Selecting the right molding process is essential for producing high-performance components in automotive, aerospace, defense, and heavy machinery, where durability and compliance matter most.

With India’s manufacturing sector set to reach Rs. 87,57,000 crore by 2026, OEMs and Tier-1 suppliers are seeking local partners who meet global standards. Comparing blow molding vs rotational molding helps clarify which solution suits lightweight tanks, large containers, or industrial parts.

This blog explains the key differences and helps you choose the right manufacturing solutions to minimize your supply chain risk and create long-term value in both Indian and global markets.

At a glance:

- Blow Molding is perfect for high-volume production of uniform, precise parts like bottles and fuel tanks, with fast cycle times under one minute.

- Rotational Molding shines at low-to-medium volumes of large, complex parts with thick walls and custom features, offering superior design flexibility despite longer cycle times.

- Blow molding requires expensive steel molds, but they last longer, while rotational molding uses more affordable aluminum molds, making it great for prototypes and frequent design changes.

- Choose blow molding for mass production that needs speed, precision, and consistent quality.

- Choose rotational molding for custom and complex geometries or specialized applications that require flexibility.

Key Principles of Blow Molding and Rotational Molding

Blow molding is a manufacturing process that uses air pressure to form hollow plastic parts, while rotational molding involves rotating a mold to evenly distribute plastic material, creating larger, thicker-walled components.

Here’s a breakdown of how blow molding and rotational molding work and which process is best for your needs:

Blow Molding: High-Volume Production with Precision and Efficiency

Blow molding starts with creating a parison, a tube-like shape of plastic. This parison is inserted into a mold, and compressed air inflates it to take the shape of the mold.

- Precision & Efficiency: The control of air pressure and volume directly impacts the final product’s thickness, uniformity, and dimensional accuracy, making it ideal for industries that require consistent quality.

JaiRaj Group excels in producing high-precision, blow-molded parts like plastic bellows & struts for the automotive industry, ensuring both quality and durability.

Rotational Molding: Versatility in Design and Thickness

Rotational molding (or rotomolding) is ideal for creating larger, thicker, and more intricate hollow parts. Unlike blow molding, which uses compressed air, rotomolding relies on gravity and controlled rotation to achieve uniform thickness and a seamless finish.

- Process Overview: A measured amount of plastic powder is placed inside a mold, which rotates on two perpendicular axes while being heated. The rotation ensures the resin coats the mold evenly, resulting in a smooth and consistent thickness without needing high-pressure equipment.

For parts that require increased thickness and custom geometries, rotational molding offers a high degree of flexibility. At JaiRaj Group, we specialize in rotomolded components designed for heavy-duty applications, such as earth movers and industrial machinery parts, ensuring optimal performance even in the harshest conditions.

However, choosing the right molding process depends on your specific product requirements. Understanding these distinct characteristics will help you make an informed decision.

Differences Between Blow Molding and Rotational Molding

Both techniques are widely used in producing hollow plastic components for industries like automotive, aerospace, defense, and industrial machinery. However, they differ significantly in terms of mold characteristics, design flexibility, and other aspects.

Let’s break down the differences between blow molding and rotational molding in simple terms, helping you make the best choice for your production needs.

| Aspect | Blow Molding | Rotational Molding |

| Mold Characteristics |

|

|

| Design Flexibility |

|

|

| Material Selection |

|

|

| Production Volume | Ideal for high-volume production | Suited for low-to-medium production runs |

| Cost Considerations |

|

|

| Part Size and Complexity |

|

|

| Cycle Time | Rapid cycle times, often under 1 minute, with highly automated processes |

|

| Suitability for Prototypes | Not ideal for prototypes due to high tooling costs | Ideal for prototypes and design changes due to affordable tooling and flexibility |

| End Use Applications | Automotive fuel tanks, consumer packaging, and bottles | Storage tanks, aerospace components, industrial machinery parts, and custom enclosures |

At JaiRaj Group, we specialize in both molding techniques, offering tailored solutions that meet the demanding standards of industries like automotive, defense, and many more. If you’re looking for precision-engineered components that align with your specific needs, we’re here to support your next project.

For procurement managers, design engineers, or R&D leaders choosing between blow molding and rotational molding can be a strategic decision that impacts your product’s performance and long-term success.

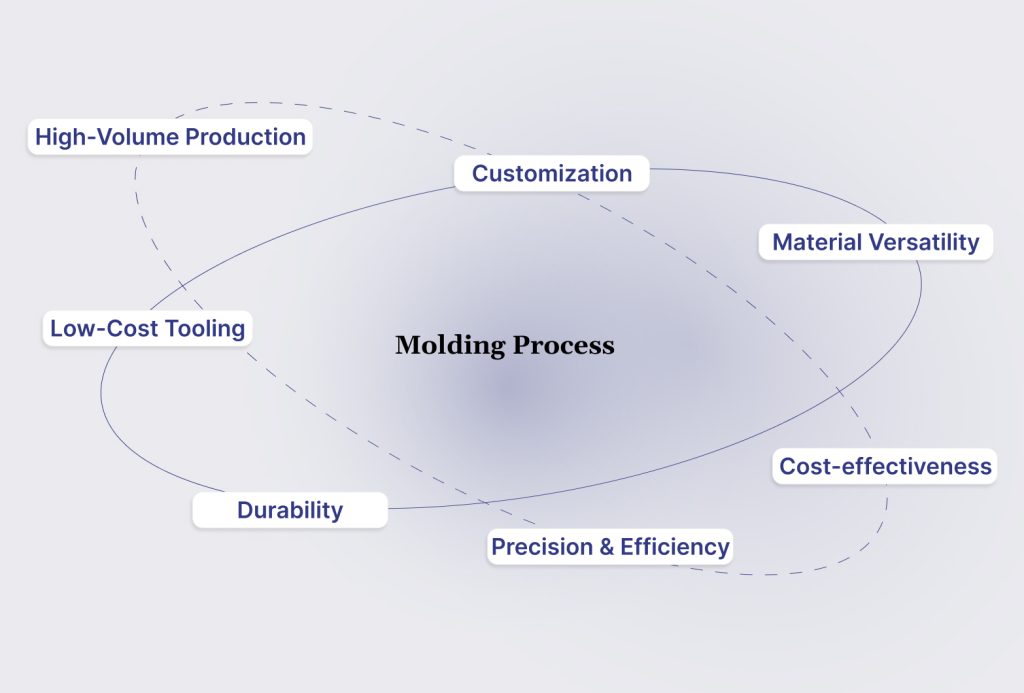

Which Molding Process is Right For You to Choose?

Choosing between blow molding and rotational molding depends on several factors, including the type of parts you need, production volume, and cost-efficiency. Here’s a breakdown to help you determine the right process for your needs:

- High-Volume Production: If your business requires large-scale production with consistent, uniform parts, blow molding is the best option. This process is ideal for producing thousands of identical parts quickly, making it perfect for items like automotive fuel tanks and consumer goods packaging.

- Customization & Complex Designs: For large, intricate parts with custom features like internal cavities or stiffening ribs, rotational molding is more suitable. This process excels at low-to-medium production volumes and can accommodate complex geometries, such as aerospace housings or industrial machinery components.

- Material Versatility: If you need high-performance materials with special properties, such as UV resistance or flame retardancy, rotational molding offers greater material flexibility. This makes it ideal for parts that will be exposed to harsh environments, ensuring durability and longevity.

- Cost-Effectiveness in Low Runs: For small production runs or prototypes, rotational molding is more cost-effective. Tooling costs are lower, and the process allows for rapid design changes, making it a great choice for industries like defense or aerospace, where custom parts might be needed on demand.

- Precision and Efficiency: If speed and precision are crucial, blow molding is the right choice. It delivers short cycle times and is highly automated, making it ideal for mass production of standard parts like bottles, containers, and automotive parts.

- Durability for Long-Term Production: Blow molding molds are designed for long-term durability, with the ability to endure tens of thousands of cycles. Although the initial tooling investment is higher, the long-term return makes it ideal for high-volume, long-lifecycle production runs.

- Low-Cost Tooling & Quick Modifications: If you need affordable tooling and the ability to quickly modify designs, rotational molding offers the flexibility you need. This is especially beneficial for industries like heavy equipment or custom machinery, where production needs can change frequently.

Choosing the right molding process hinges on your specific production needs. Whether you prioritize speed, flexibility, cost, or durability, both processes have their unique strengths.

With over 35 years of experience, JaiRaj Group combines blow molding and rotational molding to deliver top-quality solutions for industrial applications.

Also Read: How to Choose the Right Plastic Product Supplier for Automotive & Industrial Components

Precision Manufacturing Solutions Across Multiple Technologies

We bring together a wide range of manufacturing technologies, including injection molding, blow molding, rotational molding, and extrusion, all backed by in-house R&D, advanced tooling, and rigorous quality systems (ISO 9000, ISO 14000, IATF, and CE certifications).

What sets us apart:

- Multi-technology expertise: Whether you need high-volume blow-molded plastic bellows & struts or intricate rotomolded aerospace components, we have the right process for your project

- Materials mastery: We work with a range of high-performance polymers, like Nylon GF, PBT Arnite, and specialized compounds with UV resistance and flame retardancy, to meet your performance needs

- End-to-end support: From design and prototyping to production and technical support, we manage your project from start to finish

- Industry compliance: Our components meet the strict standards of automotive OEMs, defense contractors, and aerospace manufacturers

- Advanced manufacturing capabilities: Multiple plastic welding techniques, precision machining, assembly lines, and custom mold development for complete part solutions

- Geographic coverage: Strategic facilities across Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand for reliable supply chain support

- Proven track record: 35+ years serving automotive, defense, aerospace, heavy equipment, and industrial sectors with precision-engineered components

Our blow molding expertise includes:

- Plastic bellows & struts for automotive and heavy vehicle applications

- Hand grips for two and three-wheelers

- Mobility seating solutions with integrated features

Our rotational molding solutions cover:

- Large-scale rotomolding components for engineering tools and white goods

- Earth mover & heavy vehicle components with enhanced durability

- Defense and aerospace housings requiring complex geometries

Our engineering team is here to work with you, ensuring the best design, materials, and manufacturing approach for your needs.

Conclusion

Selecting between blow molding and rotational molding ultimately depends on your specific production requirements, volume needs, and design complexity. While blow molding excels in high-volume, precision manufacturing, rotational molding offers unmatched design flexibility for complex, large-scale components.

The right choice impacts not just manufacturing costs, but also product performance, time-to-market, and long-term scalability. Many procurement managers struggle with this decision, especially when balancing quality standards with supply chain risks.

Are you having difficulty choosing the optimal molding process for your components? Contact JaiRaj Group to explore how our multi-technology capabilities in both blow molding and rotational molding can support your next project.

Frequently Asked Questions

1. What are the typical lead times for tooling in blow molding vs rotational molding?

Blow molding tooling typically requires 8-12 weeks due to the complexity of steel molds, precision machining, and cooling channel integration. Rotational molding tools can be ready in 4-6 weeks since aluminum molds are simpler to manufacture and require less intricate features.

2. What wall thickness ranges are achievable with the blow molding vs the rotational molding process?

Blow molding typically produces wall thicknesses of 0.5-3mm with excellent uniformity. Rotational molding can achieve thicker walls ranging from 3-25mm, making it ideal for structural applications requiring higher impact resistance.

3. How do surface finish quality and appearance compare between the blow molding and the rotational molding process?

Blow molding delivers a superior surface finish with minimal parting lines and excellent detail reproduction, making it ideal for consumer-facing products. Rotational molding produces a slightly textured “orange peel” surface with visible parting lines, though this can be minimized through proper mold design.

4. Can inserts or threaded features be molded directly into parts?

Blow molding can incorporate simple threaded necks and basic inserts, though complex features require secondary operations. Rotational molding excels at molding in metal inserts, threaded fittings, and complex internal features during the molding cycle.