Across industries from automotive and EVs to appliances and aerospace, plastic ribs influence structural integrity, cycle times, and warranty costs. For example, the cooling phase of moulding components can increase cooling time by up to 50-80%, raising production costs.

Rib molding may seem minor, but it carries significant cost and program risks for OEMs and Tier-1 suppliers. But front-loading design-for-manufacturability (DfM) and working with certified, experienced suppliers ensures reliable plastic rib molding, reduces total cost of ownership, and accelerates time-to-market for OEMs and Tier-1 suppliers.

This article shows how to approach rib design as a business-critical decision, tying every design parameter to risk mitigation, cost efficiency, and supplier performance.

Key Takeaways

Optimize cost and weight: Reinforce parts without excess material, lowering resin usage and cycle time.

Prevent manufacturing defects: Proper rib geometry avoids warpage, sink marks, and ejection damage.

Ensure compliance and consistency: Design aligned to IATF 16949 and APQP streamlines PPAP approvals.

Reduce supplier risk: Standardized design rules support repeatability across global tooling sites.

Strengthen supply chain resilience: Partnering with capable suppliers ensures on-time, defect-free SOP launches.’

To understand the stakes, it’s crucial to know how ribs affect part performance.

Why Is Rib Molding Design Important in Injection Molding?

Rib molding is a strategic tool that enhances part performance while controlling cost and material use. By reinforcing walls without adding bulk, ribs help achieve structural integrity and dimensional stability in components ranging from interior trims to mechanical housings.

Before optimizing rib placement, it’s essential to understand their role in the part.

Ribs distribute mechanical stress more evenly across the part, reducing the risk of bending, warpage, or cracking.

They also enable functional features such as bosses, snap-fits, and mounting points, which can eliminate the need for additional hardware.

Beyond strength, ribs optimize material usage and weight, aligning with industry goals for lightweighting and cost efficiency.

Having looked at benefits, it’s time to explore how rib design affects manufacturability.

Effective rib design directly influences manufacturability. Correctly sized, spaced, and angled ribs minimize air traps, sink marks, and cycle times, reducing scrap and tooling rework.

For OEMs and Tier-1 suppliers, this translates into predictable production schedules, faster SOP launches, and compliance with quality standards such as IATF 16949 and PPAP.

Ensure robust part performance and streamlined production by implementing optimized rib molding strategies with JaiRaj Group, trusted by OEMs and Tier-1 suppliers for high-volume, precision components. Connect here.

Also read: Plastic Injection Molding: Precision Thermoplastic Components

Now, let’s break down the critical design factors procurement teams must focus on.

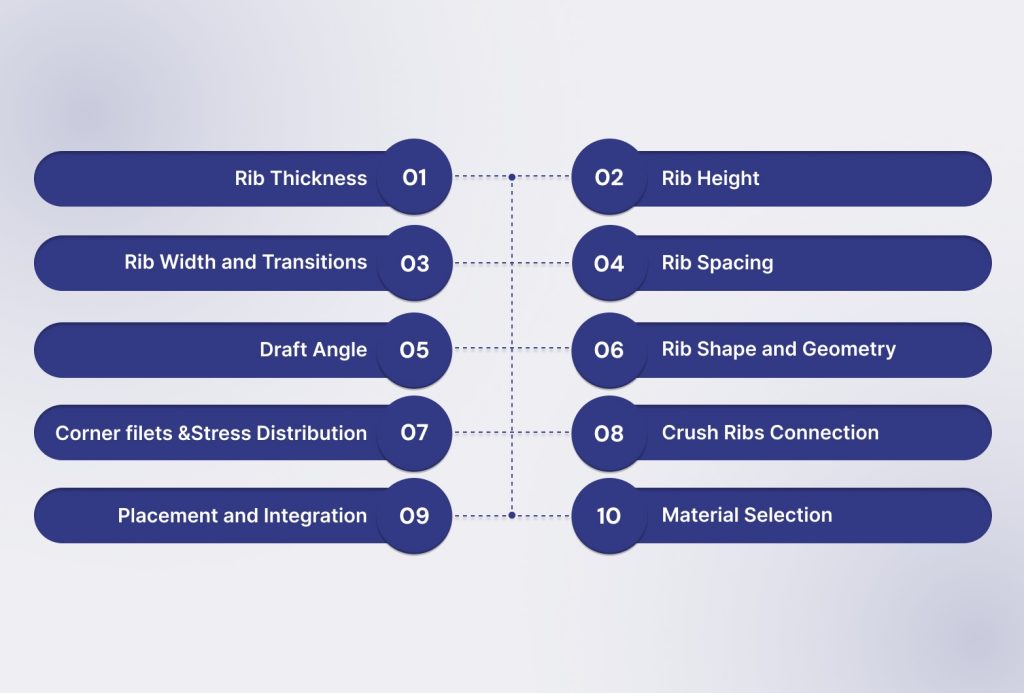

Rib Molding Design Factors Every Procurement Team Must Know

Ribs play a critical role in shaping durable, lightweight, and cost-effective plastic components. Designing them correctly isn’t just about strength. it affects cycle times, tool longevity, and overall part quality. Here’s what teams need to focus on to get rib design right:

1. Rib Thickness

Rib thickness is the primary determinant of sink marks, cycle time, and stress in molded parts. The recommended rib thickness is 60–75% of the nominal wall thickness, which ensures proper material flow without creating thermal bottlenecks.

Example: For a 5 mm wall, ribs should be designed at 3–3.75 mm. Avoid full-wall-thickness ribs, they trap heat, slow cooling, and can cause cosmetic defects.

Impact: Optimized thickness improves cycle consistency, reduces scrap, and prevents cosmetic rejects that could delay part approval.

2. Rib Height

Excessive rib height can lead to air traps, voids, and warpage during cooling. As a rule, rib height should not exceed 3× wall thickness.

Impact: Controlled rib height ensures dimensional stability, lowers tooling rework, and supports predictable production outcomes.

3. Rib Width and Transitions

The rib base should measure 0.5–0.7× wall thickness, with filet radii of at least 0.25× rib thickness (minimum 0.4 mm) at intersections.

Impact: Smooth transitions improve resin flow, reduce fill pressure, and extend tool life, leading to higher first-pass yield rates.

4. Rib Spacing

Ribs should be spaced at minimum 2× wall thickness, avoiding placement closer than the rib height.

Impact: Proper spacing promotes uniform cooling, reduces residual stress, and minimizes post-mold warpage, enhancing overall part reliability.

5. Draft Angle

Applying a 0.5°–1° draft (up to 2° for deep ribs) facilitates easy part ejection from the mold.

Impact: Draft reduces tooling wear, prevents part damage during ejection, and improves productivity across multiple production sites.

6. Rib Shape and Geometry

Ribs can take straight, T-shaped, L-shaped, or trapezoidal forms. Rounded or trapezoidal ribs distribute stress more evenly than sharp right-angled ribs.

Impact: Optimized rib geometry minimizes localized stress concentrations, reduces cracking risk, and enhances part longevity.

Also read: Precision Components from Advanced Polymers for Automotive and Aerospace Applications

7. Corner filets and Stress Distribution

Using filets (~0.25× rib thickness) at rib intersections decreases stress accumulation and avoids cracking.

Impact: filets improve long-term performance, reduce failure rates, and help maintain dimensional integrity under load.

8. Crush Ribs for Press-Fit Connections

Some ribs are designed to deform slightly for mechanical assembly. Controlled crush ribs enable press-fit attachments without additional hardware.

Impact: Enhances assembly efficiency, lowers secondary processing costs, and simplifies production workflows.

9. Placement and Integration

Strategic rib placement balances structural requirements with aesthetic and functional surfaces. Ribs should align with load paths while avoiding visible cosmetic areas.

Impact: Proper placement maximizes part stiffness, maintains visual quality, and reduces downstream issues during assembly.

10. Material Selection: Aligning Design with Resin Behavior

Material choice and manufacturing capabilities are key to effective plastic rib design. Polypropylene (PP) shrinks more, requiring thicker ribs, while ABS and PC/ABS blends allow thinner ribs with better dimensional stability.

Factors like mold complexity, machine tonnage, and cooling efficiency also shape rib geometry, height, spacing, and draft angles, directly affecting performance and manufacturability.

Glass-filled polymers: Require shorter, broader ribs to align fibers and prevent delamination.

Polypropylene (PP): Lightweight and cost-efficient, widely used for bumpers and trims. Vulnerable to petrochemical price volatility.

ABS / PC-ABS Blends: Deliver superior surface finish for interior components, but supply is concentrated in Asia-Pacific, creating sourcing risk.

Nylons (PA6/PA66): Ideal for high-strength parts such as pedals and gears. Dependent on adiponitrile feedstocks, which have experienced periodic global shortages.

Decision tip: Collaborate with suppliers to run CAD and mold-flow simulations early. This avoids late-stage redesigns that disrupt tooling schedules.

Before implementing, it’s essential to understand common pitfalls and their impact.

Risk Assessment: What Can Go Wrong in Rib Molding Programs

Even the most rigorously designed automotive and mobility programs can face delays or quality issues if rib molding risks are not addressed. Ribs play a critical role in structural strength, dimensional stability, and surface quality. Procurement leaders and program managers should focus on these five areas.

1. Excessive Rib Thickness

Ribs that are too thick can cause longer cooling times and inconsistent mechanical performance. On parts like Plastic Bellows & Struts and Shockers & Suspension Components, this can result in visible defects or compromised vibration absorption.

Mitigation: Maintain rib thickness at 60–75% of nominal wall thickness to balance strength, stiffness, and cosmetic quality.

2. Overly Tall Ribs

Ribs extending too far from the base wall risk warpage, trapped air, and dimensional distortion. Components such as Mobility Plastic Base Seating Solutions and Interior & Exterior Accessories are particularly sensitive because structural integrity and surface finish are critical.

Mitigation: Limit rib height to no more than 3× the wall thickness and validate designs with simulation tools before tooling begins.

3. Inadequate Rib Spacing

Poor spacing leads to uneven cooling and localized stress, increasing the likelihood of cracks or part deformation. This is a key concern for high-load or large-surface components such as Earth Movers & Heavy Vehicle Components.

Mitigation: Maintain minimum spacing of at least 2× wall thickness between ribs and reinforce critical areas with filets to distribute stress.

4. Lack of Draft on Ribs

Ribs without draft angles can stick in the mold, causing part damage and production delays. For high-volume items like Brake & Accelerator Pedals and Hand Grips, even minor sticking issues can cascade into significant downtime.

Mitigation: Apply 0.5°–1° draft per rib side to facilitate smooth mold release while preserving geometry.

5. Sharp Rib Intersections

Sharp intersections create stress concentration points that may lead to cracks or early failure, especially on parts exposed to dynamic loads or vibration, including Precision Components from Advanced Polymers and Roto Moulding Components.

Mitigation: Use filets of approximately 0.25× rib thickness at all intersections to improve stress distribution and part durability.

Takeaway: Addressing rib molding risks is only the first step. The true differentiator for procurement leaders and program managers lies in translating these insights into a strategic, repeatable process across suppliers and programs.

To mitigate risks, procurement teams should follow a structured roadmap.

Implementation Roadmap: De-Risking Texturing Across Global Chains

Procurement leaders protect program timelines and brand equity when they build surface texturing controls into the design phase instead of firefighting during launch. These five steps form a repeatable playbook to reduce rework, prevent cosmetic defects, and align suppliers across multi-site networks.

1. Lock Structural Parameters Early

Late design shifts in ribs, and bosses often cause tool rework, appearance issues, and SOP delays.

Best practice: Run Design-for-Manufacturability (DfM) workshops with suppliers before tool build to freeze rib geometry and wall transitions. This upfront alignment cuts weeks from tool tuning cycles and reduces retooling costs by up to 30%.

2. Deploy Simulation-Driven Validation

Undetected stress, warpage, and flow imbalances often escape until PPAP, when fixing them is costliest.

Best practice: Make simulation signoff mandatory for all appearance parts to predict stress hot spots, fill patterns, and warpage risk. This enables suppliers to correct design flaws before cutting steel, protecting launch schedules and reducing scrap rates.

3. Codify Enterprise-Wide Design Rules

Inconsistent rib practices across business units create unpredictable cost, tooling variation, and supplier churn.

Best practice: Build a centralized rib rulebook tied to corporate design standards and require compliance during sourcing. A shared rulebook ensures cross-site repeatability and accelerates supplier onboarding.

4. Safeguard Class-A Surface Integrity

Rib read-through and sink marks on visible panels escalate from cosmetic issues to brand damage and warranty costs.

Best practice: Define Class-A zones during design freeze and validate surface quality using structured inspection gates. This protects customer-facing aesthetics and avoids late-stage tool rework that can derail SOP readiness.

5. Institutionalize Cross-Site Quality Audits

Surface quality often slips when suppliers run multiple plants with uneven process maturity.

Best practice: Conduct regular audits focused on texturing depth control (SPI/VDI standards), etching capability, and post-texture finishing quality. This creates visibility into supplier consistency and flags risk before it disrupts production.

Executive takeaway: Procurement teams that treat texturing as a strategic quality lever rather than an isolated vendor task gain predictable costs, fewer launch delays, and stronger boardroom confidence in supply chain resilience.

Also read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

Finally, let’s see how aligning with the right supplier ensures rib performance and program reliability.

Strengthening Rib Design Through Strategic Supplier Evaluation

For OEMs, Tier-1 suppliers, and procurement leaders, the performance of ribs relies as much on supplier capability as on sound design. Early supplier alignment helps prevent warpage, and launch delays.

JaiRaj Group embeds supplier evaluation into rib molding programs through four key levers:

1. Early DfM and Mold-Flow Integration

Dedicated R&D and development centers in Faridabad, Manesar, Aurangabad, Sanand, and Rudrapur run in-house DfM and mold-flow reviews.

This ensures rib-heavy parts like Brake & Accelerator Pedals, Shockers & Suspension Components, and Precision Components from Advanced Polymers achieve structural strength and moldability from the RFQ stage, reducing rework and accelerating PPAP approval.

2. Certified Processes for Dimensional Stability

With ISO-9000, ISO-14000, IATF, and CE certifications, JaiRaj uses injection, blow, rotational, and extrusion moulding backed by plastic welding, machining, and tooling development.

These controlled processes deliver consistent geometry in ribbed parts such as Plastic Bellows & Struts, Mobility Plastic Base Seating Solutions, and Braking System Components used in automotive, railways, and defense sectors.

3. Precision Texturing and Class-A Finishes

JaiRaj applies controlled photoetching, laser texturing, and chemical etching with SPI/VDI-compliant depth control.

This delivers uniform surface finishes on ribbed components like Interior & Exterior Accessories, and Earth Movers & Heavy Vehicle Components, ensuring both structural and cosmetic quality for automotive, EV, and white goods industries.

4. PPAP-Ready Traceability and Quality Control

Each plant follows full PPAP protocols and traceability systems, providing documented material data and process records.

Rib-intensive parts such as Roto Moulding Components and Solar Plastic Components ship with verified audit trails, protecting quality and timelines on critical programs.

With over 35 years of experience as an Indian MSME, JaiRaj Group brings deep cross-industry expertise spanning automotive, mobility & EVs, heavy equipment, white goods, defense, aerospace, railways, drones, solar, and engineering tools.

This enables procurement teams to select suppliers based on proven capability, certified processes, and reliable delivery.

Conclusion

Rib design is not just a mechanical detail; it is a strategic lever that impacts cost, risk, and compliance across the program lifecycle. When prioritized early, it helps procurement, quality, and engineering leaders to:

Cut material usage and tooling costs without sacrificing strength

Avoid costly launch delays caused by design-related defects

Maintain part consistency and compliance across global production sites

By combining sound rib design principles with the capabilities of experienced partners, JaiRaj Group can help OEMs and Tier-1s reduce program risk, control TCO, accelerate launches, strengthen supply chain resilience, and secure a lasting competitive edge.

Contact JaiRaj Group to align supplier capabilities with your next injection molding program.

FAQs

1. Why are ribs preferred over thicker walls for part strength?

Thicker walls retain heat, leading to sink marks, warpage, and longer cycle times, all of which raise scrap rates and delay SOP. Ribs achieve the same structural rigidity with less material, reducing weight, cooling time, and per-piece cost.

2. What standards govern injection-molded components in regulated industries?

IATF 16949, ISO 9001, and APQP/PPAP protocols govern quality planning, process validation, and documentation traceability. Adhering to these ensures supplier accountability, audit readiness, and consistent part performance across multi-site production.

3. How do ribs influence mold cost and lifecycle economics?

Ribs reduce the need for thick cross-sections, which lowers tool steel volume, machining time, and cooling circuit complexity. This minimizes upfront tooling costs and extends mold life, directly improving total cost of ownership (TCO).

4. How can procurement teams evaluate supplier expertise in rib design?

Assess if suppliers provide early DfM support, mold-flow simulation, Class-A surface validation, and PPAP-proven programs across multiple sites. These capabilities reduce launch risk and prevent costly tool rework or dimensional failures.

5. How do ribs impact part weight and sustainability metrics?

Ribs enable lightweighting by replacing mass with geometry. This cuts resin usage, lowers energy demand per part, and supports corporate ESG goals while maintaining stiffness and crash performance requirements.

6. When are crush ribs the right choice in injection-molded assemblies?

Crush ribs are ideal for press-fit joints requiring tight tolerance control. They allow secure interference fits without secondary machining, reducing variation, assembly defects, and total cycle time in high-volume production.