In the aerospace industry, aerospace plastics are integral for creating lightweight, durable, and high-performance components that meet the stringent requirements of modern aircraft. As advancements in materials and manufacturing processes continue, aerospace plastics are supporting a growing range of applications, from interior components to critical systems that require high strength-to-weight ratios.

With the global aerospace plastics market projected to grow from USD 26.10 billion (INR 2,29,000 crore) in 2025 to USD 483.29 billion (INR 42,40,000 crore) by 2034, this expanding market reflects the increasing demand for these materials in the aerospace sector.

This blog will explore the types of aerospace plastics used in manufacturing, the techniques employed to produce them, and their key applications across various aerospace sectors.

Key Takeaways

- Polycarbonate is used for impact-resistant aerospace windows and canopies, offering excellent clarity and strength.

- PEEK is ideal for high-performance aerospace components like seals and engine parts due to its heat resistance and durability.

- Polyimide provides exceptional thermal resistance and electrical stability, making it essential for aerospace wiring and insulation.

- ABS is commonly used in aerospace interiors for its impact resistance and design flexibility.

- Epoxy resins are key in making aerospace composites that are strong, durable, and resistant to heat and chemicals.

6 Plastic Materials Commonly Found in Aerospace Manufacturing

A wide variety of plastics are used in aerospace manufacturing, each offering specific benefits suited to different components and applications. The most commonly used plastics in the aerospace industry are:

1. Polycarbonate (PC)

Polycarbonate is a transparent, high-impact resistant plastic, often chosen for its durability and optical clarity. It performs well under extreme temperatures and stress, making it ideal for aerospace components.

Application:

Polycarbonate is commonly used in aerospace for cockpit windows, light covers, and lenses due to its ability to withstand high stress and provide clarity in critical visibility areas.

2. Polyetheretherketone (PEEK)

PEEK is a high-performance plastic known for its excellent mechanical strength, high heat resistance, and chemical durability. It’s widely used for parts that require strength under extreme conditions.

Application:

PEEK is used in aerospace for engine components, structural elements, and seals due to its exceptional resistance to wear, chemicals, and high temperatures, ensuring durability and reliability in critical applications.

3. Polyimide (PI)

Polyimide is a high-performance plastic known for its thermal stability and low flammability. It’s frequently used in high-temperature environments and electronic components where resistance to heat is crucial.

Application:

Polyimide is used for wires, cables, and insulation in aerospace, providing essential heat resistance in electronic components and systems that operate at elevated temperatures.

4. Acrylonitrile Butadiene Styrene (ABS)

ABS is a tough, cost-effective plastic valued for its impact resistance and flexibility. It provides a balance of strength and aesthetic appeal, making it ideal for visible interior components.

Application:

ABS is commonly used in aerospace for interior components like dashboards, cabinets, and furniture, where both strength and appearance are important, offering reliability and a polished look.

5. Polyamide (PA or Nylon)

Nylon is a versatile, durable plastic known for its wear resistance and low friction. It’s used in aerospace components that require strength and flexibility under dynamic loads.

Application:

Nylon is often found in gears, bearings, and aircraft components, providing high wear resistance and low friction to enhance performance and extend the life of these mechanical parts.

6. Epoxy Resins

Epoxy resins are commonly used in aerospace for their high strength, chemical resistance, and durability. These materials are crucial for making aerospace composites that must withstand harsh environments.

Application:

Epoxy resins are vital in manufacturing structural components like wing surfaces and tail sections in aerospace, providing the necessary strength and resistance to environmental degradation required for critical structures.

If your aerospace components are struggling with weight constraints, thermal stress, or aerodynamic inefficiencies, Jairaj Group provides precision-engineered solutions. Our interior panels, insulation systems, and structural brackets use polycarbonate and PEEK to enhance fuel efficiency, thermal resistance, and overall performance while meeting the strict standards of aerospace components manufacturing.

Next, we’ll explore the specific types of aerospace plastic components that drive performance and reliability in aerospace systems.

5 Types of Aerospace Plastic Components

Plastic components play a key role in aerospace engineering by reducing weight while maintaining durability and functionality. Here are some common aerospace plastic components:

1. Exterior Components

Plastics like polycarbonate and acrylic are used for aircraft windows, canopies, and light covers. These materials provide optical clarity while offering the necessary impact resistance and UV protection.

2. Interior Components

ABS and polyamide are commonly used for cabin interiors, including armrests, seats, and stowage compartments. These plastics ensure both durability and comfort for passengers.

3. Structural Components

PEEK and epoxy resins are used in structural parts like brackets, beams, and housings, where high strength and resistance to harsh conditions are required.

4. Engine and Mechanical Parts

Polyimide and PEEK are used in fuel systems, seals, and bearing components, offering superior heat resistance and strength needed for engine parts under extreme conditions.

5. Electrical Components

Polyimide and epoxy resins are commonly used in wires, insulators, and connectors, ensuring that these components can handle the high temperatures and electrical loads encountered in aerospace systems.

Also Read: Thermoplastic Composites in Modern Aerospace Industry

Now that we’ve covered the types of components, let’s look deeper into the manufacturing techniques used to produce these precision plastic parts in aerospace.

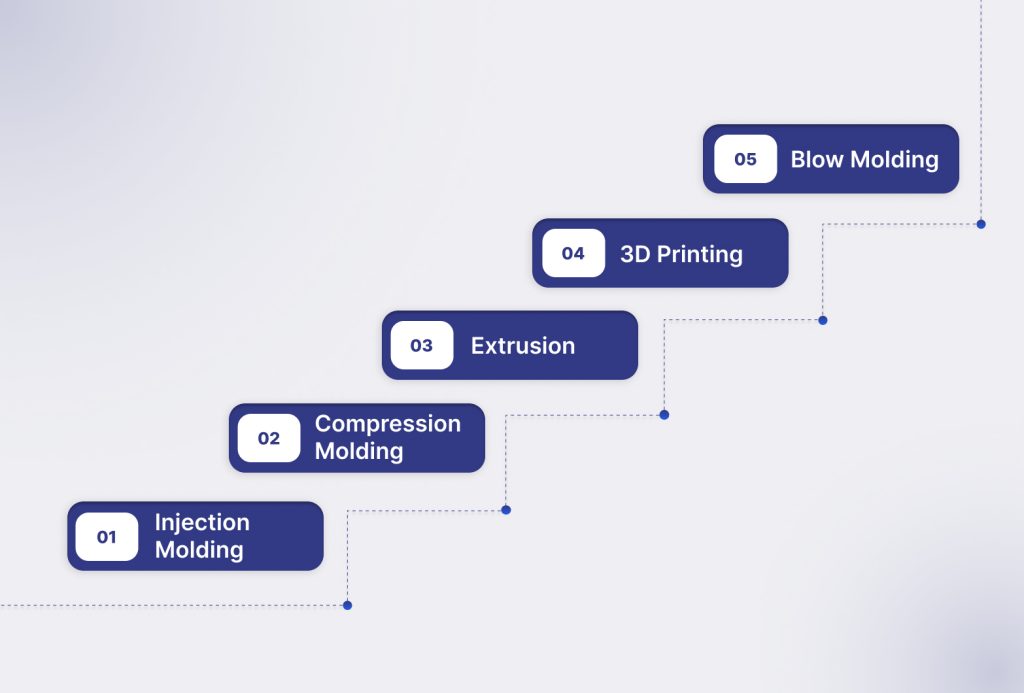

Techniques Used for Aerospace Plastic Manufacturing

To produce aerospace components with high precision, specialized manufacturing techniques are required. The following techniques help meet the industry’s strict standards for safety, quality, and performance.

Injection molding is used to create complex parts with high precision, including aircraft seating components, cabin interior panels, and control knobs. The process allows for high-volume production with minimal waste.

2. Compression Molding

This technique is used to produce strong, lightweight composite materials by pressing a plastic sheet into a mold. It is often used in wing panels, tail structures, and other large aerospace components.

Plastic extrusion is employed to create long, continuous shapes like pipes, profiles, and tubes used in aircraft fluid systems and electrical conduits.

4. 3D Printing

3D printing is increasingly used to produce prototype parts and complex components that are difficult to achieve through traditional methods. It is ideal for aerospace prototyping and low-volume production of custom components.

Blow molding is used to create hollow components such as fuel tanks, water bottles, and cylindrical structures. It offers high efficiency and precision for parts requiring specific shapes and internal volumes.

With an understanding of manufacturing techniques, it’s important to consider the design requirements for aerospace plastic parts, ensuring they meet all functional and regulatory standards.

Considerations for Designing Aerospace Plastic Parts

Designing aerospace parts from plastics involves more than just material selection. Key factors like weight, durability, and compliance with industry standards must be integrated into the design.

1. Weight Reduction

Lightweight materials are essential for improving fuel efficiency and performance. Aerospace plastics such as PEEK and polycarbonate offer the necessary strength while reducing weight in critical components.

2. Thermal Resistance

Materials must withstand extreme temperatures, especially in engine components or areas exposed to high heat. Polyimide and PEEK are perfect for these applications, offering superior thermal stability.

3. Chemical Resistance

Aerospace parts are exposed to various chemicals, including fuel, oil, and cleaning agents. Plastics like nylon and polypropylene offer excellent chemical resistance, ensuring the longevity of parts exposed to these substances.

4. Impact Resistance

Polycarbonate and acrylic are often chosen for parts that require high impact resistance, such as windows, canopies, and protective covers in aircraft.

5. Regulatory Compliance

All aerospace parts must meet strict industry standards for safety and performance. Aerospace plastics are selected not only for their physical properties but also for their ability to comply with regulations like FAA and ISO standards.

Also Read: Precision Components from Advanced Polymers for Automotive and Aerospace Applications

As we consider the design, let’s now look at the innovative applications of aerospace plastics and how they are revolutionizing the industry.

Innovative Applications of Aerospace Plastics

Aerospace plastics are used in a wide variety of applications, from engine parts to interior components. Their versatility helps optimize performance and reduce weight across aircraft systems.

1. Aircraft Interiors

Plastics like ABS and polycarbonate are used for seats, armrests, and cabin panels, combining durability with a lightweight design. These materials improve passenger comfort while maintaining performance.

2. Aircraft Exteriors

Polycarbonate and acrylic are used for canopies and windows, offering excellent transparency and UV resistance, while also being able to withstand impact and harsh weather conditions.

3. Structural Components

PEEK and epoxy resins are used for structural supports, brackets, and fasteners that must endure high stress and temperature extremes, contributing to the overall integrity of the aircraft.

4. Aerospace Engine Parts

High-performance plastics like polyimide and PEEK are used for fuel systems, gaskets, and seals, where heat resistance and chemical durability are essential.

5. Electrical Systems

Polyimide is used in insulation and wiring for its superior thermal and electrical resistance, ensuring the safety and longevity of aircraft electrical systems.

Also read: Top Plastic Manufacturers in 2025

Beyond innovative applications, it’s essential to recognize the advantages that aerospace plastics offer to manufacturers.

Advantages of Using Plastics in Aerospace Parts Manufacturing

The use of plastics in aerospace applications offers numerous advantages, including reduced weight, enhanced performance, and lower manufacturing costs. Here’s how aerospace plastics make a difference.

1. Lightweight

One of the main advantages of aerospace plastics is their ability to reduce the overall weight of aircraft, improving fuel efficiency and reducing operational costs.

2. Durability

Aerospace plastics are engineered for strength and resilience, capable of withstanding the high-stress environments encountered in both commercial and military aviation.

3. Corrosion Resistance

Many aerospace plastics are resistant to corrosion from fuels, oils, and other harsh substances, ensuring the longevity and performance of critical components.

4. Cost-Effectiveness

Compared to metals, plastics are often more cost-effective to manufacture and easier to handle, reducing overall production costs without compromising quality.

5. Design Flexibility

Plastics can be molded into complex shapes, allowing for intricate designs and lightweight structures that are not possible with traditional materials.

Also Read: Thermoplastic Composites in Modern Aerospace Industry

With these advantages in mind, it’s crucial to explore the future trends in aerospace plastics and how new innovations will shape the industry moving forward.

7 Future Trends in Aerospace Plastics Application

As the aerospace industry advances, new trends in aerospace plastics are shaping the future of aircraft design and performance. The following trends highlight the key advancements driving this transformation.

1. Increased Use of Sustainable Materials

The demand for bio-based and recyclable plastics is growing in aerospace, helping to reduce the carbon footprint while maintaining performance. Manufacturers are focusing on eco-friendly materials that align with sustainability goals.

2. Advanced Polymer Blends for Enhanced Performance

Polymer blends like combining polycarbonate with polyurethane or PEEK offer superior strength, heat resistance, and impact strength, making them ideal for high-stress aerospace components.

3. Smart Plastics and Embedded Sensors

Smart plastics with embedded sensors allow for real-time monitoring of critical components, improving safety and reducing maintenance costs through predictive insights and monitoring.

4. Lightweighting and Fuel Efficiency

Aerospace plastics like polycarbonate and nylon reduce the weight of aircraft, leading to better fuel efficiency. Lighter plastic composites are used for structural components and interiors to improve overall performance.

5. 3D Printing and Additive Manufacturing

3D printing with aerospace plastics allows for the creation of complex, custom parts with less waste, reducing production time and costs while offering design flexibility and lightweight solutions.

6. Hybrid Materials for Better Durability

Hybrid materials, combining plastics and metals, provide stronger, more durable parts for aerospace. Carbon fiber reinforced plastics (CFRPs) are used to achieve high performance with reduced weight.

7. Increased Focus on Regulatory Compliance

Aerospace plastics like PEEK and polyimide meet stringent FAA, ISO, and ASTM standards, ensuring high performance and durability while complying with safety regulations in aerospace applications.

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

Now that we’ve discussed future trends, it’s time to examine how selecting a high-quality plastic component supplier can enhance the overall aerospace manufacturing process.

Enhance Your Aerospace Manufacturing with High-Quality Plastic Components

In the world of aerospace manufacturing, precision and reliability are key when selecting the right components. Jairaj Group has been a trusted partner in providing plastic components, sheet metal parts, and assemblies across industries such as aerospace, automotive, and defense for over 35 years.

With facilities in Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand, we combine advanced R&D and cutting-edge production capabilities to deliver durable and high-performance solutions.

Here’s why you should partner with Jairaj Group:

- Advanced Technologies: We utilize plastic blow molding, injection molding, and rotational molding for producing brake & accelerator pedals, shockers & suspension components, and more.

- Wide Range of Materials: Our diverse range of materials, such as polycarbonate, PA 12, and PBT Arnite, ensures the highest performance in aerospace and automotive applications, including plastic bellows & struts and precision components from advanced polymers.

- Custom Solutions: We provide tailor-made solutions for critical components like interior & exterior accessories, braking system components, and mobility seating solutions that require exceptional durability and performance.

- Global Compliance: All our products meet regulatory standards, including ISO 9000, IATF, and CE certifications, ensuring that each component meets industry-specific safety and compliance regulations.

- Sustainability: We offer solar plastic components and eco-friendly alternatives, providing sustainable solutions without compromising the performance and durability needed in aerospace and heavy equipment applications.

Jairaj Group’s expertise extends to manufacturing brake & accelerator pedals, shockers & suspension components, and plastic bellows & struts, all built to meet rigorous industry standards. With certifications like ISO 9000, IATF, and CE, we ensure compliance with international quality and safety regulations, offering clients unmatched reliability and precision in every product.

Conclusion

The demand for aerospace plastics is driven by the need for lightweight, durable, and high-performance materials. Whether it’s polycarbonate for aircraft windows, PEEK for engine parts, or polyimide for wiring, the right aerospace plastics ensure long-term reliability and cost-efficiency.

Here’s how manufacturers can benefit from aerospace plastics without compromising performance:

Optimized Weight: Aerospace plastics like polycarbonate and PEEK reduce component weight, enhancing fuel efficiency and performance.

Superior Resistance: These plastics offer excellent UV, chemical, and weather resistance, ensuring long-term durability in harsh conditions.

Customization: A variety of plastics and technologies allow for tailored solutions to meet specific aerospace component needs.

With state-of-the-art facilities, precision manufacturing processes, and compliance with global certifications, Jairaj Group ensures that each component performs optimally under extreme conditions. We offer advanced plastic materials like polycarbonate, and polyimide, designed to meet the stringent standards of the aerospace industry.

Get in touch with Jairaj Group to explore how our aerospace plastic components can deliver top-tier performance in the aviation industry.

FAQs

1. Why is polycarbonate used for aerospace windows?

Polycarbonate offers superior impact resistance and optical clarity, making it ideal for aerospace windows, canopies, and light covers that must withstand extreme conditions.

2. What makes PEEK suitable for aerospace applications?

PEEK is known for its high strength, heat resistance, and chemical stability, making it ideal for critical aerospace components like engine parts and seals.

3. How does polyimide benefit aerospace wiring?

Polyimide offers excellent thermal and electrical resistance, making it ideal for aerospace wiring, insulation, and electrical components that must endure extreme temperatures and electrical loads.

4. Why is ABS used in aerospace interior components?

ABS is durable, impact-resistant, and cost-effective, making it ideal for interior components like dashboards, cabinets, and paneling while offering design flexibility.

5. What is the role of epoxy resins in aerospace composites?

Epoxy resins are critical for creating aerospace composites due to their strong bonding properties, which provide high strength, durability, and resistance to heat and chemicals.

6. How does nylon benefit aerospace mechanical parts?

Nylon provides high wear resistance, low friction, and thermal stability, making it ideal for aerospace gears, bearings, and moving parts that experience constant stress and high temperatures.