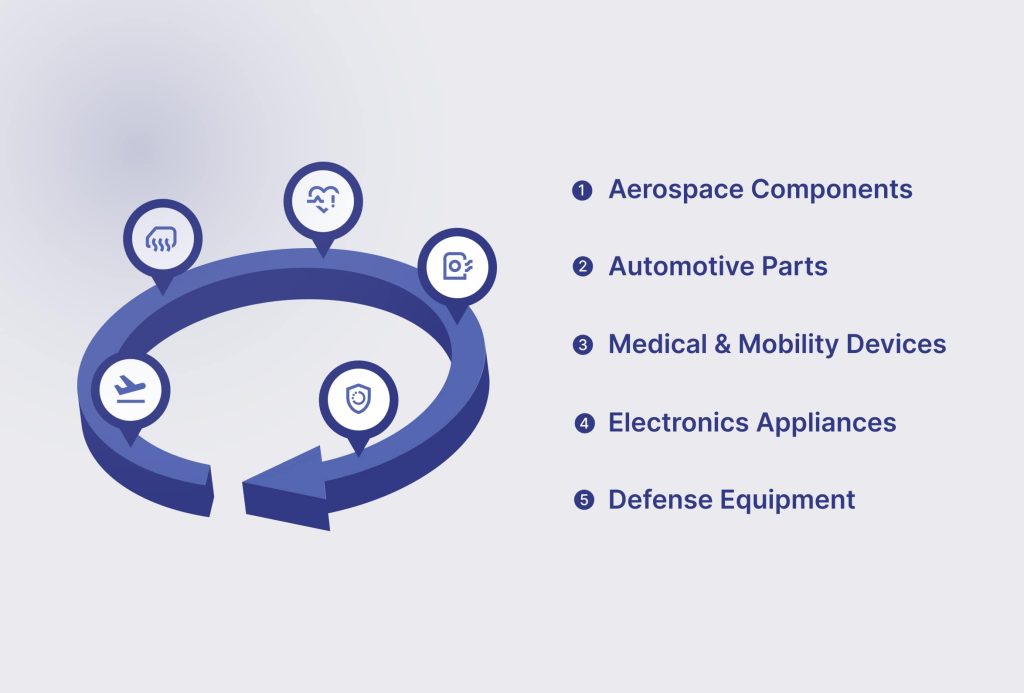

How Insert Molding Helps Industries: Key Applications

Insert molding combines plastic components and metal in a single component, producing durable, lightweight, and precision-engineered parts.

Its versatility allows industries to meet strict performance, regulatory, and aesthetic requirements while optimizing production efficiency.

To see how insert molding delivers value across sectors, let’s explore its applications and the benefits it brings to each industry:

1. Aerospace Components

FST (flame, smoke, toxicity)-compliant ducts, panels, and insulation mounts deliver reduced weight, high strength, and compliance with aviation safety standards.

Precision molding ensures dimensional accuracy under high-temperature conditions.

2. Automotive Parts

Brake and accelerator pedals, shockers, suspension components, and dashboard parts are manufactured with consistent quality, structural reliability, and reduced weight for better fuel efficiency.

Tight tolerances and durable metal integration support high-volume production and long-term performance.

3. Medical and Mobility Devices

Plastic base seating solutions for scooters, e-bikes, and EVs provide high precision, ergonomic design, and structural integrity.

These components ensure safe, reliable operation and are optimized for repeated load durability.

4. Consumer Electronics & Appliances

Structural and aesthetic parts for refrigerators, washing machines, display housings, and control panels offer clean finishes, strong performance, and seamless integration of metal inserts.

Heat resistance and dimensional stability maintain quality over repeated use.

5. Defense Equipment

Military-grade polymer parts for vehicles, UAVs, and ground systems provide high impact resistance, precise fit, and durability in harsh environments.

Reliable metal integration ensures performance for mission-critical applications.

Also Read: Injection Moulding Plastic Components Manufacturer and Exporters in India

Insert Molding: Reliable Solutions for High-Performance Components

Insert molding is a versatile manufacturing method that combines plastic and metal elements in a single component, delivering durability, precision, and cost efficiency.

The process enables the production of complex parts with strong mechanical properties, consistent quality, and functional features tailored to industry requirements.

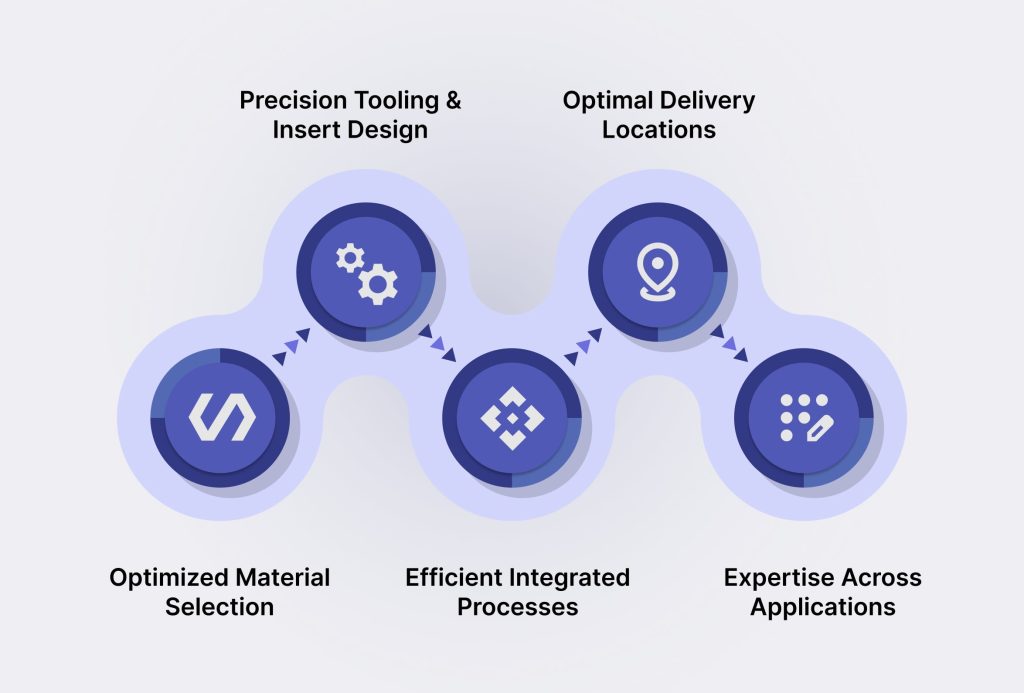

JaiRaj Group has developed its insert molding expertise around the key factors that drive successful manufacturing:

1. Optimized Material Selection

JaiRaj works with a wide variety of plastics and metal inserts, including ABS, PC, PP, nylons, and stainless steel. This ensures components are durable, lightweight, and high-performing. Rapid in-house testing allows quick validation of new material combinations.

2. Precision Tooling and Insert Design

Early Design for Manufacturability (DfM) reviews and in-house tooling ensure accurate insert placement and reduce errors. Simulation and prototyping accelerate validation and help meet tight program timelines.

3. Integrated Processes for Efficiency

For OEMs and Tier-1 suppliers, combining insert molding with overmolding, assembly, and finishing under one roof allows the production of complex components with strong inserts, superior surface finishes, and precise functional features, all in a single streamlined workflow.

4. Strategic Locations for Faster Delivery

With plants in Faridabad, Manesar, Aurangabad, Sanand, and Rudrapur, JaiRaj is close to India’s key automotive and industrial hubs. This reduces lead times, lowers logistics costs, and provides backup capacity during disruptions.

5. Proven Expertise Across Applications

With over 35 years of experience and certifications like IATF 16949, ISO, and CE, JaiRaj delivers insert-molded components that meet strict quality and regulatory standards. Key applications include:

JaiRaj provides more than just components. By focusing on quality, cost control, and program continuity, it acts as a reliable partner for suppliers and OEMs managing high-stakes manufacturing programs.

Conclusion

Insert molding plays a crucial role in creating strong, lightweight, and cost-efficient components for multiple industries. For OEMs and Tier-1 suppliers, the goal is not just to understand the process but to execute it in a way that reduces risk, controls costs, and keeps production reliable.

Companies that apply advanced molding technology, in-house mold development, and certified quality systems consistently achieve:

Predictable costs by minimizing scrap, tooling rework, and logistics expenses.

Faster product launches through efficient Design for Manufacturability (DfM) reviews and smoother part approvals.

Stable supply chains that handle material fluctuations and regional disruptions.

If you are planning a new project or updating existing components, connect with JaiRaj Group for a DfM review or visit their plants in Manesar, Sanand, or Aurangabad.

Reach out to JaiRaj Group to discuss your requirements.

FAQs

1. What factors influence the cost of insert-moulded components?

Costs depend on tooling design, material choice, part complexity, and production volume. Metal inserts and precise molds increase upfront costs, while cycle time and finishing affect per-piece pricing. Knowing these factors helps plan budgets effectively.

2. How does tooling design impact program timelines?

Proper tooling ensures correct insert placement and reduces rework. Early Design for Manufacturability reviews help validate parts faster and keep production schedules on track.

3. When is insert molding the preferred process?

Insert molding is ideal for combining plastic with metal or other materials in a single part, reducing assembly steps, and improving strength or functionality. It is useful when durability and integrated features matter.

4. What should OEMs look for in an insert molding supplier?

Suppliers should have in-house tooling, material expertise, process control, and relevant certifications. Integrated finishing and multiple facilities improve quality, reliability, and supply continuity.

5. Is multi-supplier sourcing important for insert molding?

Yes. Having multiple suppliers for resin, inserts, or tooling protects production from disruptions, price changes, and capacity limits, ensuring consistent supply.

6. How should OEMs evaluate total cost of ownership for insert molding?

TCO includes tooling, inserts, assembly, finishing, logistics, and potential rework. Evaluating suppliers based on TCO ensures predictable budgets, smoother launches, and long-term value.