In recent years, the use of plastic extrusion machines has risen across various sectors due to their efficiency, user-friendliness, flexibility, and ability to produce superior-quality parts.

This method is particularly valuable for creating components that can endure extreme conditions, such as UV radiation and physical wear. The global plastic extrusion machine market was valued at USD 6,408.4 million (INR 52,900 crore) in 2022, driven by the growing demand for plastic products and increased investments in construction.

If you’re manufacturing automotive parts, mobility components, military-grade polymer components, or heavy equipment, selecting the right plastic material is vital to meeting performance standards and ensuring long-term reliability.

This blog will explore the fundamentals of plastic extrusion, the key benefits it offers, and the various types of plastic extrusion materials ideal for industrial applications.

Key Takeaways

- Polyethylene offers excellent chemical and moisture resistance for outdoor and industrial applications.

- Polypropylene provides enhanced strength and heat resistance, ideal for automotive interiors.

- Polycarbonate ensures impact resistance and clarity for high-demand components like bumpers and protective covers.

- PVC excels in weathering resistance, making it ideal for pipes and automotive seals.

- Nylon offers high strength and durability, essential for brake components and fuel line connectors.

What is Plastic Extrusion?

Plastic extrusion is a process where raw plastic is melted and forced through a mold to create specific shapes. The plastic is heated, then pushed through using a screw or piston, forming continuous profiles that are cooled and cut into lengths.

Used in industries like automotive, aerospace, and construction, plastic extrusion creates high-performance parts. Materials are chosen based on requirements like durability, strength, flexibility, and resistance to environmental conditions.

If your aerospace or automotive manufacturing process struggles with inconsistent extrusion profiles or dimensional deviations in critical load-bearing components, JaiRaj Group provides precision plastic extrusion materials. Our brake & accelerator pedals and shockers & suspension components are engineered for exact tolerances, superior strength, and reliable performance in demanding aerospace, defense, and industrial applications.

Plastic extrusion provides several benefits, making it an ideal manufacturing process for various industries. Here are the key advantages:

- Long-Length Production: The ability to produce continuous plastic profiles reduces the need for additional parts or joints, streamlining production processes.

- Material Versatility: Various plastic extrusion materials offer durability, flexibility, and cost-effectiveness for applications in industries like automotive, mobility, and defense.

- Precise Material Control: The extrusion process allows precise control over material thickness, ensuring high-quality output with minimal waste.

- Scalability: Plastic extrusion can efficiently handle both small and large production volumes, making it a versatile solution for manufacturers with fluctuating demand.

- Customizability: The process allows the incorporation of additives such as UV resistance, fire retardance, and chemical resistance, making it ideal for high-performance components in automotive and heavy equipment industries.

Next, let’s explore the different types of plastic extrusion materials used to create components for high-performance applications.

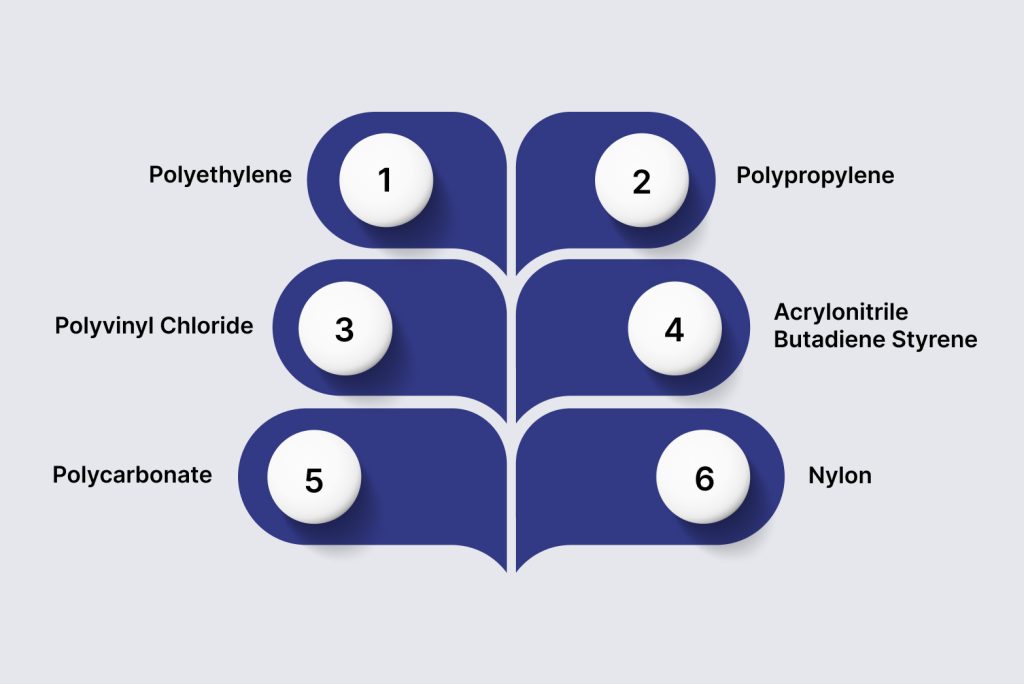

6 Types of Plastic Extrusion Materials

The selection of plastic extrusion materials is crucial, as the material properties directly impact the performance, durability, and cost of the final product. Here are some of the most commonly used materials in plastic extrusion:

1. Polyethylene (PE)

Widely used in applications that require chemical resistance and flexibility, PE is ideal for pipes, tubing, and seals used in the automotive, construction, and packaging industries.

2. Polypropylene (PP)

PP is known for its strength, chemical resistance, and lightweight properties. It’s commonly used for automotive parts, industrial containers, and consumer goods components.

3. Polyvinyl Chloride (PVC)

PVC is one of the most versatile and durable plastics, widely used in pipe systems, electrical wiring, and window profiles in construction and industrial applications.

4. Acrylonitrile Butadiene Styrene (ABS)

ABS is commonly used for creating durable, impact-resistant components, such as interior panels, dashboards, and bumpers in automotive manufacturing.

5. Polycarbonate (PC)

Known for its excellent impact resistance and optical clarity, PC is used in automotive lighting, windshields, and protective covers for industrial equipment.

6. Nylon (PA)

Nylon offers superior strength, wear resistance, and flexibility, making it ideal for automotive parts like brake components, gears, and electrical connectors.

Also Read: Top 10 Auto Parts Manufacturers in India

Now, it’s essential to explore the applications for plastic extrusion in various manufacturing sectors to understand its full potential.

Applications for Plastic Extrusion

Plastic extrusion is used in a wide range of applications across several industries. Some of the most common applications include:

- Automotive: Plastic extrusion materials are used to create trim pieces, seals, weather strips, and interior components. These parts offer durability and flexibility, essential for automotive manufacturing.

- Construction and Infrastructure: Plastic pipes, tubing, and profiles are commonly extruded for use in plumbing, electrical, and structural applications, offering strength and resistance to environmental stressors.

- Packaging: Plastic films, sheets, and tubes used in packaging are commonly extruded, providing flexibility, strength, and lightweight properties that are vital for the packaging industry.

- Aerospace: Plastic extrusion materials are used in the production of components such as ducts, panels, and insulation, where lightweight and high-performance qualities are critical.

- Mobility & EVs: Extruded plastic components are also essential for electric vehicles and scooters, including parts like cables, housing, and internal components that must meet specific safety and durability standards.

Next, let’s look into the different types of plastic extrusion and how each offers unique benefits for specialized manufacturing needs.

Types of Plastic Extrusion for Manufacturing Efficiency

There are various methods of plastic extrusion, each suited to specific types of components and production volumes. The most common types include:

1. Profile Extrusion

This type of extrusion is used to create continuous shapes with a fixed cross-section, such as seals, weatherstripping, and trim pieces for automotive and construction applications.

2. Sheet Extrusion

In sheet extrusion, plastics are formed into large sheets or films, which are then used in packaging, construction materials, and automotive panels.

3. Pipe and Tube Extrusion

This process is used to create cylindrical products like plastic pipes, tubing, and hoses, essential in plumbing, automotive, and industrial equipment sectors.

4. Film Extrusion

Plastic films are created for packaging, agriculture, and construction industries, offering flexibility and strength for lightweight applications.

5. Blown Film Extrusion

This process is commonly used for creating plastic bags, stretch films, and other flexible plastic products, offering high efficiency and minimal waste.

Also Read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

Next, let’s examine plastic extruder components and their impact on precision engineering in industries like defense and aerospace.

5 Plastic Extruder Components and Their Impact on Precision Engineering

The plastic extruder itself is composed of several key components that work together to ensure the extrusion process is efficient and precise. These components include:

- Feed Hopper: The feed hopper is where the extruder receives raw plastic material, typically in the form of pellets or granules. It guarantees a constant and reliable material flow into the extrusion process.

- Screw and Barrel: The screw inside the barrel rotates, applying pressure and heat to the plastic, causing it to melt and flow. The barrel provides the heat required to soften the plastic, preparing it for shaping.

- Die: The die is a precisely designed tool that shapes the melted plastic into a specific profile. It defines the final shape and size of the extruded product, whether it’s a pipe, sheet, or custom profile.

- Cooling System: Once the plastic has been extruded through the die, it enters the cooling system, where it is rapidly cooled by air or water.

- Puller and Cutter: After the plastic has been cooled, the puller draws the material through the extruder at a consistent rate. The cutter then cuts the material into the desired length, completing the extrusion process.

Now, let’s explore the types of plastic extruders and their specific applications in OEM and heavy-duty equipment manufacturing.

Types of Plastic Extruders and Their Applications for OEMs and Heavy-Duty Equipment Manufacturers

There are several types of plastic extruders, each designed to meet specific manufacturing needs:

1. Single-Screw Extruder

The most common type of extruder, used for simple applications where uniformity and consistency are crucial. It’s often used in pipe production, sheet extrusion, and film manufacturing.

2. Twin-Screw Extruder

These extruders are typically used for more complex formulations, including mixing and compounding. They are ideal for PVC, PE, and PA blends in automotive and heavy equipment components.

3. Ram Extruder

Used for applications requiring large, complex shapes, the ram extruder works well for producing high-viscosity plastics like rubbers and thermosets.

4. Multi-Screw Extruder

This type uses multiple screws to extrude multiple materials simultaneously, offering high throughput and is ideal for producing products in large volumes with multiple layers.

Also Read: Automotive Interior & Exterior Plastic Parts Manufacturing: Trends and Innovations in 2025

Now, let’s explore the plastic extrusion process for complex manufacturing applications across industries.

Plastic Extrusion Process for Complex Manufacturing Applications

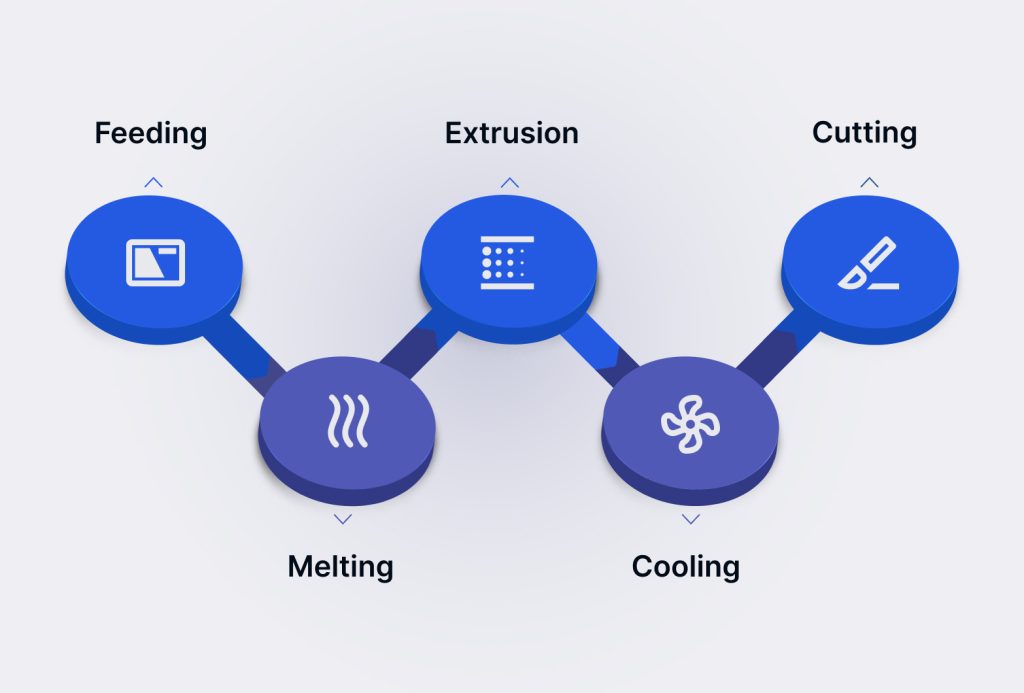

The plastic extrusion process is a continuous method of manufacturing plastic parts by melting raw plastic and forcing it through a die to form a specific shape. The process involves several key stages:

- Feeding: The extruder hopper is where the raw plastic material, which is typically in the form of pellets or granules, is loaded before starting its journey through the system.

- Melting: Inside the extruder barrel, the plastic is heated to its melting point using a combination of mechanical and thermal energy, making it ready for shaping.

- Extrusion: After being pushed through a die, the molten plastic assumes a continuous profile shape that corresponds to the application’s specifications.

- Cooling: As the extruded plastic exits the die, it is cooled using either air or water, solidifying the material into its final form while maintaining the desired properties.

- Cutting: The plastic is cut into predefined lengths or sizes in accordance with the project specifications after it has cooled and solidified.

Once you understand the plastic extrusion process, it’s crucial to evaluate and select the right materials that align with your specific manufacturing needs.

Choosing the Best Plastic Extrusion Materials for Your Manufacturing Needs

Selecting the right plastic extrusion materials is crucial for manufacturers in sectors like automotive, defense, mobility, and heavy equipment. Jairaj Group specializes in providing precision-engineered solutions for a wide range of industries. Operating from advanced facilities in Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand, we offer high-quality plastic components.

Why choose Jairaj Group?

- Advanced Molding Technologies: We utilize injection molding, blow molding, rotational molding, and extrusion molding to produce high-quality components for automotive, mobility, heavy-duty vehicles, and aerospace.

- Broad Product Offering: We provide a wide range of products, such as plastic bellows and struts, shockers and suspension parts, mobility plastic seating solutions, brake and accelerator pedals, interior and exterior accessories, and precision parts made of cutting-edge polymers.

- High-Performance Materials: We use materials such as polycarbonate, PA 12, and Nylon to ensure components like fuel connectors, bumpers, and automotive parts meet the strictest industry demands for strength and reliability.

- Customization and Expertise: With expertise in advanced polymers like PBT Arnite and TPU, we provide tailored solutions for earth movers, railways, automotive interiors, and mobility components, ensuring precise tolerances for functional and aesthetic needs.

- Compliance and Quality: Adhering to ISO, IATF, and CE certifications, we guarantee that all our products, be it for defense, solar applications, or automotive parts, comply with international quality, environmental, and safety standards.

With over 35 years of expertise, Jairaj Group provides components that meet and exceed expectations, ensuring performance in harsh environments in various industries, including automotive, defense, and industrial sectors.

Conclusion

The right plastic extrusion materials ensure that parts withstand harsh environmental conditions, improving product lifespan and reducing maintenance costs. Understanding the types of plastics, extrusion methods, and the overall process can help you select the right materials and technologies for your manufacturing needs.

Partnering with the right supplier for plastic extrusion materials offers these key benefits:

- Enhanced performance with advanced polymers like polycarbonate and polyethylene, ensuring strength and reliability in tough environments.

- Increased flexibility using materials like polypropylene and PVC, ideal for complex shapes and profiles.

- Higher efficiency with optimized processes, reducing waste and maximizing output for precise, high-quality components.

A reliable injection molding or extrusion supplier, like Jairaj Group, ensures access to advanced plastic extrusion technologies and high-quality materials tailored to your industry’s specific requirements. Jairaj Group offers precision-engineered solutions for automotive, mobility, defense, and aerospace, providing the durability and performance you need.

Contact Jairaj Group today to discover how we can help you select the perfect plastic extrusion materials for your outdoor applications.

FAQs

1. What are the advantages of outdoor applications for polyethylene (PE)?

For uses like pipes, storage containers, and automobile parts, polyethylene is perfect because of its exceptional UV stability, chemical resistance, and moisture resistance.

2. How does polypropylene (PP) compare to polyethylene for industrial use?

Polypropylene is stronger and more resistant to heat than polyethylene, making it suitable for demanding applications such as automotive interiors and industrial containers.

3. Why is polycarbonate (PC) preferred for high-impact applications?

Polycarbonate is perfect for automotive bumpers, protective covers, and aerospace components that need to be transparent and long-lasting because of its exceptional impact resistance.

4. What are the advantages of using PVC in industrial applications?

PVC is versatile, offering excellent resistance to chemicals and weathering, making it ideal for pipes, electrical conduits, and automotive seals exposed to harsh conditions.

5. What makes nylon (PA) a popular choice for automotive parts?

Nylon offers high strength, wear resistance, and thermal stability, making it ideal for automotive gears, brake components, and fuel line connectors that endure high stresses.

6. How do advanced polymers like TPU and PEEK improve performance in specialized industries?

TPU and PEEK offer superior flexibility, wear resistance, and chemical stability, making them ideal for defense and aerospace applications requiring durable, high-performance materials.