Looking for a cost-effective way to produce strong, durable parts without compromising on quality? Rotomolded plastic offers a reliable solution for manufacturers who want to balance performance with affordability.

It can create large, complex, and hollow parts without seams or joints. This ensures both design flexibility and long-lasting strength.

Its ability to handle high-impact conditions makes it even more appealing. The simple production process also keeps tooling and maintenance costs low. Together, these advantages make rotomolding an efficient choice for many manufacturing needs.

In this blog, you’ll take a closer look at the key benefits of rotomolded plastic and how it can improve your production process from start to finish.

Key Takeaways:

- Rotomolding is a cost-effective option, especially for medium- to low-volume production, as it has lower tooling and maintenance costs than injection molding.

- It’s ideal for creating large, complex, and hollow parts without seams or joints, giving manufacturers greater design flexibility.

- The process works with a variety of plastic materials, including PE, PP, and PVC, allowing products to be tailored for impact resistance, UV stability, or chemical protection.

- Rotomolding also reduces waste by using recyclable resins and reducing scrap, making it an environmentally friendly manufacturing method.

- Another advantage is that it produces parts with consistent wall thickness, ensuring uniform strength and reliable performance in every batch.

What is Rotomolded Plastic & Why It’s Useful?

Rotomolding is a unique process in which plastic resin is placed in a mold, heated, and then rotated along two axes. This rotation evenly distributes the material, creating hollow parts with smooth, seamless walls.

The result is a strong, durable product, ideal for OEMs and Tier-1 suppliers in industries such as automotive, heavy equipment, and defense, where performance and reliability matter most. Rotomolded plastic helps in:

Cost Efficiency and Lower TCO

Rotomolding stands out for its cost savings, both during production setup and throughout a product’s lifetime.

For example, components like Plastic Bellows and Struts used in automotive and industrial applications can be produced more cost-effectively using rotomolding. This process ensures long-term durability and helps reduce maintenance costs over time.

- Lower Tooling and Maintenance Costs: The molds used in rotomolding are simpler and more affordable than those in injection molding, cutting down initial setup costs.

- Long-Term Savings: The process requires less maintenance and upkeep, thereby reducing the Total Cost of Ownership (TCO). For OEMs, this means greater cost efficiency and better returns over time.

Design Flexibility

One of rotomolding’s biggest strengths is its ability to create large, complex parts without losing structural integrity. Roto-moulded components like tanks and protective enclosures are perfect for industries that need large, hollow parts with smooth, seamless surfaces and high precision.

- Freedom in Design: It allows manufacturers to produce detailed, intricate shapes without seams or joints, something that’s difficult to achieve with other molding techniques.

- Ideal for Large Parts: The process is well-suited for making large, hollow parts such as fuel tanks, containers, or heavy-duty equipment covers that need to remain strong and stable.

Material Customization

Rotomolding supports a wide range of plastic materials. This gives manufacturers the flexibility to tailor parts for specific needs and performance goals. For example, precision components made from advanced polymers perform reliably in environments that demand both heat and chemical resistance.

- Diverse Material Options: Common choices include polyethylene (PE), polypropylene (PP), and PVC, each offering unique benefits such as impact strength, UV protection, or chemical resistance.

- Built for Durability: By choosing the right material, OEMs can ensure their parts perform well under different conditions, whether that means withstanding outdoor weather or handling constant mechanical stress.

Supply Chain Resilience

Maintaining a steady, reliable supply chain is critical for manufacturers. Rotomolding supports this by ensuring consistent quality and dependable production timelines.

For instance, Handbrakes and hand grips in mobility products perform better when made through rotomolding. This ensures consistent quality and dependable production timelines.

- Consistent Quality: The process delivers uniform quality across every batch, reducing the chances of defects or rework.

- Reliable Timelines: Rotomolding’s efficiency supports smooth production schedules and on-time deliveries, minimizing risks of supply interruptions or stock shortages.

Compliance with Industry Standards

In industries such as automotive and defense, meeting strict standards is essential. Rotomolding helps manufacturers stay compliant and competitive.

Braking system components made through rotomolding meet global benchmarks, ensuring reliable performance even in demanding conditions.

- Certified Quality: The process supports compliance with key certifications, including IATF 16949 for automotive and ISO 9001 for quality management, ensuring that parts meet global benchmarks.

- Performance-Ready: Rotomolded components are engineered to withstand demanding environments, providing the durability and safety required for high-performance applications.

Ensure strong part performance and cost-effective production by implementing optimized rotomolding strategies with JaiRaj Group, a trusted partner for OEMs and Tier-1 suppliers in the automotive industry. Connect with us here.

How Rotomolding Compares with Other Plastic Moulding Methods?

When choosing a molding process, think about your part’s shape, size, durability, and cost. Each method has its strengths, but rotomolded plastic often stands out for large, hollow, or complex components.

Here’s how rotomolding compares with other common processes like injection molding and blow molding, and where each one performs best.

| Criteria | Rotomolding | Injection Molding | Blow Molding | Compression Molding |

|---|---|---|---|---|

| Part Size & Complexity | Large, complex, hollow parts | Smaller, intricate parts, limited by part size and shape | Small to medium parts, simple shapes | Flat or slightly curved parts, simple geometry |

| Cost Considerations | Lower tooling and maintenance costs, ideal for low-medium volume | High tooling costs, expensive for low-volume production | Moderate tooling costs, faster for high-volume production | High tooling costs, ideal for high-volume runs |

| Material Versatility | Wide range of materials (PE, PP, PVC, etc.) | Variety of materials but struggles with large or hollow parts | Limited to PE, PP materials | Best for thermoset materials, less material variety |

| Production Speed | Slower production cycles | Faster production, suitable for high volume | Faster production for high volumes | Moderate production speed, suited for large production runs |

| Wall Thickness Consistency | Uniform wall thickness | Varies, especially for large parts | Variable, can affect structural integrity in large parts | Consistent thickness in rigid parts |

| Material Choices | Broad selection of materials for various needs | Wide range, limited by size and shape complexity | Primarily PE and PP, lacks variety for heavy-duty parts | Limited to thermoset materials, less flexibility |

| Cost & Speed | Lower upfront tooling costs, slower cycles | Faster production, higher tooling costs | Faster production for high volume, higher tooling costs for large parts | High tooling costs, suited for high-volume parts |

To ensure consistent performance and surface quality, JaiRaj Group uses rotomolding for large, durable automotive components such as fuel tanks and protective enclosures, using advanced rotational molding techniques.

Suggested Read: Overmolding Guide: Process, Design, and Importance

Why Rotomolded Plastic Is a Great Choice?

Rotomolded plastic allows manufacturers to create high-performance, long-lasting components. It keeps tooling costs low and offers greater freedom in design.

Here’s why rotomolded plastic is a smart choice for forward-thinking manufacturers.

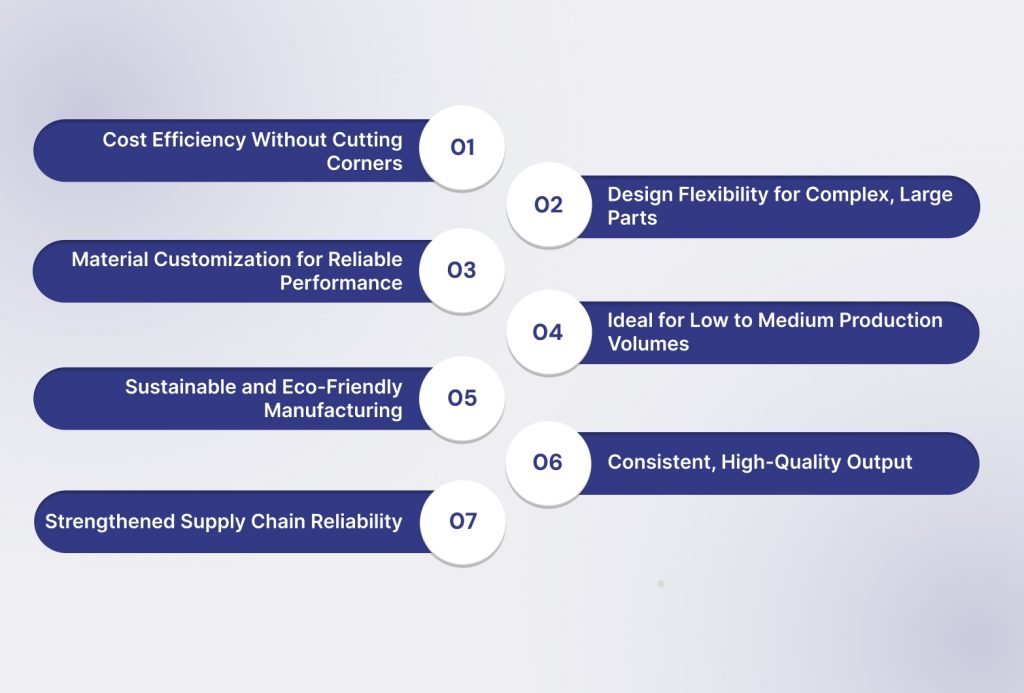

Cost Efficiency Without Cutting Corners

Rotomolding is a cost-effective way to produce durable, high-quality parts, especially for medium and low-volume runs. It helps to maintain quality while keeping costs in check.

- Lower Tooling and Maintenance Costs: Unlike injection molding, rotomolding doesn’t require expensive, complex molds. The tooling is simpler and more affordable, resulting in reduced upfront costs and lower maintenance over time.

- Less Material Waste: The process utilizes plastic resin efficiently, resulting in minimal to no scrap. This lowers material costs and supports sustainability goals by reducing waste during production.

Design Flexibility for Complex, Large Parts

Rotomolding shines when it comes to creating large or complex parts that demand strength and precision. For industries like automotive and heavy machinery, this flexibility is a major advantage.

- Freedom in Design: Manufacturers can create hollow, smooth parts in almost any shape or size, something that’s difficult or costly with other molding methods.

- Stronger, Seamless Parts: Since rotomolded components are made without joints or welds, they’re tougher and less likely to fail under stress. This makes them ideal for applications such as fuel tanks, bumpers, or protective enclosures.

Material Customization for Reliable Performance

Rotomolding provides the flexibility to select and tailor materials according to specific performance requirements. Whether you need impact strength, UV protection, or chemical resistance, the process can deliver.

- Multiple Material Options: Polyethylene (PE), polypropylene (PP), and PVC can be customized for different applications, from UV-resistant outdoor gear to impact-resistant automotive parts.

- Built for Durability: Rotomolded materials are strong, long-lasting, and weather-resistant. In tough environments like defense or industrial settings, they help reduce replacements and maintenance costs.

Ideal for Low to Medium Production Volumes

While rotomolding takes longer per cycle than injection molding, it’s far more efficient for medium- or low-volume production. It allows OEMs to respond quickly to market changes without major retooling expenses.

- Faster Turnaround on Custom Orders: The simplicity of the process makes it easier to launch new designs or modify existing ones without long delays.

- Flexible Production Runs: Adjusting part designs or materials is easy and cost-effective, helping manufacturers stay agile when production needs shift.

Sustainable and Eco-Friendly Manufacturing

Rotomolding supports sustainability by minimizing waste and using recyclable materials. It’s an environmentally friendly choice that also reduces long-term production costs.

- Minimal Waste Generation: The process produces almost no scrap, resulting in fewer raw materials wasted and lower overall production costs.

- Recyclable Resins: Many rotomolding materials are recyclable, helping companies align with eco-friendly practices and sustainability certifications.

Consistent, High-Quality Output

Rotomolding delivers uniform parts with consistent wall thickness and strength. This reliability makes it ideal for applications where quality and precision can’t be compromised.

- Even Wall Thickness: The process evenly distributes material during rotation, producing structurally sound parts free of weak points.

- Dependable Quality Control: Rotomolded products consistently meet industry standards, ensuring you get the same high quality with every production batch.

Strengthened Supply Chain Reliability

Rotomolding simplifies manufacturing and stabilizes the supply chain. It enables on-time production and flexible order adjustments, both of which are critical.

- Steady, Predictable Output: The process is efficient and dependable, helping manufacturers meet deadlines without compromising on quality.

- On-Demand Production: Rotomolding supports just-in-time manufacturing, reducing storage costs and keeping production schedules agile to match changing demands.

Once you know why rotomolded plastic is a great choice, it helps to understand how the process behind it actually works.

How Does the Plastic Rotomolding Process Work?

Rotomolding is a flexible, cost-effective way to produce strong, hollow plastic parts. It offers a reliable solution for producing large, complex, high-performance components used across industries.

Let’s look at how the rotomolding process works and why it’s so valuable in these sectors.

The Basics of Rotomolding

The process starts by adding a measured amount of plastic resin into a mold. Once sealed, the mold is heated and rotated on two perpendicular axes to distribute the resin evenly.

This steady rotation helps the resin spread evenly across the inside surface, creating a uniform, hollow part with consistent wall thickness. After cooling, the mold is opened, and the finished part is removed. ready for the next stage.

Material Selection and Resin Types

Rotomolding is adaptable when it comes to material choice. Common resins used include polyethylene (PE), polypropylene (PP), and PVC. Each material brings its own strengths, enabling customization of parts for different uses and performance needs.

Mold Design and Preparation

The molds used in rotomolding are usually made of aluminum, steel, or cast iron, depending on the size and complexity of the part. They’re built to be tough and long-lasting, capable of handling repeated heating and cooling cycles. Before use, molds are preheated to ensure even material distribution.

Heating and Rotating

After loading the resin, the mold is sealed and placed inside an oven or heated chamber. As it rotates on two axes, the heat melts the resin, allowing it to evenly coat the inner surface of the mold. This step defines the shape and wall thickness of the final part.

Cooling and Part Removal

Once the plastic has fully melted and formed, the mold is cooled down. Cooling solidifies the material, locking in its final shape. When the part is fully set, the mold is opened, and the piece is removed as strong, seamless, and ready for use.

Post-Processing and Quality Control

After demolding, each part goes through trimming, finishing, and other post-processing steps. It is then quality-checked for performance, strength, and compliance before being shipped to customers.

Cost and Production Efficiency

One of the biggest advantages of rotomolding is its cost efficiency, especially for small to medium production runs. Tooling costs are much lower than in injection molding, making it ideal for OEMs that need high-quality, durable parts without heavy upfront investment.

Once you understand how the rotomolding process works, the next step is to manage risks and choose a reliable supplier to achieve the best results.

Also Read: Injection Mold Components: Understanding the Parts

Practical Tips to Manage Risk and Select the Best Rotomolding Supplier

When choosing a rotomolding supplier, you need to think beyond just cost. The right partner should help manage risk by delivering high-quality parts, meeting deadlines, and keeping production smooth and efficient. Here are some practical tips to help you pick the right supplier while minimizing potential risks.

Assess Supplier Expertise and Industry Experience

Look for suppliers with solid experience in your specific industry. A supplier who understands your sector’s technical demands and compliance standards is more likely to deliver parts that perform reliably. Ask for examples of past projects or case studies similar to yours.

Evaluate Production Capabilities and Flexibility

Make sure your supplier can handle your required production volume and scale when needed. Ask if the supplier can easily adjust designs or materials during production. A flexible partner can adapt quickly to design updates or new material requirements without causing major delays.

Inspect Quality Assurance Practices

Choose a supplier with strong quality control systems in place. They should have testing protocols for wall thickness, dimensional accuracy, and durability. Look for certifications such as ISO 9001 or IATF 16949, which indicate adherence to consistent quality standards.

Review Material Selection and Performance Guarantees

Check whether the supplier offers a variety of materials suited to your application, such as HDPE, PP, or PVC, each with properties like UV resistance, chemical resistance, or impact strength. Ask whether they provide performance guarantees.

Assess Lead Times and Production Capacity

Confirm that the supplier’s lead times fit your project schedule. The supplier should be able to handle your order volume without compromising on quality or delivery speed, even during busy periods.

Evaluate Financial Stability

Partner with financially stable suppliers who can consistently invest in technology, tooling, and materials. For long-term partnerships, ask for financial references or proof of stability.

Check for Certifications and Compliance

Look for certifications such as ISO 9001, ISO 14001, or IATF 16949. These show the supplier’s commitment to quality management and environmental standards. Ensure they comply with the regulations specific to your industry.

Review Communication and Responsiveness

Choose a supplier who values open and transparent communication. Set up direct communication with key contacts at the supplier’s end. Quick and clear communication can make all the difference when issues arise or timelines shift.

Must Read: Automotive Injection Molding Guide for Cost Optimization and Supplier Strategy

Partner with JaiRaj Group for Precision Plastic Solutions

Choosing the right plastic materials is crucial to creating strong, reliable, and cost-effective automotive parts. At JaiRaj Group, we focus on delivering precision-engineered plastic components that meet the demanding requirements of the automotive, mobility, and heavy equipment industries.

Our advanced facilities in Faridabad, Rudrapur, Aurangabad, Manesar, and Sanand are equipped to produce high-quality components that boost performance, durability, and efficiency in modern vehicle manufacturing.

Why choose Jairaj Group?

- Plastic Bellows and Struts: Built from durable, flexible materials, these parts help control vibration and keep out dust, which are essential for vehicles and industrial machines that experience constant movement and pressure.

- Brake & Accelerator Pedals: Designed for strength and accuracy, these pedals ensure dependable performance even in challenging conditions, making them ideal for mobility systems.

- Braking System Components: Made through precision injection molding, these components meet strict industry standards for heat resistance and toughness, ensuring they withstand stress.

- Roto-Moulded Components: We produce strong, long-lasting components through rotational molding, a process that delivers excellent structural integrity for engineering and automotive applications.

- Precision Components from Advanced Polymers: Using materials such as PEEK and polycarbonate, we create parts that withstand extreme temperatures and harsh environments, ideal for systems that require long-lasting, high-performance solutions.

Partner with JaiRaj Group for reliable, high-quality plastic components that bring together performance, durability, and cost-efficiency. With over 35 years of experience, we continue to support the automotive industry with materials that meet the highest standards.

Final Thoughts

Rotomolded plastic offers a smart and cost-effective way to create durable, high-performance parts. It’s ideal for large, complex, and hollow components, making it a strong fit for industries like automotive, heavy equipment, and defense.

With lower tooling and maintenance costs and flexible material options, rotomolding helps manufacturers improve efficiency and reliability. At JaiRaj Group, we design and produce precision-engineered plastic solutions for the automotive industry using advanced injection and extrusion molding technologies.

Our products, including brake system components and high-performance parts made from PEEK and polycarbonate, are built to meet the demanding needs of modern vehicles, ensuring strength, durability, and reliable performance.

Reach out to JaiRaj Group for high-quality plastic components customized for your automotive manufacturing needs. We help you achieve cost efficiency and design flexibility while maintaining top-level performance and quality.

FAQs

1. What is the environmental impact of rotomolding?

Rotomolding is considered quite eco-friendly since it produces very little waste. The materials used are often recyclable, and the process itself doesn’t need heavy or energy-hungry tooling. Many rotomolded plastics, like polyethylene, can also be recycled at the end of their use, making the entire process more sustainable.

2. Can rotomolding be used to make clear plastic parts?

Yes, it can, but it depends on the resin used. Materials like polycarbonate or acrylic can be chosen to make clear or see-through parts. However, rotomolding is more commonly used for opaque products because achieving full clarity can be tricky.

3. How does rotomolding compare to 3D printing for complex parts?

Rotomolding works best for making large, hollow parts in larger quantities, while 3D printing shines when creating small, detailed, or custom pieces. Rotomolding is more efficient and durable for mass production, whereas 3D printing is perfect for quick prototypes and one-off designs.

4. Can rotomolded parts handle high pressure?

Rotomolded parts are great for low to medium-pressure applications, and their strength can be improved with reinforcements. But for high-pressure systems like hydraulics, tougher materials such as metal or composites are usually a better choice.

5. How does rotomolding support product customization?

Rotomolding gives manufacturers a great deal of design freedom. The molds can be adjusted easily to change the shape, size, or color of a product, making it a great choice for customized parts that need to meet specific requirements.