When selecting materials for outdoor use, durability, weather resistance, and strength are critical. For industries like automotive, defense, and heavy equipment, choosing the best plastic for outdoor use can make a significant difference in performance, longevity, and cost-efficiency.

As of 2023, the plastics industry included around 50,000 businesses, with the majority being micro, small, and medium-sized enterprises (MSMEs). This underscores the growing demand for durable outdoor plastics in various sectors, driving innovation and efficiency across industries.

This blog will explore the best plastics for outdoor use, compare materials like acrylic and polycarbonate, and highlight their advantages and disadvantages to help you make an informed decision for your manufacturing needs.

Key Takeaways

- Polycarbonate is ideal for impact resistance and UV stability in harsh outdoor conditions.

- Acrylic provides clarity and UV protection, perfect for signage and visual applications.

- Polyethylene excels in chemical and moisture resistance, suitable for storage and agricultural components.

- Polypropylene offers cost-effective durability and weather resistance for outdoor furniture and industrial use.

- ABS is strong but requires UV stabilization for long-term outdoor durability.

Why Should Manufacturers Choose Plastic for Outdoor Use?

Using high-quality plastics designed for outdoor conditions is essential for ensuring the longevity and performance of your products. For automotive manufacturers and defense contractors, the materials chosen must endure exposure to environmental elements like UV radiation, moisture, extreme temperatures, and physical wear.

By selecting the best plastics, you can improve the durability and performance of your components, leading to better customer satisfaction and lower maintenance costs.

High-quality plastics also offer:

- Resistance to environmental degradation, such as UV rays and moisture.

- Strength and toughness to withstand impact, stress, and heavy use.

- Longer product lifespan, reducing the need for frequent replacements or repairs.

Suppose your automotive, aerospace, or industrial parts, like shockers & suspension components or solar plastic components, are failing under UV exposure or extreme temperatures. In that case, Jairaj Group helps with plastics like polycarbonate, polyethylene, and polypropylene that reduce weight, withstand harsh operating environments, and meet global fire, smoke, and toxicity (FST) standards, ensuring long-lasting performance and reliability.

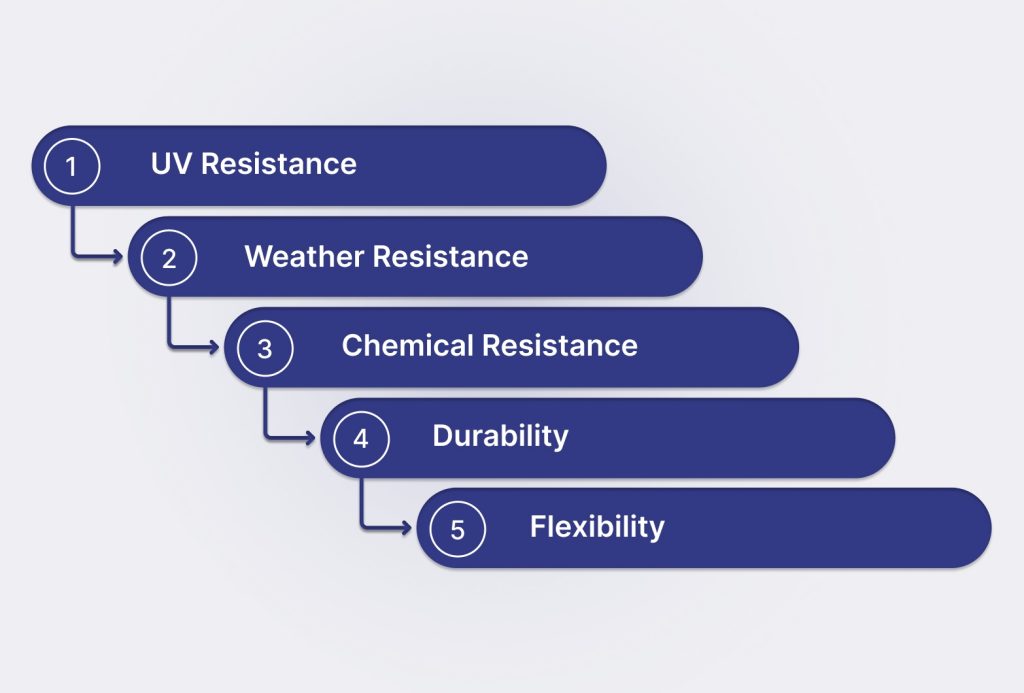

The following factors determine the plastic’s ability to withstand harsh environmental conditions, maintain functionality, and reduce maintenance costs.

- UV Resistance: Plastics must resist UV degradation to prevent brittleness or discoloration, crucial for automotive exteriors and defense components exposed to harsh sunlight.

- Weather Resistance: The ability to withstand rain, snow, and extreme temperatures ensures longevity, especially for parts like automotive windows and earth-moving equipment.

- Chemical Resistance: Outdoor plastics in industries like mobility and aerospace must resist exposure to oils, fuels, and chemicals to avoid degradation, particularly in parts like braking systems and fuel line connectors.

- Durability: Toughness is key for heavy-duty vehicle components, defense parts, and automotive accessories that must endure physical stress, impacts, and wear over time.

- Flexibility: Flexibility is important for components like automotive bumpers and defense covers, ensuring they absorb shock and handle stress without cracking.

Now, let’s look into the best plastics that are ideal for outdoor use and their applications.

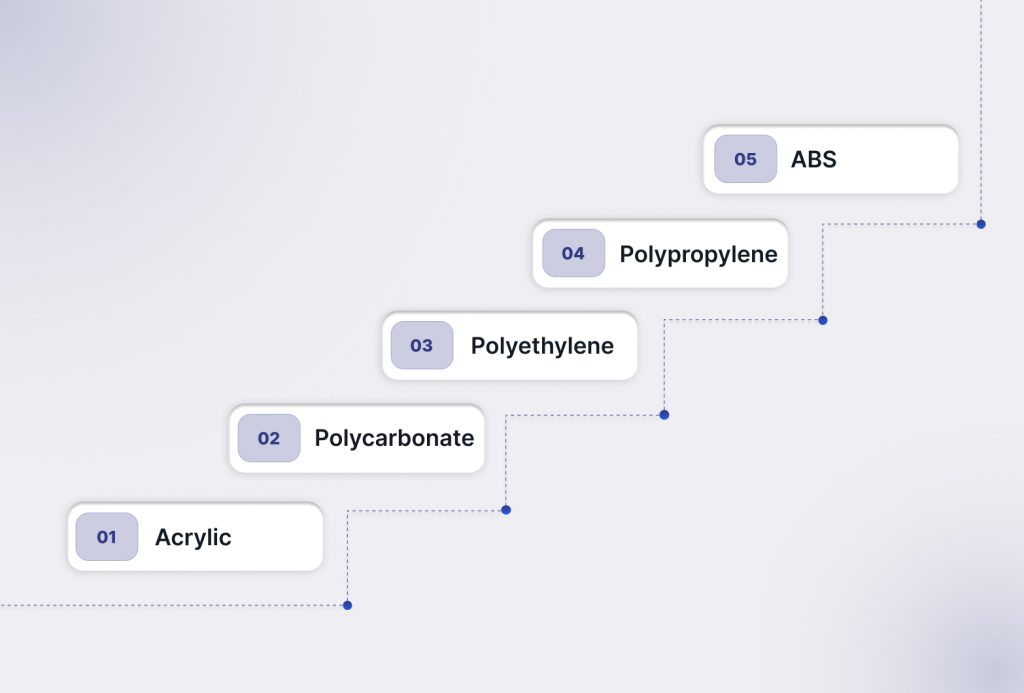

Top 5 Plastics for Outdoor Automotive and Industrial Applications

When selecting the best plastic for outdoor use, manufacturers must consider the specific demands of their applications. Below are some of the top plastics used in outdoor applications, along with their advantages and disadvantages.

1. Acrylic (PMMA)

Acrylic is a clear, UV-resistant plastic offering high optical clarity and weather resistance. It’s often used for applications like automotive windows, signage, and outdoor lighting. Acrylic is lightweight and easy to mold, making it ideal for various outdoor applications that require visibility and durability.

Advantages:

- Easy to Fabricate: Can be easily cut, drilled, and shaped for custom applications.

- Clarity Maintained Over Time: Retains its clarity and transparency even with prolonged use outdoors.

- Good Insulator: Provides electrical insulation, making it useful for electrical enclosures.

Disadvantages:

- Not Suitable for High-Impact Applications: Vulnerable to cracks from high-impact forces.

- Not Resistant to High Temperatures: Can distort or soften under extreme heat.

- Prone to Yellowing: Over time, it can discolor when exposed to UV rays without proper coating.

Application Examples:

- Outdoor signage

- Automotive lighting and lenses

- Greenhouse panels

2. Polycarbonate (PC)

Polycarbonate is a strong, impact-resistant plastic that is ideal for outdoor applications where durability is crucial, such as automotive parts and protective covers. Its high strength and ability to withstand extreme weather conditions make it a reliable choice for long-term outdoor use.

Advantages:

- Light Transmission: Offers excellent light transmission, ideal for applications requiring clarity.

- Thermal Stability: Performs well under a wide range of temperatures without losing strength.

- Scratch-Resistant Coatings Available: When coated, it provides enhanced scratch resistance, especially for automotive or external uses.

Disadvantages:

- Sensitive to Solvents: Can be damaged by exposure to certain chemicals and solvents.

- Higher Cost: More expensive than other plastics, increasing overall project costs.

- Prone to Surface Marks: While impact-resistant, polycarbonate can develop surface marks or scratches.

Application Examples:

- Automotive windshields and windows

- Protective covers for machinery

- Defense and military-grade components

3. Polyethylene (PE)

Polyethylene is a flexible, durable plastic commonly used for outdoor storage containers, agricultural components, and playground equipment. Known for its chemical resistance and ability to endure various environmental conditions, it is an affordable and widely used material in outdoor applications.

Advantages:

- Flexible and Tough: Resistant to cracking, especially in low temperatures, making it suitable for various outdoor applications.

- Low Friction: Reduces wear and tear in moving parts, ideal for industrial use.

- Good Electrical Insulation: Offers effective electrical insulation for wiring and other components.

Disadvantages:

- Not UV Stable: Without additives, it degrades quickly under UV exposure, losing its strength and color.

- Low Temperature Performance: May become brittle in very cold environments.

- Limited Color Range: Typically only available in a limited range of colors, restricting design options.

Application Examples:

- Outdoor storage containers

- Agricultural equipment components

- Playground and park equipment

4. Polypropylene (PP)

Polypropylene is a versatile plastic widely used in automotive parts and outdoor furniture. Known for its chemical resistance, durability, and light weight, it’s a cost-efficient option for products exposed to harsh environments.

Advantages:

- High Chemical Resistance: Excellent for use in environments exposed to chemicals or solvents.

- High Fatigue Resistance: Ideal for parts that experience repetitive motion or stress.

- Resistant to Water: Highly resistant to water absorption, making it ideal for outdoor and marine environments.

Disadvantages:

- Limited Heat Resistance: Melts at lower temperatures compared to other materials.

- Color Fading: Polypropylene tends to fade when exposed to sunlight for prolonged periods.

- Brittle in Cold Temperatures: Becomes more prone to cracking under freezing conditions.

Application Examples:

- Outdoor furniture

- Automotive parts and interior components

- Industrial containers and packaging

5. ABS (Acrylonitrile Butadiene Styrene)

ABS is a tough, rigid plastic commonly used in outdoor automotive and industrial applications. It offers a good balance of strength, impact resistance, and easy moldability, making it ideal for a variety of outdoor components.

Advantages:

- Impact Strength: High impact resistance makes it ideal for automotive applications.

- Good Structural Rigidity: Maintains its shape under load, making it suitable for parts that need to retain form.

- Processing Ease: Highly precise molding into intricate shapes is possible.

Disadvantages:

- UV Sensitivity: Without UV stabilizers, it can degrade under sunlight exposure.

- Vulnerable to Chemicals: Some chemicals can cause ABS to swell or degrade.

- Low Temperature Performance: Becomes brittle in cold weather, reducing its effectiveness in freezing conditions.

Application Examples:

- Automotive parts and interior components

- Consumer electronics casings

- Appliance housings

Also Read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

Understanding the specific characteristics of acrylic and polycarbonate will help you determine which is best for your applications.

Acrylic vs. Polycarbonate for Outdoor Automotive and Industrial Applications

When choosing materials for outdoor automotive and industrial applications, it’s essential to consider their performance in key areas like clarity, strength, and resistance. The following table compares acrylic and polycarbonate, helping manufacturers select the right material for their needs.

| Property | Acrylic | Polycarbonate |

| Optical Clarity | Superior optical clarity, ideal for lighting and lenses | Lower optical clarity compared to acrylic |

| UV Resistance | Excellent UV resistance, great for outdoor use | Good UV resistance but slightly less than acrylic |

| Impact Resistance | Lacks impact resistance, not ideal for high-stress components | High impact resistance, perfect for protective covers and bumpers |

| Strength & Durability | Less durable under harsh conditions | Extremely durable and strong, suitable for extreme environments |

| Ideal Applications | Automotive lighting, defense lenses | Automotive bumpers, military-grade components, aerospace, earth-moving equipment |

| Best For | Applications requiring high clarity and UV protection | Applications requiring strength, impact resistance, and durability |

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

Next, let’s explore the real-world applications of these outdoor plastics in industries like automotive and aerospace.

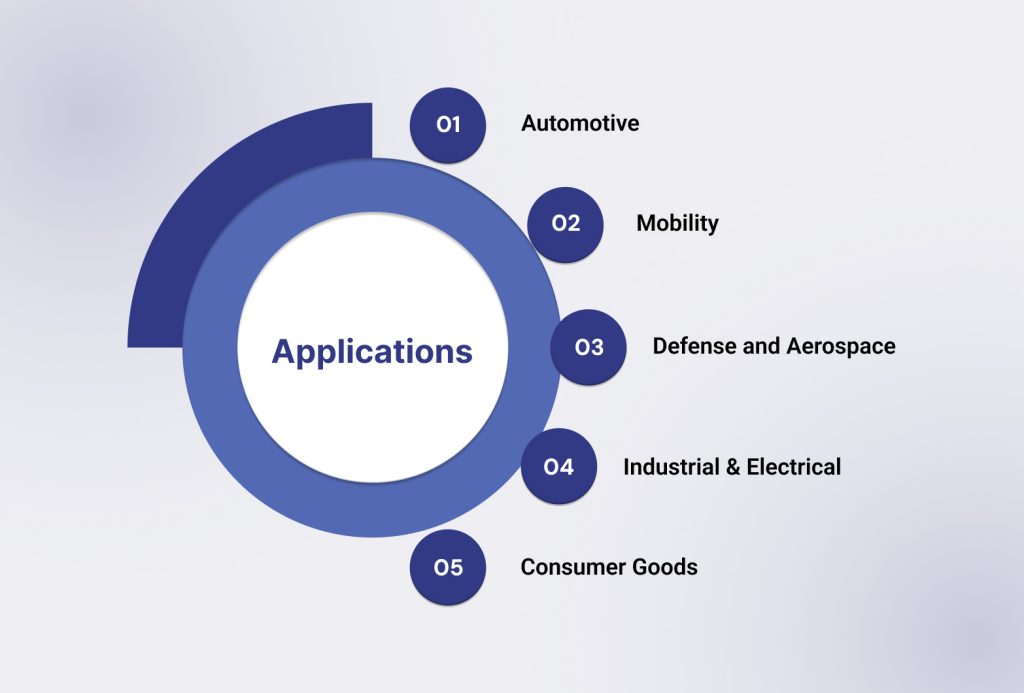

Applications of Outdoor Plastics in Automotive, Aerospace, and Industrial Manufacturing

Outdoor plastics are vital for creating durable components in various sectors like automotive and aerospace. The following applications highlight how these materials enhance performance and longevity in demanding environments.

- Automotive: Plastics like polycarbonate and acrylic are used in exterior vehicle parts, including windows, headlamp lenses, and trim, ensuring durability and impact resistance.

- Mobility: Components for scooters, e-bikes, and electric vehicles require plastics that can withstand outdoor environments. Polypropylene and polyethylene are often used for their strength and weather resistance.

- Defense and Aerospace: Military-grade plastics are used in defense equipment and aerospace components to meet stringent safety and performance standards while enduring harsh conditions.

- Industrial & Electrical: Solar components, construction equipment, and heavy machinery often rely on outdoor plastics that resist UV degradation and extreme temperatures for long-term durability.

- Consumer Goods: Outdoor furniture, playground equipment, and storage solutions are often made from polyethylene, polypropylene, or acrylic, offering durability and resistance to the elements.

Also Read: Top 10 Auto Parts Manufacturers in India

Now, let’s look at how to select the best plastics for outdoor applications in automotive and industrial sectors.

Selecting the Best Plastics for Outdoor Applications in Automotive and Industrial Sectors

For industries like automotive, defense, and heavy equipment, selecting plastics that offer durability, UV resistance, and impact strength is essential. For dependable performance, these materials must endure severe outdoor environments, chemical exposure, and physical strain. physical strain.

Jairaj Group provides high-quality, durable plastics designed for these demanding industries. With over 35 years of experience, they specialize in precision components for automotive OEMs, defense, and industrial equipment manufacturers.

Their expertise in injection molding, blow molding, and rotational molding guarantees products that meet stringent performance standards.

Why should you choose Jairaj Group for outdoor plastics manufacturing?

1. Plastic Injection Molding

Jairaj specializes in plastic injection molding for components like brake & accelerator pedals, shockers & suspension components, and braking system components. This process ensures high precision and strength, ideal for automotive and heavy-duty vehicle parts exposed to harsh outdoor conditions.

2. Plastic Blow Molding

For flexible and durable outdoor components, Jairaj uses plastic blow molding technology to create plastic bellows & struts and hand grips. These parts are essential for automotive, railway, and earthmover applications, offering resilience and flexibility under stress.

3. Plastic Rotational Molding

Roto molding is ideal for creating complex, large components such as earth movers & heavy vehicle components and mobility plastic base seating solutions. These components are crucial for industries like construction, defense, and automotive, where durability and long-term performance are critical.

4. Advanced Materials for Demanding Applications

Jairaj Group manufactures durable outdoor plastics using materials like TPE/TPV, TPU (Estane GP60D, Hytrel, Engage), PBT Arnite, Nylon 6/66 (30%-50% GF), PA 12, Polycarbonate, ABS/ABS+PC, Poly Acetal (POM), PVC/TPE, Polypropylene (PPCP), and Polyethylene (PE), ensuring top-quality solutions for demanding outdoor applications. These materials are used in manufacturing precision components from advanced polymers to ensure high durability, chemical resistance, and excellent performance in extreme conditions.

5. Comprehensive Services

From precision components to solar plastic components, Jairaj Group’s plastic welding and assembly lines technologies ensure that each part is crafted with the utmost care, reliability, and compliance with industry standards.

As a trusted partner to OEMs, Tier-1 suppliers, and specialized manufacturers, JaiRaj Group delivers customized, durable outdoor plastics from its facilities in Faridabad, Rudrapur, and Manesar, ensuring the highest quality and compliance standards.

Conclusion

In order to ensure dependable performance in challenging conditions, it is crucial to prioritize materials that offer durability, UV resistance, and impact strength when choosing the best plastic for outdoor use.

Plastics like polycarbonate for automotive windows, acrylic for solar panels, and polyethylene for heavy-duty equipment components provide the necessary toughness to endure outdoor conditions in automotive, aerospace, and defense applications.

Companies that choose the right plastic for outdoor use can expect three key benefits:

- Improved durability with UV-resistant polycarbonate in automotive and defense parts that endure weathering and impact.

- Longer service life with polyethylene and polypropylene that resist chemicals, moisture, and physical stress for earth mover parts.

- Enhanced performance with acrylic in solar plastic components, maintaining clarity and UV resistance.

Partnering with Jairaj Group gives you access to precision-engineered plastic components for demanding outdoor applications. Whether for brake & accelerator pedals, shockers & suspension components, or solar plastic components, Jairaj Group offers customized solutions that meet your industry’s specific needs, ensuring durability and long-term reliability.

Reach out to Jairaj Group to find out how high-performance plastic solutions can upgrade your outdoor manufacturing projects.

FAQs

1. What makes polycarbonate ideal for outdoor applications?

Polycarbonate is highly impact-resistant, UV-stable, and maintains strength in extreme weather conditions, making it perfect for outdoor components like windows and protective covers.

2. Why is acrylic used in outdoor signage?

Acrylic offers excellent clarity, UV resistance, and durability, making it an ideal material for outdoor signage, ensuring long-lasting visual appeal in exposed environments.

3. How does polyethylene perform in outdoor environments?

Polyethylene resists moisture, chemicals, and UV degradation, making it suitable for outdoor storage, agricultural components, and parts exposed to harsh weather conditions.

4. What are the benefits of using polypropylene outdoors?

Polypropylene offers excellent chemical resistance, weather resistance, and low-cost durability, making it a reliable material for outdoor furniture and industrial applications.

5. How does ABS perform under outdoor conditions?

ABS is strong, impact-resistant, and weatherproof, but it requires UV stabilizers for outdoor use, making it ideal for parts exposed to physical stress.

6. What should I consider when selecting plastic for outdoor use?

Consider the material’s UV resistance, impact strength, chemical resistance, and weatherability to ensure the plastic can withstand outdoor conditions while maintaining performance.