In automotive, aerospace, defense, or consumer goods, manufacturers must implement rigorous injection molding quality control procedures to maintain consistency, reduce defects, and optimize production.

Recently, there has been a growing use of machine learning-driven process optimization, enabling manufacturers to determine ideal molding parameters with greater speed and accuracy, transforming quality assurance into a predictive, data-led process that minimizes waste and boosts production reliability.

This blog explores why quality control is critical in injection molding, focusing on its role across industries, factors influencing material selection, inspection stages, and best practices for maintaining top-tier production standards.

Key Takeaways

- Quality control is essential for ensuring that injection-molded parts meet industry standards and customer expectations.

- Materials like polypropylene and ABS are chosen for their durability, moldability, and cost-effectiveness in injection molding.

- Statistical Process Control (SPC) helps manufacturers monitor and control the molding process to ensure consistent product quality.

- Preventive mold maintenance is crucial to minimizing defects and extending the lifespan of molds.

- Modern quality control techniques, including automated inspections and Total Quality Management (TQM), enhance efficiency and reduce defects in production.

The Role of Quality Control in Injection Molding for Plastic Manufacturers

Without quality control, engineers in injection molding operations face the risk of defects that reduce the quality of the final product and impact safety, functionality, and customer satisfaction. Here’s why injection molding quality control matters in plastic manufacturing:

- Ensures Safety and Compliance: Injection-molded parts are critical in safety-sensitive industries like automotive and aerospace. Quality control ensures that each part meets required regulatory standards and performs reliably in critical applications.

- Prevents Costly Defects and Rework: By monitoring every stage of production, quality control prevents defects, saving money on rework and scrap, which is vital for large-scale manufacturing operations.

- Improves Product Consistency: Consistent product quality is essential for industries such as automotive and heavy equipment, where precision is necessary for optimal performance and customer satisfaction.

- Enhances Durability and Reliability: In sectors like defense, where components must withstand extreme conditions, rigorous quality control ensures that parts meet durability standards and perform in harsh environments.

- Optimizes Production Efficiency: By detecting issues early, quality control helps optimize the manufacturing process, reducing downtime and improving overall plant productivity.

In precision injection molding, even minimal deviations in melt viscosity or mold temperature can lead to warping or inconsistent part geometry.

Jairaj Group overcomes these challenges through advanced Plastic Injection Molding technology, producing components like Brake & Accelerator Pedals and Shockers & Suspension Components with exceptional dimensional stability. Using high-performance Nylon 6/66 with 33–50% glass fiber reinforcement and PBT Arnite compounds, our engineers achieve superior tensile strength, fatigue resistance, and heat tolerance.

To understand its true importance, let’s look at why quality control impacts every major industry that relies on plastic parts.

Why Quality Control is Crucial Across Industries

Quality control is a regulatory requirement in several industries that depend on injection-molded parts. Different sectors have unique needs and challenges, but all benefit from comprehensive quality control processes.

- Automotive: Automotive manufacturers rely heavily on injection molding quality control to produce parts like bumpers, dashboards, and engine components that must meet strict safety and performance standards. Consistency is crucial here, as even minor defects can lead to costly recalls or safety issues.

- Aerospace: Aerospace components must meet stringent specifications for performance, weight, and safety. Quality control ensures that every part, from brackets to casings, adheres to rigorous standards and can withstand extreme environmental conditions.

- Defense: Military-grade components must meet high durability standards and be able to perform under extreme conditions. Injection molding quality control ensures that parts like protective gear, communication systems, and weapon systems are reliable and precise.

- Industrial & Heavy Equipment: In industries such as construction, mining, and agriculture, injection-molded components must withstand harsh environmental conditions. Quality control ensures that these parts, such as heavy-duty machinery components, are durable, reliable, and safe to use.

- White Goods & Appliances: Consumer appliances like refrigerators, washing machines, and air conditioners rely on quality molded plastic parts. Quality control ensures that these components are durable, UV-resistant, and capable of withstanding daily wear and tear.

- Mobility & EVs: Electric vehicles and mobility solutions like scooters and e-bikes require high-performance components that reduce weight while maintaining strength. Quality control processes help ensure parts like battery enclosures and frame components meet the required durability and safety standards.

Also Read: Exploring India’s Leading Auto Parts Manufacturers in Key Locations

Achieving such precision begins with a deeper understanding of the materials used in the molding process.

5 Key Factors in Plastic Material Selection that Injection Molding Engineers Must Consider

Selecting the right plastic material for injection molding is critical to the success of the manufacturing process and the functionality of the final product. The material must meet the demands of the specific application, taking into account the following factors:

- Mechanical Properties: The material must have sufficient strength to handle the mechanical stresses it will face in its application. Automotive components like bumpers and dashboards require materials with high tensile strength and impact resistance.

- Thermal Resistance: Certain industries, like automotive and aerospace, require materials that can withstand high temperatures without deforming or losing strength. Plastics with high thermal resistance are crucial for engine components and parts exposed to hot environments.

- Chemical Resistance: Materials must be resistant to chemicals, oils, and other substances they may come into contact with. For example, parts used in fuel systems must be made of plastic that resists fuel degradation and corrosion.

- Moldability and Design Flexibility: Materials should be easy to mold into the desired shape without losing performance or requiring excessive amounts of time and energy. This flexibility is particularly important in industries like automotive and consumer goods, where part complexity is often high.

- Cost and Availability: The chosen material must also be cost-effective and readily available. Automotive manufacturers, for example, often need high-volume production runs of parts like bumpers, which require low-cost, widely available materials.

Once the right material is chosen, the next step is to ensure every stage of inspection aligns with design and performance goals.

5 Stages of Quality Control Inspection in Plastic Injection Molding

Injection molding quality control is an ongoing process that involves several stages of inspection to ensure parts meet the required specifications. These stages include:

Pre-production Inspection

Before production begins, manufacturers conduct tests on raw materials to ensure they meet the required specifications. This step is crucial to avoid issues during the molding process.

In-Process Monitoring

During the molding process, critical parameters such as temperature, pressure, and injection speed are monitored. These factors influence the final product’s quality, and deviations can lead to defects like warping or incomplete parts.

Post-production Inspection

After parts are molded, they undergo detailed inspections to assess visual quality, dimensions, and functionality. Tools like coordinate measuring machines (CMM) are often used to verify that parts meet the precise specifications.

Sampling and Statistical Control

Sampling techniques, such as Statistical Process Control (SPC), help monitor production trends and detect any deviations in the quality of the final parts. SPC allows manufacturers to make adjustments before defects affect the entire production run.

Final Inspection and Packaging

Once the parts pass the quality control checks, they undergo final inspection before being packaged and shipped. The final checks ensure the parts are free from defects and meet all the necessary regulatory standards.

Also Read: Vehicle Handbrake Lever Manufacturer and Exporters – Quality, Precision & Performance

To support these inspections, manufacturers rely on advanced tools and analytical techniques.

Tools and Techniques Used by Injection Molding Manufacturers

Manufacturers rely on various tools and techniques to ensure quality control in injection molding. These methods help detect defects early in the process and ensure that every part meets the required specifications.

- Coordinate Measuring Machines (CMM): These devices are used to measure the physical dimensions of parts with high accuracy, ensuring that the components are produced within the tight tolerances required for automotive, aerospace, and other high-precision industries.

- Visual Inspection Systems: Automated visual inspection systems use high-resolution cameras and software to identify defects such as cracks, discoloration, or incorrect moldings. This technology is essential for detecting surface flaws that could affect the part’s functionality or appearance.

- Infrared Thermography: This technique is used to monitor the temperature of the mold and the plastic material during the molding process. Uneven temperature distribution can lead to defects, so infrared thermography helps ensure uniformity.

- Plastic Flow Analysis Software: This software simulates how molten plastic flows into the mold cavity, helping manufacturers optimize injection parameters and reduce defects caused by air entrapment or poor mold filling.

- Optical Profilometers: These devices measure the surface profile of parts, ensuring they meet the required finish and texture specifications. This is particularly important for parts where appearance is critical, such as automotive exterior components.

Despite these measures, manufacturers must remain vigilant about common production defects.

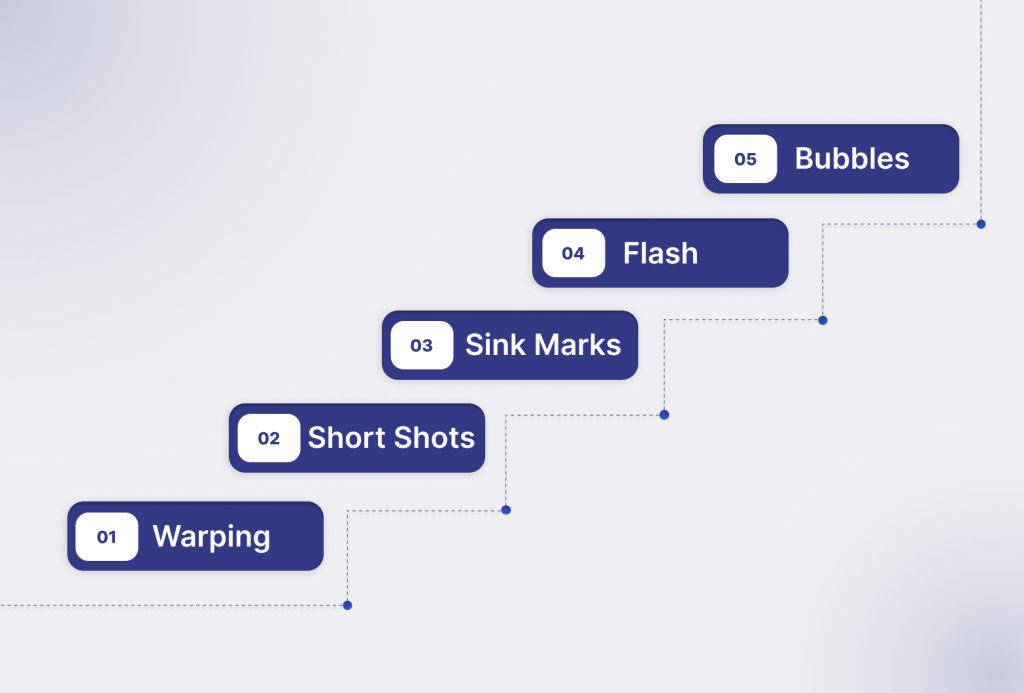

Common Injection Molding Defects Plastic Manufacturers Should Look Out For

Despite careful planning and quality control, defects can still occur during the injection molding process. The main types of defects include:

- Warping: Warping occurs when the molded part cools unevenly, causing it to distort. This can happen if cooling times are too long or too short, or if mold temperatures are inconsistent.

- Short Shots: Short shots happen when the mold cavity is not completely filled, resulting in incomplete parts. This can be caused by insufficient injection pressure, improper material flow, or blocked injection nozzles.

- Sink Marks: Sink marks are depressions that appear on the surface of the part, typically caused by improper packing pressure or uneven cooling. This defect is commonly seen in thicker sections of the molded part.

- Flash: Flash refers to the excess material that leaks out of the mold, usually due to high injection pressure or improper mold clamping. It can create visible lines and lead to product quality issues.

- Bubbles and Voids: Trapped air or gas can form bubbles or voids within the part, which affects its strength and integrity. This can be caused by improper venting or incorrect molding parameters.

Also Read: What is Plastic Welding?

That’s why defining the right process parameters becomes critical in maintaining uniform quality.

Critical Quality Control Parameters in Injection Molding Followed by Plastic Manufacturers

Quality control parameters in injection molding must be closely monitored to ensure that the final product meets all specifications. Key parameters include:

- Injection Pressure: The amount of pressure applied during injection is critical to filling the mold cavity completely and uniformly. Too little pressure can result in short shots, while too much pressure can cause flash.

- Mold Temperature: Consistent mold temperature ensures that the plastic flows properly and cools evenly. Temperature fluctuations can lead to warping or other defects in the final product.

- Injection Speed: The speed at which the plastic is injected into the mold cavity can affect the part’s quality. High speeds may cause air entrapment, while low speeds can lead to incomplete filling of the mold.

- Cooling Time: The cooling time needed for the plastic to solidify and take shape is crucial. If the part is removed from the mold too soon, it may warp or deform.

- Cycle Time: Optimizing cycle time helps reduce production costs without compromising quality. Shorter cycles can increase productivity, but must be balanced with the need for adequate cooling and curing.

Alongside these, manufacturers apply structured quality control methodologies to standardize excellence.

Methods of Quality Control Processes for Plastic Manufacturers

Several quality control methodologies can help manufacturers maintain high-quality standards in injection molding. These methods include:

- Total Quality Management (TQM): A company-wide approach to continuous improvement in all aspects of production, ensuring that quality is built into every stage of the process.

- Computer-Aided Quality (CAQ): CAQ systems use advanced software tools to monitor and control the quality of the injection molding process in real-time, ensuring that each part meets the required specifications.

- Advanced Quality Planning (AQP): A proactive approach to quality management that involves identifying potential quality issues during the product design phase, ensuring that solutions are implemented before production begins.

- Statistical Process Control (SPC): This method uses statistical data to monitor and control the injection molding process, helping manufacturers maintain consistent quality and reduce variability.

- Continuous Process Control (CPC): CPC focuses on maintaining stability in the production process by continuously monitoring key parameters and making adjustments as needed.

- Totally Integrated Automation (TIA): TIA integrates quality control systems with automated production processes, enhancing efficiency and reducing the risk of human error.

Also Read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

Maintaining molds themselves also plays a key role in ensuring consistent quality across production cycles.

Best Practices for Preventive Mold Maintenance in Manufacturing

Preventive maintenance of molds is important to maintaining consistent part quality and preventing production delays due to mold failures. The following best practices reduce the need for costly replacements or repairs, ultimately improving production efficiency and reducing downtime:

Regular calibration of inspection equipment

Calibration of inspection equipment ensures that measurements are accurate and consistent throughout the production process. This reduces the risk of incorrect measurements leading to product defects and ensures compliance with quality standards.

Automated inspection systems

Automated systems improve the accuracy and speed of quality inspections, minimizing human error. These systems use high-tech cameras and sensors to detect defects such as surface imperfections, cracks, or inconsistencies in the mold, ensuring timely identification of issues before they affect production.

Sampling techniques

Sampling techniques, such as taking random samples from a batch, allow manufacturers to assess the overall quality of a production run without inspecting every single part. This helps in efficiently identifying defects while keeping production costs low.

Thorough documentation of inspection results

Documenting inspection results provides valuable data that can be used for trend analysis and continuous improvement. By tracking inspection results over time, manufacturers can identify recurring issues and implement corrective actions to improve product quality.

Training employees

Proper employee training is essential to maintaining consistent quality standards. By educating staff on defect identification and quality control techniques, manufacturers ensure that their team can quickly address issues, minimizing the risk of defects and ensuring higher quality consistency across production runs.

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

For manufacturers seeking consistent precision, partnering with an experienced injection molding expert is essential.

Partner with the Right High-Quality Injection Molding Experts

Effective quality control is essential for producing precision-engineered components that meet industry standards and customer expectations. In injection molding, the smallest error can lead to costly defects, making quality control crucial for manufacturers.

Jairaj Group has over 35 years of experience specializing in delivering high-quality plastic components for automotive, aerospace, defense, and industrial applications. Our advanced molding technologies ensure that every part meets stringent quality requirements, from the first step in production to the final inspection.

- Plastic Bellows & Struts: Jairaj Group’s plastic bellows and struts, made for automotive and heavy-duty vehicles, are manufactured using advanced injection molding techniques, ensuring superior flexibility, durability, and resistance to extreme conditions.

- Brake & Accelerator Pedals: Our brake and accelerator pedals, produced with precision injection molding, offer exceptional impact resistance and strength, meeting stringent safety standards for automotive and two-wheeler applications.

- Shockers & Suspension Components: Jairaj Group’s shockers and suspension components are designed to absorb vibrations and impact, manufactured from high-performance materials like Nylon 6/66 and Polypropylene (PPCP) using cutting-edge molding technology.

- Braking System Components: Manufactured with precision and reliability, our braking system components for automotive, two-wheelers, and heavy-duty vehicles use ABS and PBT Arnite, ensuring high performance and safety in demanding environments.

- Precision Components from Advanced Polymers: We specialize in precision components, such as bumper caps and engine assemblies, utilizing high-strength polymers like Nylon 6/66 and PBT to ensure durability and optimal performance for automotive and aerospace applications.

- Roto Moulding Components: Our roto moulding components cater to industries like defense and aerospace, offering flexibility and strength with advanced polymers like PA 12 and Polycarbonate, ensuring parts meet high-performance standards.

With state-of-the-art manufacturing facilities in Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand, Jairaj Group uses advanced technologies such as injection molding, blow molding, and rotational molding to ensure precise quality control. From injection molding quality control to custom product design, we guarantee that every part meets the highest standards for durability and performance.

Conclusion

By focusing on key quality parameters, adopting modern methodologies, and using advanced tools, manufacturers can reduce defects, improve production efficiency, and enhance product reliability. The ongoing advancement of materials, processes, and technologies will continue to drive the success of quality control in injection molding, ensuring high-quality, precision-engineered plastic components across industries.

At Jairaj Group, our Shock Absorber Covers, Inner Trims, and Display Housings are produced using ABS+PC and Polycarbonate blends that demand precise control of flow and cooling rates. Through advanced injection molding and automated inspection systems, we detect deviations in wall thickness, sink marks, and weld lines in real time. Using Mold Development and in-mold temperature regulation, we maintain dimensional accuracy and surface finish, ensuring consistent quality for high-performance automotive assemblies.

Contact Jairaj Group today to discover how our precision plastic injection molding solutions can optimize your production processes.

FAQs

1. What materials are most commonly used in injection molding?

Polypropylene, ABS, and polyurethane are common materials due to their durability, moldability, and cost-effectiveness.

2. How does quality control prevent defects in injection molding?

By monitoring key parameters such as pressure, temperature, and speed, manufacturers can detect deviations early, preventing defects like warping or short shots.

3. Why is mold maintenance important for quality control?

Regular mold maintenance ensures that molds function efficiently, preventing defects caused by mold wear or contamination.

4. What role does statistical process control play in injection molding?

SPC uses statistical data to monitor and control the molding process, helping maintain consistency and reduce variability in the final product.

5. How can automated inspection improve quality control?

Automated inspection systems reduce human error, increase speed, and ensure consistent quality in parts by providing real-time analysis.

6. What is Total Quality Management (TQM) in injection molding?

TQM is a company-wide approach to continuous improvement, ensuring that every stage of production meets high-quality standards.