Component supply instability coupled with technical non-compliance presents a primary risk to production linearity and brand integrity. This is compounded by the increasing value-add required for new mobility platforms. Sourcing decisions must prioritise partners capable of mitigating these vulnerabilities.

The Indian auto component sector is strategically positioned to address this requirement, with the industry clocking a turnover of ₹6.73 lakh crore in FY 24-25. This growth is driven by demand for high-specification parts and global supply chain diversification.

This blog identifies the top 10 suppliers of automotive components in 2025. Effective sourcing demands a precise assessment of supplier adherence to IATF standards, engineering capacity, and future-ready product portfolios.

Key Takeaways

- Industry Focus: Innovation is driven by new mobility needs. Component suppliers are now focused on lightweighting, EV-specific parts, and advanced electronics for safety.

- Supplier Landscape: The blog profiles the top 10 automotive component suppliers in India, detailing their established expertise in areas like metal forming, specialised forgings, and polymer systems.

- Strategic Sourcing: Sourcing decisions must prioritise partners that demonstrate IATF compliance, robust engineering capacity, and a future-ready product portfolio to mitigate technical risk.

- Supplier Selection: Several factors guide partner choice, including technological capabilities, scalability, material expertise, and verifiable financial stability.

Essential Components Driving India’s Automotive Demand

The demand for automotive components in India is intensifying due to two fundamental shifts: stringent regulatory mandates and the monumental industry pivot toward electric mobility. Component suppliers are now the primary drivers of innovation, focusing on parts that improve safety, reduce emissions, and increase vehicle efficiency, rather than merely supplying traditional mechanical parts.

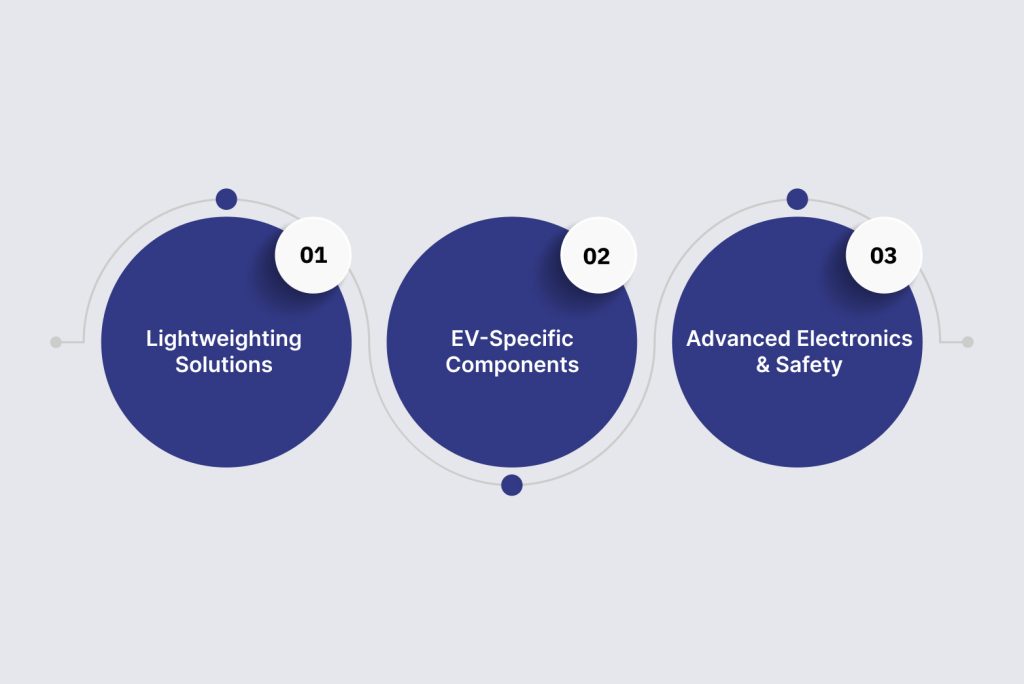

The most strategic components commanding supplier attention today fall under these three critical areas:

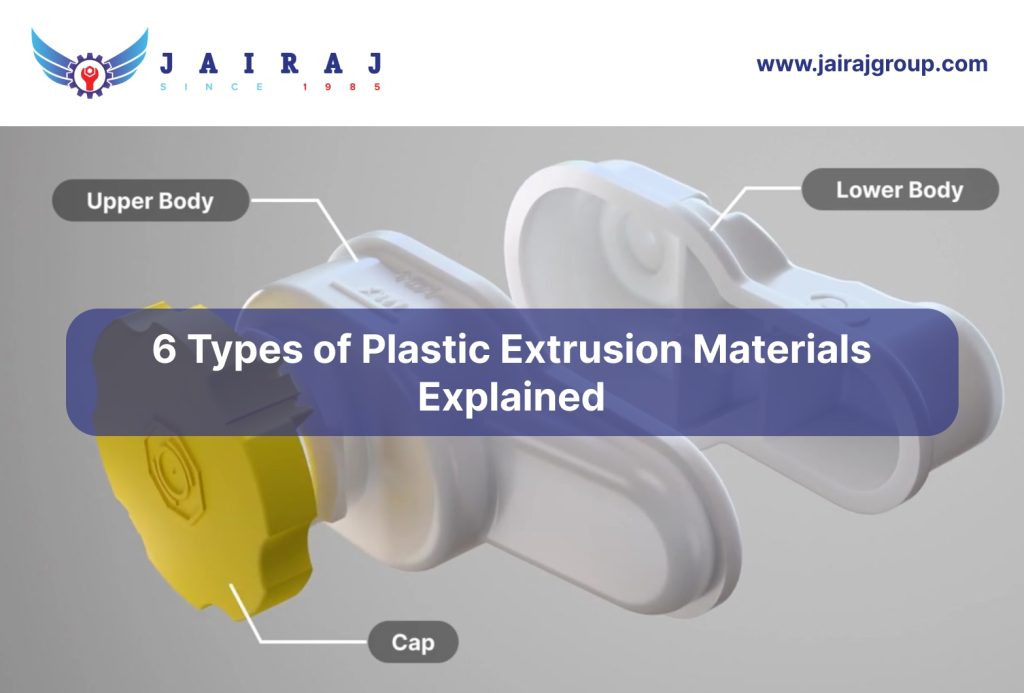

- Lightweighting Solutions: Advanced polymers, speciality plastics, and high-strength, low-density alloys necessary to meet strict emission norms and improve fuel efficiency.

- EV-Specific Components (E-Mobility): Parts directly related to the electric powertrain, including battery housings, thermal management components, specialised wiring harnesses, and charging infrastructure hardware.

- Advanced Electronics & Safety: Sensors, controllers, ADAS (Advanced Driver-Assistance Systems) hardware, and intricate electronic assemblies that enable connected and safer vehicles.

With these critical components defining the future of mobility, it is essential to identify the key players capable of delivering them.

Also Read: 7 Common Types of Plastics Used in Automotive Components

Top 10 Suppliers of Automotive Components in India

The leading suppliers of automotive parts differentiate themselves not merely by revenue volume but by their verified technological alignment with global mobility shifts. Here are the top 10 automotive component suppliers defined by their capacity for strategic value addition in complex manufacturing environments:

1. Jairaj Group

Jairaj Group is an experienced precision component manufacturer focused on complex plastic, sheet metal, and hybrid assemblies across five strategic Indian manufacturing clusters. For over 35 years, the company has delivered components requiring high technical compliance for both automotive and demanding non-automotive sectors.

- Established: 1985

- Headquarters: Faridabad, Haryana, India

- Certifications: IATF 16949, ISO 9001/14001, CE

- Industries Served: Automotive, Mobility & EVs, Defence, Aerospace, and Railways

Core Technical Capabilities

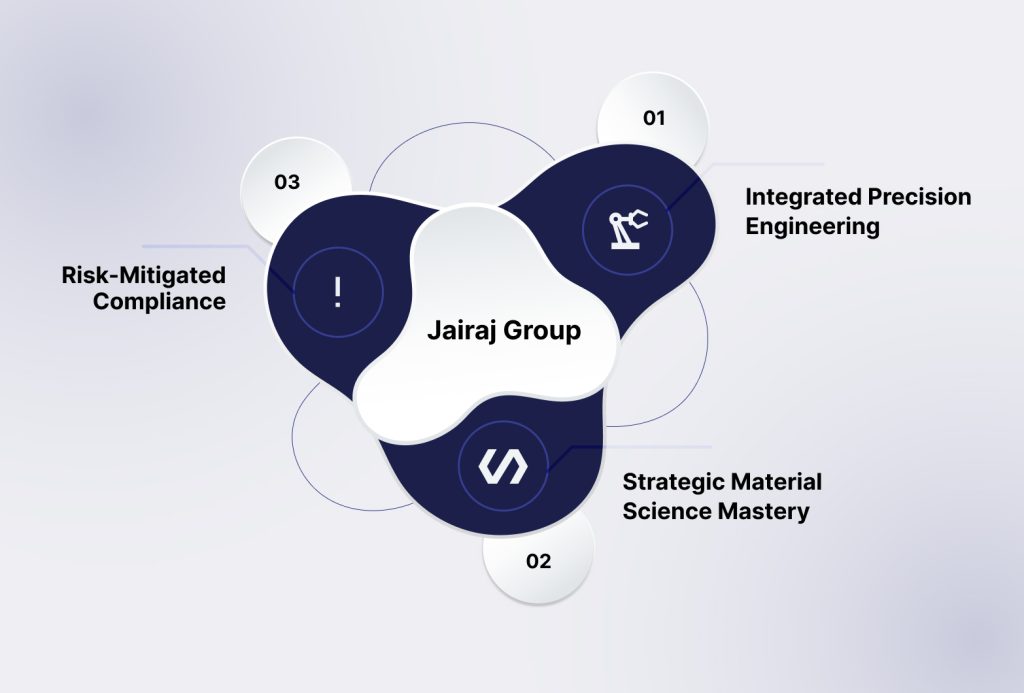

- Integrated Precision Engineering: Combines comprehensive moulding technologies (injection, blow, rotational) with in-house tooling to guarantee dimensional accuracy and component integrity across high-volume, complex assemblies.

- Strategic Material Science Mastery: Expertise in advanced polymers (PP, ABS, Nylons, high-performance composites) ensures component lightweighting, superior durability, and cost-effectiveness tailored to stringent regulatory standards.

- Risk-Mitigated Compliance & Support: Validated quality through IATF 16949 certification, backed by a cross-sector track record (aerospace/defence), offering a complete R&D and full lifecycle support partnership.

Key Product Focus

Why Choose Jairaj Group?

Jairaj Group stands out by integrating material science expertise with rigorous quality control, providing OEM and Tier-1 clients with reduced technical risk and assured component integrity. This unique blend of advanced technology and multi-sector compliance positions them as a highly reliable source for critical, high-tolerance components.

2. Bosch

Bosch is a leading global supplier of technology and services, with one of its largest business sectors being Mobility Solutions. It is considered the world’s largest automotive supplier.

In India, Bosch Limited is the flagship company, playing a crucial role in providing innovative hardware, software, and services for various vehicle segments, focusing on connected, automated, and electrified mobility.

- Established: 1886 (global); 1951 (Manufacturing in India)

- Headquarters: Bengaluru, Karnataka (Bosch Limited)

- Speciality: Dominates the aftermarket with the largest product range under one brand in India, supported by comprehensive workshop concepts.

- Key Products: Fuel injection systems, braking systems (ABS, ESP), automotive electronics (ECUs), driver assistance systems, starters, alternators, sensors, and spark plugs.

- Industries Served: Mobility (Automotive), Industrial Technology, Consumer Goods, Energy and Building Technology.

Also Read: Polypropylene vs ABS: Choosing the Right Plastic

3. Samvardhana Motherson International Ltd (SMIL)

Samvardhana Motherson Group is one of the world’s largest and fastest-growing global manufacturers of automotive components, operating as a full system solutions provider. It is highly diversified, supplying a broad portfolio of components for interior, exterior, and electrical systems to major global automotive OEMs.

- Established: 1986

- Headquarters: Noida, Uttar Pradesh

- Speciality: A specialised Tier-1 supplier for highly integrated, complex modules like cockpits and rear-view mirror systems developed through global acquisitions.

- Key Products: Wiring harnesses (electrical distribution systems), rearview mirrors, moulded plastic parts (bumpers, dashboards, interior/exterior trims), camera systems, lighting systems, and cockpits.

- Industries Served: Automotive, Aerospace, Health & Medical, Logistics.

4. JBM Group

JBM Group is an Indian conglomerate with a significant and growing presence in the automotive sector, offering end-to-end “art to part” solutions for auto components and systems. The group is heavily invested in future mobility, particularly as a key player in the Electric Vehicle (EV) ecosystem and the largest electric bus manufacturer in the country.

- Established: 1983

- Headquarters: Gurgaon, Haryana

- Speciality: India’s largest player in the specialised field of metal forming systems and critical skin panels for vehicle bodies.

- Key Products: Sheet metal components and assemblies, chassis and suspension systems, exhaust systems, press tools/dies, EV aggregates, and electric buses.

- Industries Served: Automotive, Engineering & Design Services, Renewables (Solar), Logistics, Railways.

5. Uno Minda Limited

A leading global manufacturer and supplier of innovative automotive components and systems for OEMs, catering to passenger cars, commercial vehicles, and two- and three-wheelers (ICE and EV/hybrid). The group operates 75 manufacturing facilities and 37 R&D/engineering centres across multiple countries.

- Established: 1958

- Headquarters: New Delhi-NCR

- Speciality: Accelerates innovation by utilising 19 strategic joint ventures and technical collaborations with global manufacturers.

- Key Products: Automotive Switching Systems, Automotive Lighting Systems (headlamps, rear lamps), Automotive Acoustic Systems (horns, speakers), Seating Systems, and Alloy Wheels.

- Industries Served: Automotive, Aftermarket

Also Read: Automotive Injection Molding Guide for Cost Optimization and Supplier Strategy

6. Endurance Technologies Ltd

A major auto component manufacturer with a global footprint, recognised as the largest aluminium die-casting company in India and the largest two- and three-wheeler auto component manufacturer in the country. They provide end-to-end solutions from design to aftermarket service.

- Established: 1985

- Headquarters: Aurangabad, Maharashtra

- Speciality: Core expertise lies in advanced pressure and gravity aluminium die-casting for complex engine and transmission components

- Key Products: Aluminium Die-Casting (raw and machined), Suspension Products, Transmission Components, and Braking Systems.

- Industries Served: Automotive, Non-Automotive Industrial Applications.

7. Varroc Engineering Ltd

A global auto technology solution company that designs, develops, and manufactures electrical, electronics, lighting, polymer, and metallic solutions for OEMs across all vehicle segments, including a strong focus on future mobility and aftermarket services.

- Established: 1990

- Headquarters: Aurangabad, Maharashtra

- Speciality: Provides full system solutions by integrating electrical, electronics, and lighting systems with smart mobility features like ADAS.

- Key Products: Exterior Lighting Systems, Powertrain Components, Electrical & Electronics, Polymer Body Parts, and Metallics.

- Industries Served: Automotive, Consumer Durables, and Aftermarket.

8. Bharat Forge Limited

Bharat Forge is the flagship company of the Kalyani Group and one of the world’s largest forging companies. It has transformed from an India-focused auto component supplier into a global engineering firm that manufactures high-performance, critical, and safety components across a wide range of industrial sectors.

- Established: 1961

- Headquarters: Pune, Maharashtra

- Speciality: Expertise in metallurgy and metal forming to produce critical powertrain and chassis safety components for both automotive and non-automotive heavy industries.

- Key Products: Forged Components (Crankshafts, Axles, Connecting Rods, Steering Knuckles), Powertrain & Chassis components, and critical components for industrial segments.

- Industries Served: Automotive/Mobility, Defence/Aerospace, Energy (Oil & Gas, Power), Construction & Mining, Railways, Marine.

9. Sundram Fasteners Ltd

A member of the TVS Group, Sundram Fasteners is a global leader in manufacturing critical, high-precision components. It is particularly renowned for its extensive range of high-tensile fasteners and precision-driven powertrain components, serving OEM and aftermarket customers globally.

- Established: 1966

- Headquarters: Chennai, Tamil Nadu

- Speciality: Global market leader in manufacturing High-Tensile Fasteners and precision Cold Extruded Parts for high-stress, safety-critical applications in diverse industries.

- Key Products: High Tensile Fasteners (Bolts, Nuts), Powertrain Components (Shafts, Clutch Hubs), Cold Extruded Parts (Gear Blanks, Transmission Shafts), Pumps & Assemblies (Water Pumps, Oil Pumps), and Powder Metallurgy Products.

- Industries Served: Automotive, Wind Energy, Aviation, Aerospace, Farm Equipment, and Infrastructure.

10. Jamna Auto Industries Ltd

Jamna Auto Industries (JAI) is India’s largest and a prominent global manufacturer of suspension products. The company focuses primarily on producing a wide array of leaf springs and related components for the commercial vehicle segment.

- Established: 1954 (Initial operations)

- Headquarters: New Delhi

- Speciality: The pioneering and leading manufacturer in India for all types of Commercial Vehicle Suspension Systems.

- Key Products: Multi-Leaf Springs, Parabolic Springs, Lift Axles, Trailer Suspensions (Mechanical and Air), Air Suspension, and allied components.

- Industries Served: Automotive (focused on Commercial Vehicles and Trailers), Aftermarket.

Transitioning from understanding what these suppliers offer, the next logical step is to determine how to choose the right one for your specific needs.

Also Read: How to Choose the Right Injection Molding Supplier

How to Choose the Right Automotive Component Supplier in India?

Selecting the ideal automotive component supplier directly impacts a vehicle’s final quality, safety, and cost structure. Given the industry’s shift toward EVs and advanced polymer parts, it’s crucial to evaluate a partner’s long-term capabilities and commitment to global compliance standards.

The following key factors influence supplier selection:

- Quality & Certifications: Require IATF 16949 and ISO certifications and proven quality control systems.

- Technological Capabilities: Evaluate advanced manufacturing technology (e.g., CNC, automation, in-house tool design) and R&D.

- Scalability & Capacity: Ensure the supplier can reliably handle current volume and future growth (Just-in-Time/JIT delivery).

- Material Expertise: Check for proficiency in working with specialised or lightweight materials (e.g., advanced polymers) relevant to modern vehicles.

- Supply Chain Resilience: Assess their logistics efficiency, multi-location presence, and contingency plans for disruptions.

- Financial Stability: Verify the supplier’s track record and financial health to ensure long-term partnership reliability.

- Design & Customisation: Look for an ability to offer design collaboration and value engineering inputs, not just mass production.

- Industry Reputation: Review their experience, client testimonials, and track record with major OEMs and Tier-1 partners.

Jairaj Group differentiates itself through its deep-seated expertise in high-precision polymer and plastic engineering, positioning itself as a critical player in the move toward lightweight and composite components. Their in-house tool room capabilities and proficiency in diverse processes make them a “one-stop shop” for complex plastic automotive solutions.

Conclusion

Choosing the right automotive component supplier in India is a strategic decision for mitigating risk and accelerating your time-to-market. Understanding the diverse strengths of industry giants gives you the intelligence to build a resilient, high-quality supply chain.

This knowledge allows you to move confidently from large-scale manufacturers to specialised innovators. You can ensure your supply chain is prepared for future industry demands, especially the crucial shift toward electric mobility platforms.

Get in touch with Jairaj Group to explore custom, high-precision plastic solutions that drive weight reduction and EV readiness.

FAQs

1. What is the most critical non-quality risk OEMs face when sourcing single-point components from a Tier 1 supplier?

Supplier financial health is the critical non-quality risk; poor liquidity or high debt can lead to sudden production halts and premature tooling failure.

2. What specialised material validation is essential for polymer components used in high-voltage Electric Vehicle (EV) applications?

Compliance requires testing for Dielectric Strength and Comparative Tracking Index (CTI), ensuring long-term electrical insulation and thermal stability beyond standard IATF requirements.

3. What challenge does the Indian automotive component supplier industry face today?

The shift to Electric Vehicles (EVs) demands massive, non-recoverable investment in specialised materials (HPPs), new tooling, and updated validation for thermal and electrical safety, straining capital and legacy business models.

4. How quickly can a component supplier typically scale up new EV battery-related polymer parts?

This depends on tooling complexity and material validation time. Look for suppliers who have existing, validated High-Performance Polymer (HPP) experience to cut the learning curve.

5. Beyond quality, what is a key supply chain risk that IATF 16949 aims to reduce?

The standard requires systems for Risk Management and Contingency Planning to address potential supply disruptions and prevent line shutdowns, especially for critical components.