Choosing a reliable and efficient supplier is crucial when it comes to choosing a plastic injection molding supplier for your manufacturing needs. An experienced supplier ensures consistent product quality, precision, and timely delivery, critical factors for industries that require high-performance plastic components.

According to Grand View Research, the global injection molding market size is projected to reach USD 462,437.7 million (INR 36.58 lakh crore) by 2033. This growth underscores the increasing demand for specialized injection molding services across various industries.

In this blog, we will explore key factors to consider when selecting a plastic injection molding supplier, providing you with actionable insights to make the right decision.

Key Takeaways

- A reliable supplier ensures consistent product quality, on-time delivery, and effective communication.

- Material selection flexibility is key for meeting specific application needs and optimizing component performance.

- Assess a supplier’s production capacity to ensure they can scale with your project’s demands.

- Certifications like ISO 9001, IATF, and CE guarantee compliance with industry standards for quality and safety.

- Strong after-sales support is essential for resolving issues and maintaining product performance over time.

Importance of Choosing the Right Injection Molding Service for Auto Parts Manufacturers

The goal of choosing the best injection molding supplier is to work with a partner who can satisfy your unique production requirements while guaranteeing excellent outcomes. The following points highlight why this decision is critical for automotive, defense, and industrial manufacturers.

1. Ensures High-Quality Production

A reliable supplier ensures that your injection mold components meet industry-specific quality standards, delivering consistent results that adhere to required tolerances and specifications.

2. Improves Time-to-Market

Choosing the right supplier helps streamline production processes, ensuring that parts are produced on time and reducing delays in your overall project timeline.

3. Offers Advanced Technology and Expertise

The right supplier will have access to the latest injection molding technology, improving precision and efficiency, while also offering expert knowledge to support your project needs.

4. Reduces Long-Term Costs

Collaborating with a seasoned supplier guarantees economical manufacturing, curtailing material waste and minimizing the requirement for costly quality control procedures or rework.

5. Supports Scalability and Flexibility

A good supplier can scale production based on your changing needs, whether you require small batches for prototyping or large volumes for mass production.

Achieve consistent quality and high precision in your brake & accelerator pedals and shockers & suspension components with Jairaj Group’s advanced injection molding. Our process, utilizing multi-cavity molds and tight tolerance control, ensures the production of automotive parts that meet the exacting standards of OEMs and Tier-1 suppliers for performance, durability, and reliability.

Also Read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

Essential Questions To Ask Potential Injection Molding Suppliers

Asking the right questions when choosing an injection molding supplier ensures that your needs are met with precision and reliability. The following questions are essential to assess their capabilities.

- Production Lead Time: Ask, “What is your production lead time?” Understanding this helps you plan schedules and meet project deadlines efficiently.

- Quality Control Procedures: Inquire, “What quality control procedures do you have in place?” Inspections, testing, and certifications ensure every component meets industry standards.

- Flexibility in Production Volume: Question, “Can you handle both small and large production runs?” A flexible supplier can accommodate specialized and high-volume projects.

- Delivery and Logistics Capabilities: Ask, “What are your delivery and logistics capabilities?” Reliable shipping and timely delivery maintain a smooth supply chain and prevent delays.

- Proven Experience: Verify, “Can you provide references or case studies?” Demonstrated success with similar projects indicates the supplier’s reliability and expertise.

Also Read: Precision Components from Advanced Polymers for Automotive and Aerospace Applications

This brings us to the critical considerations when selecting the right injection molder for your production.

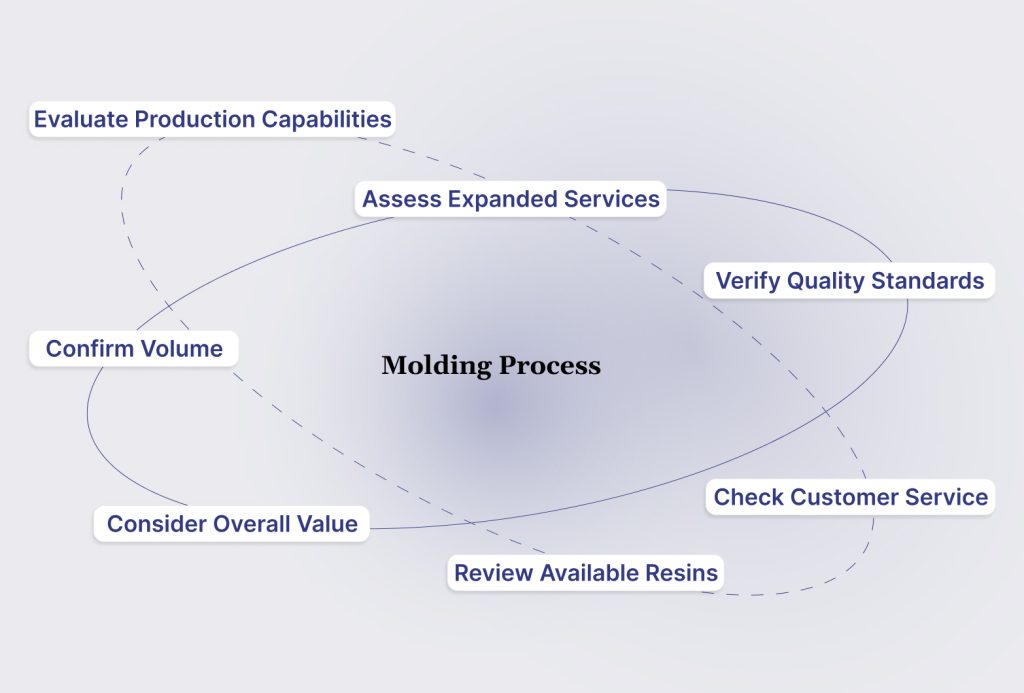

7 Steps for Manufacturers To Choose a Plastic Injection Molder

When choosing an injection molding manufacturer, it’s important to assess several factors to ensure they align with your needs. Following the steps below ensures you choose a partner that aligns with your manufacturing needs:

Step 1: Evaluate Production Capabilities and Technology

Check if the supplier has the machinery and technology to meet your project requirements. Modern injection molding machines, robotic automation, and advanced quality control are essential for high-precision parts.

If your production suffers from inconsistent part quality or missed tolerances, it’s critical to partner with a supplier equipped with advanced technology. Jairaj Group uses automated, PLC-controlled systems to deliver high-precision automotive and defense components, ensuring every part meets strict OEM and Tier-1 specifications. Our expertise in thermoplastics ensures repeatable accuracy and dimensional stability from automotive pedals to brackets.

Step 2: Assess Expanded Services

Determine whether the supplier offers additional services like custom molding, design support, assembly, or packaging, which can simplify your production process and reduce logistical complexity..

Step 3: Verify Quality Standards

Confirm that the supplier adheres to industry-specific quality standards and holds certifications such as ISO 9000 or IATF 16949 to ensure consistent, high-quality results.

Step 4: Check Customer Service & Communication

Evaluate responsiveness and communication efficiency. A supplier with proactive customer support can address issues promptly, keeping production timelines on track.

Step 5: Review Available Resins

Ensure the supplier provides the specific materials required for your application, from polypropylene (PP) for automotive parts to high-performance thermoplastics for defense components.

Step 6: Consider Overall Value

Look beyond price. Assess the supplier’s ability to deliver high-quality parts on time, combined with strong technical support and customer service.

Step 7: Confirm Volume and Capacity

Verify that the supplier can handle your production volumes, from small runs to large-scale manufacturing, without compromising quality or delivery schedules.

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

With these factors in mind, let’s explore how to find the ideal injection molding partner for your needs.

Find the Perfect Injection Molding Partner for Your Manufacturing Needs

When choosing a plastic injection molding supplier, it’s essential to partner with a provider that delivers high-quality, durable components and offers comprehensive solutions for your manufacturing needs.

With over 35 years of expertise, Jairaj Group stands as a trusted partner in manufacturing precision plastic components and industrial products, operating across modern facilities in Faridabad, Sanand, and Aurangabad to deliver high-quality solutions. Supported by certifications like ISO 9000, ISO 14000, and IATF, Jairaj Group ensures high standards across industries such as automotive, aerospace, and defense.

Here’s why Jairaj Group is the perfect partner for meeting your manufacturing requirements:

- Expertise in Precision Components: Jairaj specializes in brake & accelerator pedals, braking system components, and shockers & suspension components, ensuring precise performance for automotive applications.

- Diverse Product Range: From interior & exterior accessories to precision components from advanced polymers, Jairaj offers a wide variety of molded parts for various industries.

- Advanced Injection Molding Technology: With cutting-edge plastic injection molding capabilities, Jairaj ensures high-quality, durable components that meet your industry’s exact standards.

- Sustainability Focus: By offering solar plastic components, Jairaj helps meet the growing demand for environmentally friendly products in the industrial and automotive sectors.

- Proven Quality & Compliance: Jairaj adheres to global quality standards and offers ISO-certified processes for reliable, high-quality results.

By integrating in-house R&D and advanced production capabilities, Jairaj Group delivers customized, durable solutions that meet the specific needs of OEMs and Tier-1 suppliers worldwide.

Conclusion

When choosing a plastic injection molding supplier, it’s crucial to consider production capabilities, quality standards, available materials, and customer service. Asking the right questions and considering important aspects like communication, flexibility, and technology will help you make an informed choice that will benefit your company’s long-term success.

Companies that partner with the right injection molding supplier can expect to achieve three major benefits:

- Increased reliability with consistent, high-quality components.

- Scalable production to meet changing demands.

- Stronger collaboration with flexible, communicative support.

Partnering with a reliable plastic component manufacturer like Jairaj Group provides access to advanced injection molding technology and a wide range of plastic materials. Whether you are in automotive, mobility, defense, or aerospace, Jairaj Group’s commitment to quality and precision ensures you get the best value and performance for your investment.

Contact Jairaj Group today and find the perfect injection molding solution for your manufacturing process.

FAQs

1. How do I assess an injection molding supplier’s reliability?

Look for a proven track record, consistent delivery times, and customer reviews. A reliable supplier should meet deadlines and maintain quality standards without fail.

2. What role does material selection play in choosing a supplier?

Make sure the supplier has a large selection of materials that are appropriate for your particular use, whether it be for your parts’ strength, flexibility, or durability.

3. How can I evaluate a supplier’s capacity for high-volume production?

Check their production capabilities, available equipment, and past projects. A supplier should handle high-volume runs while maintaining quality and meeting timelines efficiently.

4. What certifications should a quality injection molding supplier have?

Look for certifications like ISO 9001, IATF, and CE, which ensure compliance with industry standards for quality, safety, and environmental management.

5. How important is a supplier’s after-sales support?

After-sales support is crucial for addressing issues, maintenance, and warranty claims. A supplier with strong support ensures long-term product performance and customer satisfaction.

6. How do I evaluate an injection molding supplier’s technological capabilities?

Assess their use of advanced machinery, automation, and innovative molding techniques. A supplier with modern technology ensures precision, faster production, and better cost efficiency.