Your interior trim component arrives with visible flow lines. The impact test fails at the specified temperature. Production parts show sink marks above the ribs.

These defects trace back to one root cause: insufficient understanding of ABS plastic injection molding parameters. ABS is not a forgiving material. It demands precise temperature control, proper drying, and disciplined mold design. Deviations from best practices produce cosmetic rejects and field failures.

This guide covers ABS properties, process optimization, cost drivers, and defect prevention. You will learn how to specify ABS components correctly and evaluate supplier capability.

Quick Look

- ABS combines impact strength, stiffness, and surface finish for interior and cosmetic applications.

- Material must be dried to below 0.1% moisture before molding to prevent splay and blistering.

- Melt temperature range is 200°C to 260°C; mold temperature controls surface gloss.

- ABS costs less than polycarbonate but has lower heat resistance and UV stability.

- Common defects include sink marks, warpage, flow lines, and burn marks from improper processing.

- JaiRaj Group molds Interior & Exterior Accessories and Components and Precision Components From Advance Polymers in ABS and ABS+PC blends.

What Is ABS Plastic Injection Molding and Why It Matters

ABS is a terpolymer of acrylonitrile, butadiene, and styrene. This combination delivers impact resistance from butadiene, rigidity from acrylonitrile, and processability from styrene. It remains widely used for automotive interiors, appliance housings, and consumer goods.

ABS outperforms polypropylene in surface finish and dimensional stability. It offers a lower cost than polycarbonate when impact requirements are moderate. Material choice directly affects your part cost, cosmetic quality, and compliance with flammability standards.

Evaluating ABS for a structural or cosmetic program requires reviewing real production applications rather than relying on datasheet comparisons. JaiRaj Group manufactures ABS and ABS+PC components across programs such as Interior & Exterior Accessories and Components and Precision Components From Advance Polymers, where surface finish control, dimensional repeatability, and material validation influence long-term performance and audit readiness.

Also read: How to Choose the Right Injection Molding Supplier

Key Properties of ABS That Influence Injection Molding Decisions

ABS properties vary by grade and supplier formulation. Understanding these characteristics guides material selection and process design.

The following properties most influence your molding outcomes:

Mechanical Properties

- ABS offers excellent impact strength across a wide temperature range. This makes it suitable for parts subject to handling or minor impacts.

- Tensile strength ranges from 40 to 50 MPa depending on grade. Higher rubber content increases impact but reduces stiffness.

- Impact strength: Ranges from 200 to 400 J/m for notched Izod tests.

- Stiffness vs ductility: High-impact grades sacrifice modulus for toughness.

Thermal Performance

- ABS has a heat deflection temperature of 85°C to 105°C at 1.82 MPa. This limits its use in high-heat environments near engines or lighting.

- Continuous service temperature is approximately 70°C to 80°C. Above this range, parts may soften or distort.

- Heat deflection: Choose higher HDT grades for warmer interior locations.

- Failure mode: ABS deforms plastically before brittle fracture under heat.

Chemical and UV Resistance

- ABS is susceptible to attack by ketones, esters, and chlorinated solvents. It performs poorly with certain cleaning agents.

- Ultraviolet exposure causes discoloration and embrittlement without protection.

- Limitations: Outdoor applications require painting or UV-stabilized grades.

- Solutions: Coating with acrylic or blending with PC improves weatherability.

Surface Finish and Aesthetics

- ABS accepts textured finishes, painting, and plating exceptionally well. This makes it the preferred material for visible interior parts.

- Mold surface texture transfers faithfully to the molded part. Gloss levels can be controlled via mold temperature.

- Paintability: ABS bonds well with solvent-based and water-based paints.

- Texture control: Mold etching produces consistent matte or grained finishes.

These properties explain why ABS dominates interior applications across automotive and consumer goods.

Also read: Injection Mold Components: Understanding the Parts

When Should You Choose ABS Over Other Engineering Plastics?

The decision between ABS and alternative materials depends on your performance priorities. Compare these common alternatives against your requirements:

ABS vs Polypropylene (PP)

- ABS offers significantly higher stiffness and impact strength than PP. It also provides better surface appearance and paint adhesion.

- PP costs less per kilogram and suits chemical-resistant applications. Choose PP for non-cosmetic parts like Plastic Bellows & Struts where flexibility is needed.

ABS vs Polycarbonate (PC)

- Polycarbonate provides superior impact strength and heat resistance. It withstands 120°C+ continuous service temperatures.

- ABS costs less and molds more easily with better surface finish. Select ABS for interior trims and PC for structural or high-heat applications.

ABS vs Nylon (PA66/PA6)

- Nylon offers higher continuous service temperature and chemical resistance. It absorbs moisture, causing dimensional changes.

- ABS provides stable dimensions in varying humidity. It suits Interior & Exterior Accessories and Components where moisture exposure varies.

ABS+PC Blends

- Blending ABS with polycarbonate combines impact strength with processability. PC-ABS alloys achieve HDT values of 110°C to 120°C.

- These blends are specified for automotive interior components requiring higher heat resistance. They also improve low-temperature impact performance.

Decision Matrix

Your material choice must balance these factors against part function and total cost.

ABS Plastic Injection Molding Process – Step-by-Step Workflow

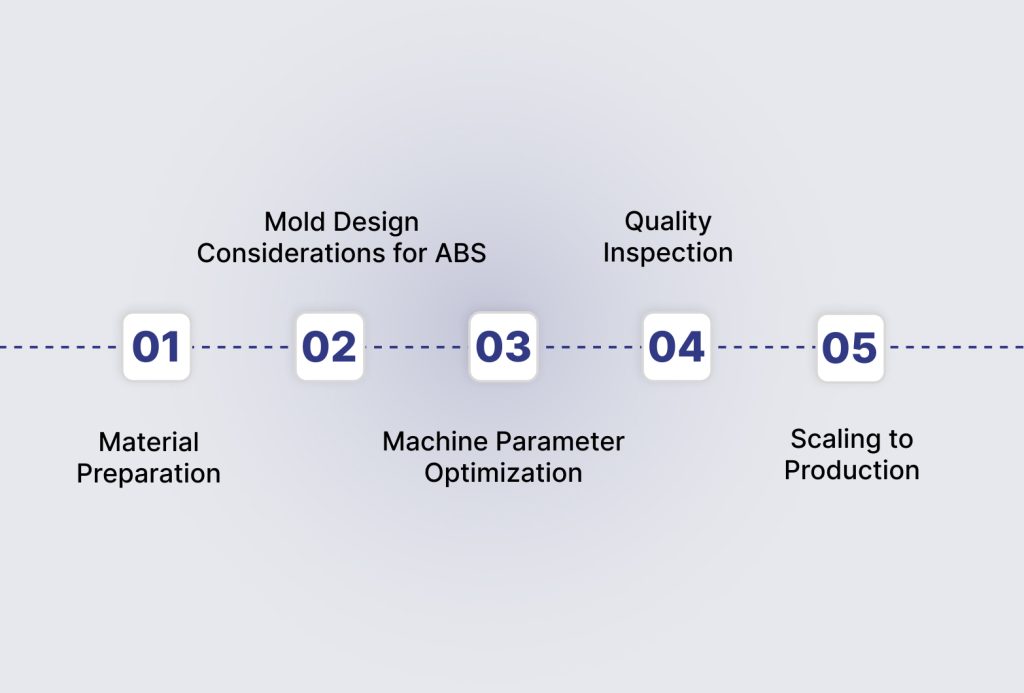

Successful ABS molding requires strict adherence to processing parameters. Deviations cause cosmetic defects and property degradation.

Follow these five steps for reliable ABS production:

Step 1 – Material Preparation and Drying

ABS is hygroscopic and absorbs moisture from ambient air. Moisture causes splay, blistering, and property loss during molding.

- Recommended moisture level is below 0.1% before processing.

- Dry at 80°C to 90°C for 2 to 4 hours using a desiccant dryer.

- Moisture calculation: Moisture % = (Initial weight – Dry weight) ÷ Initial weight × 100.

- Consequence of skipping drying: Silver streaking on parts and reduced impact strength.

Step 2 – Mold Design Considerations for ABS

ABS flows well but requires proper gate and runner design to avoid defects.

- Draft angles of 1° to 2° per side for easy ejection.

- Gate location should avoid flow hesitation and weld lines in cosmetic areas.

- Wall thickness should be uniform between 2.0 mm and 3.5 mm ideally.

- Rib design: Rib thickness should be 50% to 60% of the nominal wall to prevent sink marks.

Step 3 – Machine Parameter Optimization

ABS processes over a wide temperature range but requires precise control.

- Barrel temperature profile: 200°C to 230°C (rear) increasing to 230°C to 260°C (nozzle).

- Injection speed: Moderate to fast to prevent flow lines and short shots.

- Mold temperature: 30°C to 80°C controls surface gloss and part cooling.

- Before/After example: High injection speed causes jetting and flow lines. Optimized speed produces uniform fill without surface defects.

Step 4 – Quality Inspection and Validation

Molded parts must meet dimensional and cosmetic specifications.

- Check critical dimensions against drawing tolerances.

- Inspect surfaces under controlled lighting for flow lines, sink marks, and splay.

- Monitor Cpk for critical features; target Cpk ≥ 1.33 for stable processes.

- Implementation checklist: First article inspection, capability study, and control plan documentation.

Step 5 – Scaling to Production

Transition from trials to volume production requires process discipline.

- Reduce cycle time systematically while monitoring part quality.

- Implement tool maintenance schedules based on shot count.

- Track scrap rate and identify root causes of non-conforming parts.

- Scrap monitoring framework: Daily yield reports, Pareto analysis of defect types, corrective action tracking.

A robust process ensures consistent ABS part quality across production runs.

Also read: Blow Molding vs Rotational Molding: Key Differences Explained

Cost Factors in ABS Plastic Injection Molding

Understanding cost drivers helps you optimize part design and supplier selection. Key factors affecting ABS molding costs include:

Raw Material Cost

- ABS resin prices fluctuate with crude oil and butadiene markets. Expect $1.50 to $2.50 per kilogram for general-purpose grades.

- Price volatility: Monitor resin indexes and consider longer-term agreements.

- Grade selection: Higher impact or UV-stabilized grades increase material cost by 10% to 20%.

Tooling Cost

- Injection mold cost depends on cavity count, complexity, and steel type. A single-cavity automotive trim mold ranges from $20,000 to $50,000.

- Single vs multi-cavity: Multi-cavity tools increase upfront cost but reduce per-part price at high volumes.

- Tool life: Hardened steel tools produce 500,000+ parts; aluminum tools suit lower volumes.

Cycle Time and Throughput

- Cycle time directly affects machine cost per part. ABS cycles typically range from 30 to 60 seconds, depending on wall thickness.

- Cost per part formula: Cost per part = (Machine rate × Cycle time ÷ 3600) + Material cost + Scrap.

- Machine rate: $50 to $150 per hour, depending on tonnage and location.

Secondary Operations

- Painting, plating, or assembly adds cost to the base molded part. ABS accepts these finishes well but requires process validation.

- Painting cost: Adds $1 to $5 per par,t depending on color and coverage.

- Assembly: Snap-fit designs reduce secondary labor compared to fasteners.

Understanding ABS molding costs helps you evaluate supplier quotes accurately.

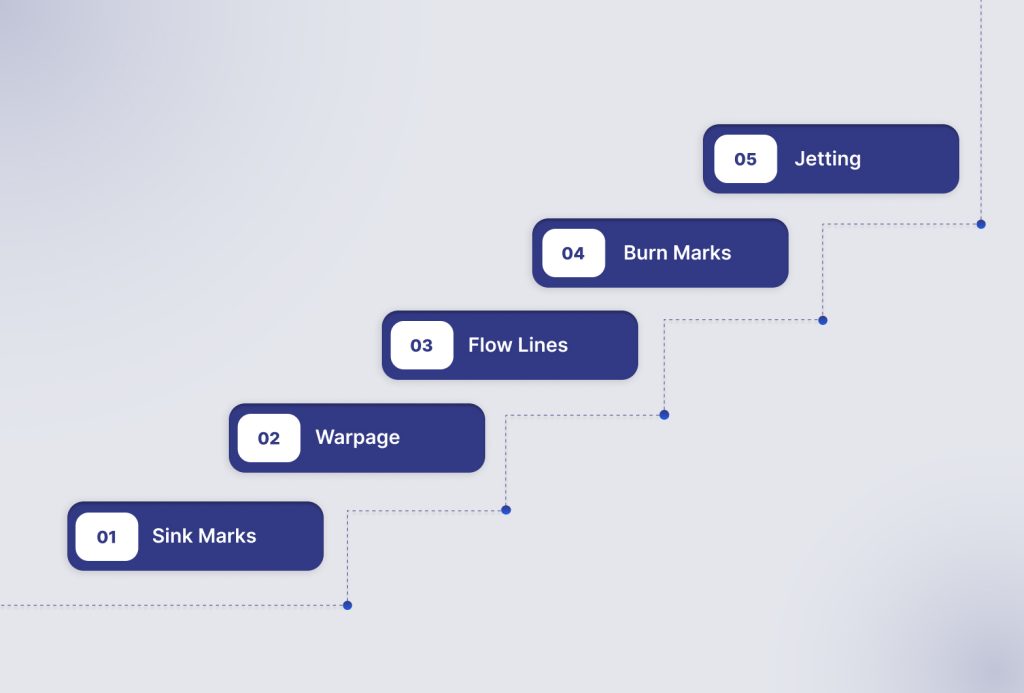

Common Defects in ABS Injection Molding and How to Prevent Them

ABS exhibits characteristic defects when processing parameters drift. Early detection prevents scrap and rework.

Address these five common defects in your quality system:

Sink Marks

- Root cause: Localized shrinkage above ribs or thick sections. Insufficient hold pressure or cooling time.

- Detection method: Visual inspection or profilometry on critical surfaces.

- Corrective action: Increase hold pressure and time. Reduce rib thickness to 50% of the nominal wall.

Warpage

- Root cause: Uneven cooling between mold halves. Differential shrinkage in oriented regions.

- Detection method: Flatness check on reference surface or fixture.

- Corrective action: Balance mold cooling circuit temperatures. Adjust ejection to prevent part distortion.

Flow Lines

- Root cause: Hesitation at changes in wall thickness. The injection speed is too slow, or the melt temperature is too low.

- Detection method: Visual inspection reveals concentric rings nearthe gate.

- Corrective action: Increase injection speed through the gate. Raise the melt temperature for better flow.

Burn Marks

- Root cause: Trapped air compressing and igniting in the mold. Poor venting at the flow front.

- Detection method: Black or brown discoloration at the end of the fill or last point to fill.

- Corrective action: Improve mold venting at flow fronts. Reduce injection speed at the end of the fill.

Jetting

- Root cause: Material shooting through an open space before contacting the mold wall. A small gate directed at a large cavity.

- Detection method: Worm-like flow pattern on the part surface opposite the gate.

- Corrective action: Enlarge the gate or reposition it to contact the mold wall immediately. Reduce injection speed.

Systematic defect prevention reduces scrap and ensures consistent part quality.

Also read: PP vs PVC: Understanding Performance and Application Differences

Best Practices for Reliable ABS Injection Molding

Adopt these practices to ensure robust ABS molding programs:

Design for Manufacturability in ABS

- Maintain uniform wall thickness between 2.0 mm and 3.5 mm. Transitions should be gradual with radii.

- Impact: Consistent wall thickness reduces sink marks and warpage. It also shortens cycle time.

Color and Cosmetic Control

- Use consistent pigment masterbatch from approved suppliers. Virgin resin lots should be tested for color shift.

- Impact: Pigment variation causes visible color differences across production batches. Controls ensure match to approved samples.

Mold Maintenance Discipline

- Schedule preventive maintenance every 50,000 to 100,000 shots. Clean vents, check cooling channels, and inspect cavity surfaces.

- Impact: Regular maintenance prevents defect drift and unplanned downtime. It extends tool life significantly.

Supplier Selection Criteria

- Evaluate supplier engineering depth for ABS processing. Request DfM feedback on wall thickness, gate location, and rib design.

- Impact: Experienced suppliers prevent design-related defects before tooling begins. They optimize parameters for your specific grade.

These practices distinguish capable ABS molders from commodity vendors.

Industry Applications of ABS Injection Molding

ABS components support visible and structural use cases across sectors.

You often select ABS when appearance and moderate strength must coexist:

Automotive Interior Components

- Dashboards and trims

- Enclosures within Interior & Exterior Accessories and Components

Appliance Housings

- Refrigerator panels and knobs

- Structural parts within Roto Moulding Components

Electrical Enclosures

- Meter covers and display housings

- Structural components within Precision Components From Advance Polymers

EV Components

- Lightweight housings

- Seating bases like Mobility Plastic Base Seating Solutions

ABS programs demand experienced molding and validation partners.

How JaiRaj Group Supports ABS Plastic Injection Molding Programs

You face launch risk, cosmetic rejection, and compliance pressure in ABS programs.

You also manage cost volatility, tooling lead times, and supplier performance consistency.

JaiRaj Group supports ABS injection molding with in-house tooling, advanced polymers expertise, and validated quality systems across industries.

- Deep injection molding capability supporting Brake & Accelerator Pedal and Braking System Components programs.

- Advanced polymer processing for Shockers & Suspension Components and Hand Grips.

- Tooling and mold development supporting Plastic Bellows & Struts, Earth Movers and Heavy Vehicle Components.

- Multi-sector expertise, including Solar Plastic Components and aerospace-grade parts.

JaiRaj Group aligns engineering, tooling, and production for reliable ABS program execution.

Conclusion

ABS plastic injection molding requires disciplined material preparation, mold design, and process control. Understanding properties, cost drivers, and defect mechanisms enables better sourcing decisions.

Properly molded ABS delivers excellent surface finish, impact strength, and value. Your ABS decisions should focus on lifecycle performance, risk mitigation, and Total Cost of Ownership.

JaiRaj Group supports ABS plastic injection molding with integrated tooling, engineering depth, and multi-industry experience.

Reach out to JaiRaj Group to discuss your requirements.

FAQs

Q. What temperature is ABS injection molded at?

ABS melts between 200°C and 260°C, depending on grade and flow requirements. The recommended barrel temperature profile starts at 200°C at the rear and increases to 240°C-260°C at the nozzle.

Q. Does ABS require drying before molding?

Yes, ABS is hygroscopic and must be dried to below 0.1% moisture. Dry at 80°C to 90°C for 2 to 4 hours using a desiccant dryer to prevent splay and blistering.

Q. Is ABS stronger than polypropylene?

ABS has significantly higher stiffness and impact strength than polypropylene. It also offers better surface finish and dimensional stability. Polypropylene provides better chemical resistance at a lower cost.

Q. How much does ABS injection molding cost?

Cost depends on part size, complexity, volume, and secondary operations. Material cost is $1.50 to $2.50 per kilogram. Tooling ranges from $20,000 to $50,000 for a single-cavity automotive mold.

Q. Can ABS be used for outdoor applications?

Unmodified ABS degrades under UV exposure, causing discoloration and embrittlement. Outdoor applications require UV-stabilized grades, painting, or co-extrusion with a UV-resistant cap layer.