The aerospace industry seeks materials that combine strength, lightness, and reliability. Aerospace thermoplastic components are now leading this evolution, offering lightweight, durable, and flexible solutions that benefit manufacturers, operators, and passengers.

According to a report by Persistence Market Research, the market valuation for India’s thermoplastic composites is expected to expand to USD 5.2 billion (INR 38,400 crore) by 2031.

In this article, we’ll explore the role of thermoplastic composites in the modern aerospace industry and how they are reshaping design, performance, and sustainability.

Key Takeaways

- Thermoplastic composites offer high strength-to-weight ratios, boosting aerospace efficiency and performance.

- Unlike thermosets, they allow faster processing, repairability, and recyclability for lower lifecycle costs.

- Applications include fuselage panels, wings, nacelles, ducts, and cabin interiors, all meeting strict safety standards.

- Enterprises gain durability, longer service life, and reduced maintenance costs in demanding environments.

- Thermoplastic composites enhance sustainability by reducing weight, improving fuel efficiency, and supporting eco-friendly manufacturing in aerospace.

How are Thermoplastic Composites Crucial for Aerospace Manufacturers

Thermoplastic composites are advanced materials that combine polymers with reinforcements such as carbon fibers, glass fibers, or aramids. These composites are characterized by their ability to soften and flow when heated and solidify upon cooling. This ability makes them highly versatile and suitable for a wide range of applications.

In aerospace, thermoplastic composites are rapidly becoming essential due to their lightweight nature, superior mechanical properties, and ease of processing. Their integration into aircraft design helps achieve fuel efficiency, enhanced structural performance, and sustainability.

JaiRaj Group is at the forefront of supplying high-performance plastic composite components for the aerospace sector. With advanced materials like PA 12 and polycarbonate, JaiRaj offers products such as interior panels and structural brackets.

Also Read: Precision Components from Advanced Polymers for Automotive and Aerospace Applications

Benefits of Thermoplastic Composites in the Modern Aerospace Industry

Thermoplastic composites offer transformative benefits that directly impact efficiency, safety, and cost in aerospace. Their unique characteristics deliver significant improvements over older materials. Here are the main benefits of thermoplastic composites in aerospace:

1. Weight Reduction for Efficiency

Lighter structures reduce fuel consumption. Aircraft made with aerospace thermoplastic components save costs over their lifetime and reduce environmental impact through lower emissions.

2. Enhanced Design Flexibility

Thermoplastics allow engineers to create complex geometries without compromising strength. This design freedom supports next-generation aircraft structures and innovative interior layouts.

3. Maintenance and Repair Advantages

Thermoplastics can be reheated and reformed, making repairs easier and faster. This reduces downtime for airlines and extends component service life.

4. Improved Fatigue Resistance

Aircraft parts undergo repeated stress cycles. Thermoplastic composites resist fatigue better than metals, ensuring structural integrity over thousands of flight hours.

5. Lower Life-Cycle Costs

From manufacturing to operation, thermoplastics reduce expenses. Their durability, ease of repair, and recyclability translate into cost savings throughout the aircraft’s lifecycle.

6. Stringent Safety Standards

Aircraft materials must perform under extreme stress. Thermoplastics meet strict flammability, toxicity, and mechanical strength requirements, supporting compliance with safety regulations.

Given these benefits, it’s crucial to partner with a manufacturer offering tailored aerospace solutions. JaiRaj Group specializes in high-performance plastic components for interior panels, structural brackets, and thermal insulation, ensuring compliance with FST standards.

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

Now, let’s compare thermoplastics with traditional composites to better understand their distinct advantages.

How Do Thermoplastics Differ from Traditional Composites?

Thermoplastics differ significantly from conventional composites like thermosets. These differences extend beyond chemistry and affect performance, processing, and sustainability. Some of the most notable distinctions include the following aspects:

| Comparison Point | Thermoset | Thermoplastic |

|---|---|---|

| Curing vs. Melting | Uses thermoset resins that cure irreversibly, making reshaping impossible. | Melts when heated and solidifies upon cooling, allowing reshaping and recycling. |

| Processing Times | Requires long curing cycles, slowing down production times. | Offers faster processing, enabling high-volume production and quicker turnaround in aerospace. |

| Durability in Harsh Environments | Prone to brittle failure, less impact-resistant. | Withstands higher impact and crack propagation, ensuring longer service life in demanding conditions. |

| Weight and Fuel Efficiency | Lighter than metals, but offers less flexibility in design optimization for fuel efficiency. | Lighter than metals and more easily optimized for fuel efficiency due to flexible processing. |

| End-of-Life Recycling | Cannot be recycled once cured, often contributing to waste. | Recyclable, aligning with sustainability goals and reducing environmental impact. |

To clarify further, we’ll look at how thermoplastic and thermoset composites differ in aerospace applications.

Thermoset vs Thermoplastic Composites: Key Differences

The aerospace sector continues to evaluate thermoset and thermoplastic composites. Each has unique properties, but thermoplastics are increasingly recognized as the more adaptable choice. Here are the major differences:

| Comparison Aspect | Thermoset | Thermoplastic |

|---|---|---|

| Manufacturing Efficiency | Requires complex curing processes, increasing production times. | Streamlines manufacturing with quicker cycles and automation compatibility. |

| Mechanical Properties | Excellent heat resistance but prone to brittle failure. | Provides toughness, impact resistance, and strong thermal properties. |

| Repair and Reuse | Cannot be reprocessed once cured. | Can be reheated and reshaped, offering repair and reuse capabilities. |

| Sustainability Profile | Contributes to waste challenges at end-of-life. | Supports recycling and reduces the environmental footprint. |

| Industry Adoption Trends | Dominates legacy programs, especially in traditional applications. | Gaining traction in modern projects focusing on lightweight design and sustainability. |

Now, let’s examine the parts produced using thermoplastic composites and their real-world aerospace applications.

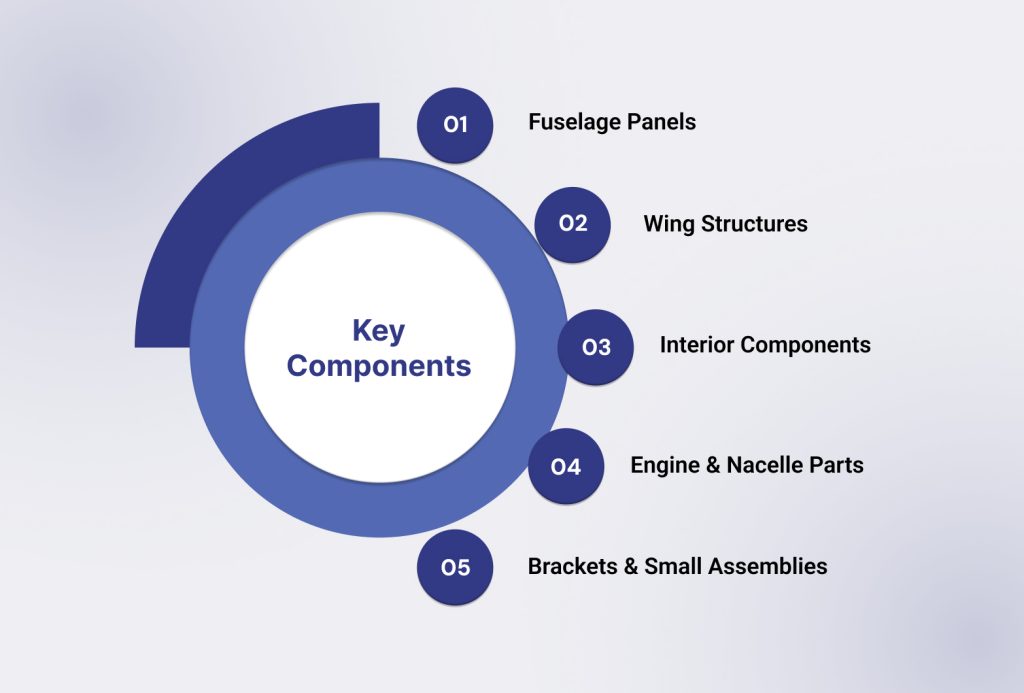

Key Components Produced Using Thermoplastic Composites for the Aerospace Industry

Thermoplastic composites are not limited to experimental applications. They are already used in key aircraft structures and interior components. Here are some examples of aerospace applications of thermoplastic composites:

1. Fuselage Panels

Lightweight yet durable fuselage panels reduce aircraft weight while maintaining cabin safety. Their impact resistance ensures integrity under extreme pressure and environmental conditions.

2. Wing Structures

Thermoplastic composites provide strength for wing spars, ribs, and skins. Their resistance to fatigue extends wing lifespan and ensures stable aerodynamic performance.

3. Interior Components

Seats, floor panels, and cabin linings use aerospace thermoplastic components. These parts meet flammability standards while reducing weight for better operational efficiency.

4. Engine and Nacelle Parts

Engine housings and nacelles benefit from thermoplastics’ heat resistance and toughness. Their performance in high-stress zones ensures both safety and reliability.

5. Brackets and Small Assemblies

Brackets, clips, and fittings made from thermoplastics cut down the metal use. Their lightweight properties contribute to significant aircraft weight savings across systems.

Also read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

To produce these parts, various materials are used, each enhancing performance in aerospace applications.

Top Thermoplastic Materials for Reliable Aerospace Applications

Thermoplastic composites use a variety of polymers and reinforcements, each offering specific advantages. The commonly used materials are as follows:

1. Polyetheretherketone (PEEK)

PEEK is a high-performance polymer with exceptional thermal and chemical resistance. It is widely used for structural parts requiring strength and durability under extreme conditions.

2. Polyetherketoneketone (PEKK)

PEKK offers similar strength to PEEK but has more processing flexibility. Its use in aerospace thermoplastic components supports complex geometries and demanding environments.

3. Polyphenylene Sulfide (PPS)

PPS provides excellent chemical resistance and dimensional stability. It is often used in brackets, electrical enclosures, and high-performance connectors in aerospace systems.

4. Polyimides (PI)

Polyimides handle high thermal loads effectively. They are used in components exposed to extreme heat, ensuring reliable performance without material degradation.

5. Reinforcing Fibers (Carbon/Glass)

Carbon and glass fibers are embedded within thermoplastic matrices to improve stiffness and strength. These reinforcements enable thermoplastics to compete with metals in demanding applications.

To meet industry standards for your next aerospace project, explore precision-engineered thermoplastic solutions needed to meet industry standards.

Get High-Performance Aerospace Solutions with Precision Thermoplastic Components

In modern aerospace, materials must achieve more than strength and lightness; they must meet strict global safety, compliance, and performance standards.

At Jairaj Group, we play a vital role in helping aerospace OEMs design and manufacture lightweight, durable, and precision-engineered plastic components that enhance efficiency, safety, and sustainability.

Here’s how we support aerospace with industry-specific solutions:

1. Aerospace-Grade Components

We manufacture interior panels, insulation systems, ducts, structural brackets, cabin wall trims, and seat back assemblies, all meeting fire, smoke, and toxicity (FST) regulations for global aviation safety.

2. Precision Components from Advanced Polymers

We specialize in injection molding tight-tolerance components using advanced polymers like PEEK, PC, PA66-GF, and TPU. These parts provide sealing, insulation, protection, and motion control for critical aerospace applications.

3. Lightweight Integrated Solutions

Our advanced polymers replace metals in duct brackets, cable guides, insulation mounts, and structural supports, reducing aircraft mass while improving vibration resistance, thermal stability, and fuel efficiency.

4. Diverse Manufacturing Technologies

Expertise across injection, blow, rotational, and extrusion molding, welding, assembly, machining, and custom tooling, enabling complex aerospace designs at scale.

5. Environmental & Regulatory Performance

Designed to withstand UV exposure, high altitudes, and extreme thermal conditions, our aerospace thermoplastic components deliver compliance and reliability across thousands of flight hours.

6. Sector-Specific Expertise

Trusted partner for aerospace, defense, mobility, automotive, heavy equipment, and industrial clients, delivering industry-ready performance in mission-critical applications.

7. Comprehensive Solutions Portfolio

From roto molding components and engineering tools to interior and exterior accessories, defense-grade assemblies, and aerospace thermoplastic components, we offer complete lifecycle support.

8. Global-Ready Compliance

With ISO 9000, ISO 14000, IATF, and CE certifications, we ensure every product aligns with international quality, environmental, and safety benchmarks.

By combining advanced polymers, precision molding, and global certifications, we help aerospace OEMs achieve lightweight integration, compliance, and performance at scale.

Conclusion

Aerospace thermoplastic components provide a proven pathway to stronger, lighter, and more sustainable systems. They deliver technical benefits and also business advantages, lower costs, compliance readiness, and extended service life. For decision-makers prioritizing reliability, precision, and collaborative partnerships, thermoplastics represent the future of advanced engineering.

Companies that integrate thermoplastic composites in the modern aerospace industry effectively achieve three major benefits:

- Enhanced durability by preventing deformation, creep, and failure in critical components.

- Extended operational life through resistance to heat, chemicals, and electrical stress.

- Optimized lifecycle cost by reducing maintenance, replacements, and downtime.

When optimizing existing component designs, partnering with Jairaj Group gives you access to advanced R&D, certified processes, and precision-driven plastic component manufacturing.

With facilities in Manesar, Sanand, and Aurangabad, we provide enterprises the opportunity to assess, prototype, and scale thermoplastic composites tailored for compliance.

Reach out to Jairaj Group to identify the right thermoplastic solutions for your aerospace applications.

FAQs

1. Why are thermoplastic composites gaining importance in the aerospace industry?

Thermoplastic composites are lightweight, durable, and recyclable. They improve fuel efficiency, reduce maintenance costs, and meet stringent global safety and compliance requirements.

2. How do thermoplastic composites compare to thermoset materials in aerospace applications?

Unlike thermosets, thermoplastics can be reheated and reformed. This allows easier repair, faster processing, and recycling, making them more cost-effective over their lifecycle.

3. Which aerospace components are commonly manufactured using thermoplastic composites?

Typical applications include interior panels, ducts, insulation systems, structural brackets, seat back assemblies, and fuselage sections, all designed to meet FST standards.

4. What certifications or standards do aerospace thermoplastic components need to meet?

They must comply with fire, smoke, and toxicity (FST) regulations, as well as international certifications such as ISO, IATF, and CE for safety and reliability.

5. How do aerospace companies benefit financially from using thermoplastic composites?

Companies save through fuel efficiency, extended component life, easier maintenance, and recyclability, reducing operational costs while ensuring long-term performance.