The plastic automotive components market has seen tremendous growth over the past few decades, revolutionizing how vehicles are designed and manufactured. As the demand for vehicles continues to increase globally, automotive manufacturers are turning to plastics for more cost-effective, sustainable, and efficient solutions.

For example, a plastic bumper typically weighs 50% less than one made from alternative materials, while absorbing four to five times more energy. By incorporating plastics into both functional and aesthetic parts, automotive companies can improve vehicle performance while reducing production costs.

In this blog, we will examine the types of plastics used in automotive components, their applications, and how companies can choose the right material for their manufacturing needs.

Key Takeaways

- Plastics like polypropylene and polyamide are essential for improving vehicle performance and fuel efficiency.

- Advanced plastics like polycarbonate and ABS enhance both vehicle safety and aesthetics.

- Lightweight plastics contribute to fuel efficiency by reducing overall vehicle weight.

- TPE’s flexibility and durability make it ideal for automotive seals and gaskets.

- Polyethylene’s resistance to chemicals and durability make it perfect for fuel tanks.

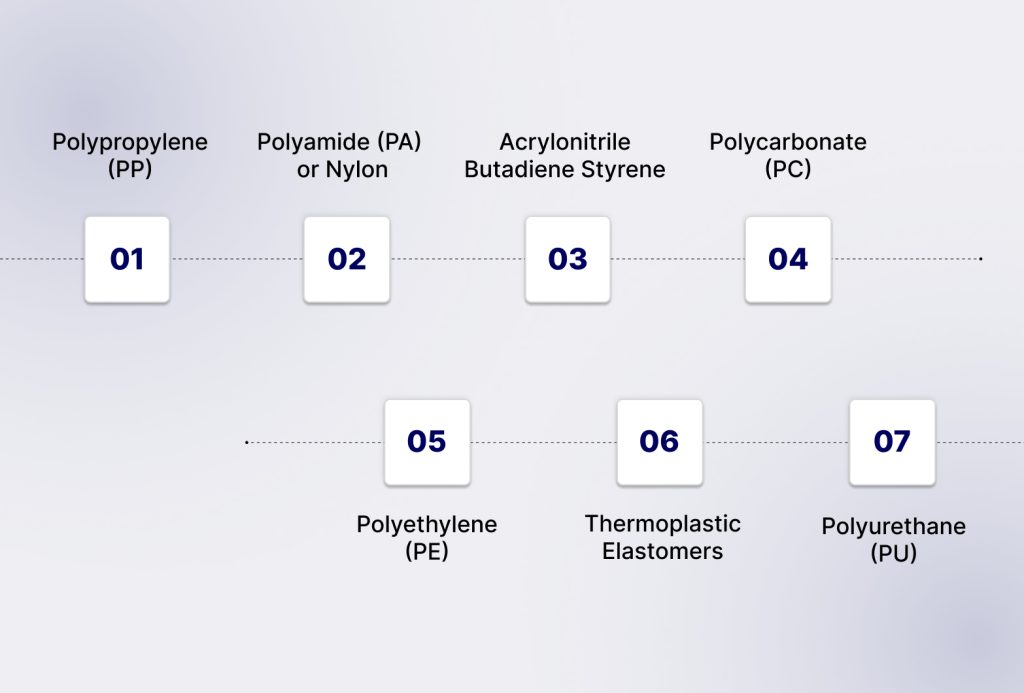

7 Types of Plastics Used in the Automotive Industry

The automotive industry uses a variety of plastics, each selected for its specific properties and performance characteristics. Below are some of the most commonly used plastics in automotive manufacturing:

1. Polypropylene (PP)

Polypropylene is known for its high durability, chemical resistance, and low cost, making it one of the most commonly used plastics in automotive manufacturing. It’s widely used in both interior and exterior components, contributing to vehicle efficiency by reducing overall weight.

Application: Polypropylene is used in dashboards, door panels, bumpers, and fender liners. Its lightweight nature enhances fuel efficiency by lowering vehicle weight.

2. Polyamide (PA) or Nylon

Polyamide (nylon) is a tough, heat-resistant plastic that provides exceptional mechanical strength and chemical resistance. It’s ideal for automotive parts subjected to high temperatures and mechanical stress, such as engine components and fuel lines.

Application: Nylon is used in engine components, fuel lines, and electrical connectors. Its high tensile strength ensures it performs well in demanding automotive environments.

3. Acrylonitrile Butadiene Styrene (ABS)

ABS is a tough, impact-resistant plastic known for its excellent finishing properties. It’s used in a variety of automotive components, especially where surface smoothness and durability are key, like interior panels and trim pieces.

Application: ABS is used in instrument panels, center consoles, and wheel covers. Its impact resistance and smooth finish make it perfect for both interior and exterior automotive parts.

4. Polycarbonate (PC)

Polycarbonate offers high impact resistance and optical clarity, making it ideal for transparent automotive parts. It’s also known for its lightweight nature and is used in various structural applications that require both strength and safety.

Application: Polycarbonate is used in headlamp lenses, windows, and rearview mirrors. Its toughness and clarity make it essential for both safety and aesthetic features in vehicles.

5. Polyethylene (PE)

Polyethylene is an economical plastic with excellent chemical resistance, making it ideal for automotive components that come into contact with fuels and oils. It’s also highly flexible, allowing it to endure stress without cracking.

Application: Polyethylene is primarily used in automotive fuel tanks and battery cases. It ensures chemical resistance and durability for parts exposed to harsh chemicals and liquids.

6. Thermoplastic Elastomers (TPE)

Thermoplastic elastomers (TPE) combine the elasticity of rubber with the processability of plastics, making them ideal for automotive seals and gaskets. TPE is often used in both functional and aesthetic applications that require flexibility and durability.

Application: TPE is used in gaskets, seals, weatherstrips, and trim. Its flexibility and durability under varying temperatures make it a popular choice for exterior and interior automotive parts.

7. Polyurethane (PU)

Polyurethane is versatile and widely used in automotive foam applications. It provides excellent energy absorption and impact resistance, making it ideal for seating and protective components like bumpers and door panels.

Application: Polyurethane is used in seat cushions, armrests, bumpers, and door panels. Its ability to absorb impact makes it crucial for enhancing vehicle safety and comfort.

If your automotive components are underperforming due to vibration, wear, or fluid leakage, Jairaj Group offers precision-engineered solutions. Using polycarbonate and polypropylene, we deliver spring pads, top caps, and custom reservoir caps. From mobility plastic seating solutions to plastic bellows & struts, our high-performance materials ensure durability, reliability, and OEM-grade precision in your production.

Knowing these materials is vital to understanding why plastics are so essential in modern automotive manufacturing.

Why are Plastics Essential for Modern Automotive Manufacturing?

The automotive industry’s adoption of plastics has been driven by several key benefits that these materials offer. Plastics provide numerous advantages over traditional materials like metal, including:

1. Lightweight and Fuel Efficiency

Plastics are lighter than metals, which reduces overall vehicle weight and improves fuel efficiency. This weight reduction is crucial for meeting fuel economy standards and lowering emissions.

2. Durability and Resistance

Plastics, like polypropylene and polyamide, resist corrosion, moisture, chemicals, and UV radiation, enhancing the longevity and reliability of automotive components exposed to harsh conditions.

3. Design Flexibility

Plastics allow for more intricate, complex shapes than metals, enabling innovative designs in both functionality and aesthetics. This flexibility makes them ideal for various automotive applications.

4. Cost-Effectiveness

Plastics are generally more affordable to manufacture than metals, reducing production costs. They can be produced quickly and in large volumes, contributing to further cost savings.

5. Safety

Plastics like polycarbonate offer excellent impact resistance, enhancing vehicle safety. They also help reduce weight, improving overall safety by lowering the risk of injury in collisions.

Also Read: Precision Components from Advanced Polymers for Automotive and Aerospace Applications

With plastics playing such a crucial role, choosing the right plastic becomes the next key consideration in the automotive manufacturing process.

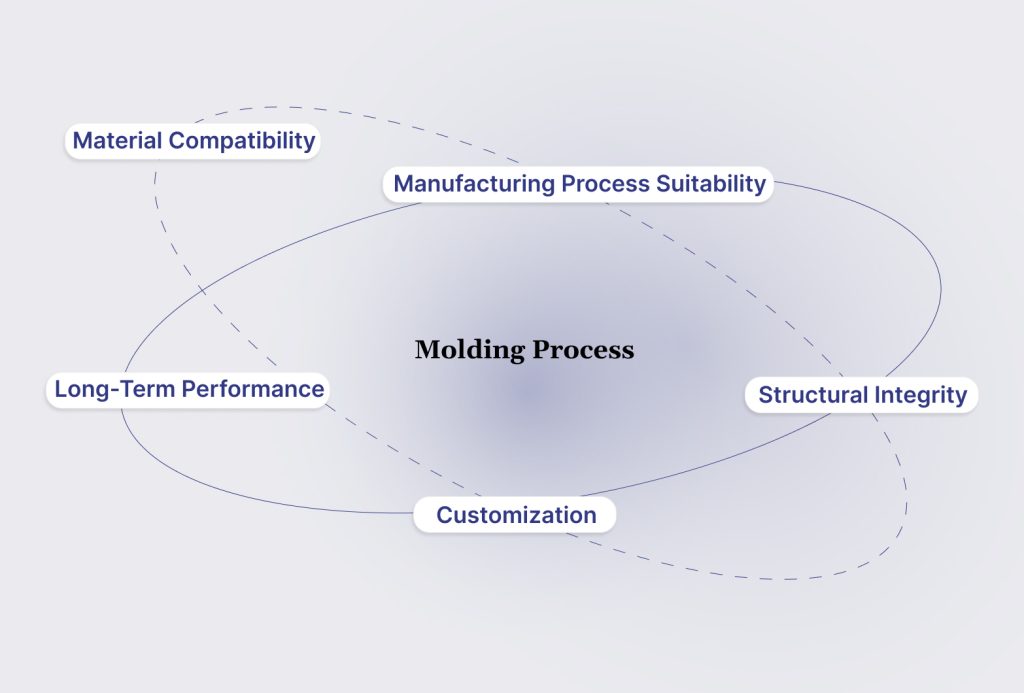

How to Choose the Right Plastic for Your Automotive Business?

Selecting the right plastic material for automotive applications ensures that components meet performance standards and comply with regulations. Here are key factors to consider when choosing the best plastic for automotive components:

1. Material Compatibility

When selecting plastic, it’s important to consider how it interacts with other materials, such as metals or glass. Compatibility ensures that parts function well together, especially in assemblies with mixed materials.

2. Manufacturing Process Suitability

Different plastics are suited for different manufacturing processes, such as injection molding or blow molding. Manufacturers should choose plastics that are compatible with their chosen production methods to ensure efficiency and quality.

3. Structural Integrity

Plastics offer weight-saving advantages, but their strength must align with the structural requirements of the part. For heavy-duty applications like bumpers, plastics must offer both strength and lightweight properties.

4. Customization

Plastics allow for intricate designs and complex shapes, providing greater flexibility in vehicle manufacturing. Manufacturers should select plastics that support the desired functionality and aesthetic appeal for each component.

5. Long-Term Performance

Auto manufacturers must evaluate the long-term performance of plastics, including their ability to withstand wear, impact, and exposure to harsh environments. Durability is critical for parts that need to last the life of the vehicle.

Also Read: Automotive Interior & Exterior Plastic Parts Manufacturing: Trends and Innovations in 2025

As you make these decisions, it’s equally important to keep an eye on the future trends of automotive plastics.

Future of Automotive Plastic Materials: Opportunities for Manufacturers and OEMs

The future of plastic automotive components is advancing with cutting-edge innovations that are transforming vehicle manufacturing. Here are key developments to watch:

- Smart Plastics with Embedded Sensors: The integration of sensors within plastic parts will enable real-time monitoring of vehicle components, improving maintenance and performance tracking for automakers.

- Lightweight High-Performance Plastics: Advances in lightweight materials like thermoplastic composites are driving the shift towards vehicles with reduced weight while maintaining high strength, especially for electric vehicles (EVs).

- Self-Healing Plastics: Researchers are developing self-healing plastics that can repair small scratches or cracks automatically, increasing the durability and longevity of automotive parts.

- Recyclable and Biodegradable Plastics: As sustainability becomes a priority, the automotive industry will incorporate more recyclable and biodegradable plastics, reducing environmental impact while maintaining performance standards.

- 3D Printing for Custom Plastic Parts: 3D printing technology will continue to advance, allowing for more precise, on-demand production of complex plastic components, reducing waste and speeding up prototyping.

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

With these innovations in mind, ensuring you select the right materials for your production needs will solidify your position in the market.

Select Premium Plastic Components for Your Automotive Manufacturing Process

The automotive industry is increasingly turning to advanced plastic materials for their ability to reduce weight, enhance durability, and cut production costs. At the center of this transformation is the Jairaj Group, a prominent Indian MSME that is spearheading innovation in the production of plastic components with a focus on precision parts and assemblies.

With certifications such as ISO 9000, ISO 14000, IATF, and CE, Jairaj Group ensures compliance with global quality, environmental, and safety standards, supporting OEMs, Tier-1 suppliers, and specialized industrial manufacturers.

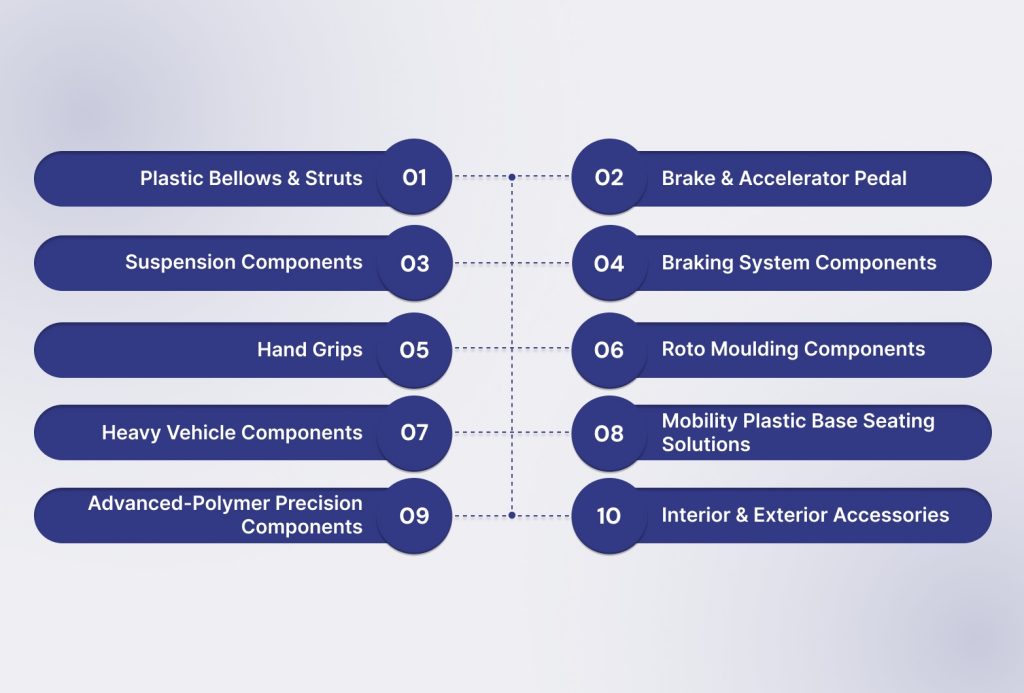

Below, we’ll explore some of their key products tailored for automotive manufacturing.

- Plastic Bellows & Struts: Used in automotive, two- and three-wheelers, railways, and earthmover vehicles, offering flexibility and durability for high-performance applications.

- Brake & Accelerator Pedal: Manufactured for automotive and heavy-duty vehicles, providing precision and strength for critical vehicle control components.

- Shockers & Suspension Components: Designed for automotive, two-wheelers, and earthmovers, ensuring stability and smooth ride quality.

- Braking System Components: Precision-engineered parts for reliable braking systems in vehicles, including automotive, two-wheelers, and defense applications.

- Earth Movers & Heavy Vehicle Components: Strong, durable components for heavy-duty vehicles and earthmovers, designed to withstand challenging conditions.

- Hand Grips: Ergonomic, durable grips for two- and three-wheelers and automotive, enhancing comfort and control.

- Roto Molding Components: Suitable for engineering tools, white goods, defense components, and aerospace, with robust performance.

- Mobility Plastic Base Seating Solutions: Lightweight, comfortable seating solutions for automotive, two-wheelers, and railways.

- Precision Components from Advanced Polymers: High-precision components for automotive, aerospace, and defense industries, ensuring reliable performance under demanding conditions.

- Interior & Exterior Accessories: High-quality interior and exterior accessories, which include trim pieces, dashboards, and door panels, add both function and style to vehicles.

Advanced Technologies Used by Jairaj Group:

- Plastic Blow Molding: For manufacturing flexible, durable components such as bellows, hand grips, and seating solutions.

- Plastic Injection Molding: Used for producing brake pedals, shockers, suspension parts, and precision components with high accuracy.

- Plastic Rotational Molding: Ideal for producing roto molding components and heavy vehicle components with exceptional strength.

- Extrusion Molding: Applied in producing bellows, hand grips, pipes for heavy vehicles, and solar components.

- Plastic Welding & Assembly Lines: Provides seamless joining of shockers, suspension parts, and interior components for optimal performance.

Jairaj Group operates multiple modern facilities in Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand, combining in-house R&D, advanced tooling, and cutting-edge production capabilities to deliver high-quality solutions that meet the strictest industry standards.

Conclusion

The use of plastic automotive components paves the way for lighter, more efficient, and durable vehicle systems. These materials not only enhance vehicle performance but also offer cost-effective and sustainable solutions for manufacturers. For those focused on innovation, reliability, and reducing environmental impact, plastics are an essential element in automotive engineering.

By incorporating common plastics into automotive components, companies can achieve significant advantages:

- Enhanced durability of key parts, ensuring they withstand the rigors of daily use and environmental challenges.

- Increased lifespan of components, providing resistance to heat, chemicals, and physical wear, reducing the need for frequent replacements.

- Cost savings through weight reduction, which improves fuel efficiency and optimizes production processes.

Partnering with Jairaj Group enables manufacturers to use advanced manufacturing techniques, cutting-edge R&D, and a wide range of high-quality plastic materials. Whether you’re working with polypropylene, polyamide, polycarbonate, or ABS, Jairaj Group delivers tailored plastic solutions that maximize both performance and efficiency.

Reach out to Jairaj Group to discover how we can help optimize your automotive components with precision-engineered plastic solutions.

FAQs

1. What role does polyamide (nylon) play in automotive components?

Polyamide (nylon) is used for high-performance automotive parts, offering strength, heat resistance, and durability, making it ideal for engine components and fuel lines.

2. How does polypropylene help improve fuel efficiency in vehicles?

Polypropylene reduces vehicle weight, contributing to better fuel efficiency while being durable and resistant to chemicals, making it ideal for both interior and exterior parts.

3. Why is polycarbonate used for automotive headlamps?

Polycarbonate is impact-resistant, lightweight, and has optical clarity, making it perfect for headlamp lenses and ensuring safety and visibility in vehicles.

4. What makes thermoplastic elastomers (TPE) suitable for automotive seals?

TPE offers both flexibility and durability, making it ideal for automotive seals and gaskets that need to perform under varying temperatures and weather conditions.

5. How does ABS contribute to automotive safety?

ABS’s impact resistance makes it an excellent choice for interior and exterior automotive components like bumpers, enhancing safety by absorbing shock during collisions.

6. What are the advantages of using polyethylene in automotive fuel tanks?

Polyethylene is chemically resistant, flexible, and durable, making it the ideal choice for automotive fuel tanks that must withstand exposure to fuels and other harsh chemicals.