Selecting the right Original Equipment Manufacturer (OEM) plastic supplier is critical, directly impacting your product quality and time-to-market. Tier 1 suppliers frequently face high raw material price volatility and struggle with inconsistent quality control across smaller manufacturers, leading to costly production delays and high warranty claims.

The stakes are high: the overall India plastics market is expected to reach ₹6.84 lakh crores ($77 billion) in 2033, driven heavily by automotive lightweighting and electronics. Securing a reliable, certified manufacturing partner is essential to mitigate operational risks and maintain competitive cost structures.

This blog evaluates the top OEM plastic manufacturers in India based on quality systems, technical capabilities, and proven track records to provide a clear, actionable procurement guide.

Key Takeaways

- Supplier is a Strategic Partner: An OEM plastic supplier provides critical DFM (Design for Manufacturability) and engineering support, going beyond simple moulding.

- Evaluation is Crucial: Selecting a partner requires rigorous assessment of their Technical Capability, Quality Certifications (ISO/IATF), and Production Capacity.

- Focus on TLC & IP: Prioritise Total Lifecycle Cost (TLC) over initial quotes and ensure robust IP Protection and tool ownership agreements.

- Market Leaders Set the Bar: Jairaj Group is highlighted as a benchmark for high-volume, certified manufacturing with end-to-end DFM support.

The Strategic Value of an OEM Plastic Manufacturer

An OEM plastic supplier is not merely a vendor; they are a Tier 1 or Tier 2 engineering and quality assurance extension of your own operations. Their function goes far beyond simply moulding parts. It is about translating complex digital specifications into physical, scalable reality while mitigating systemic risk.

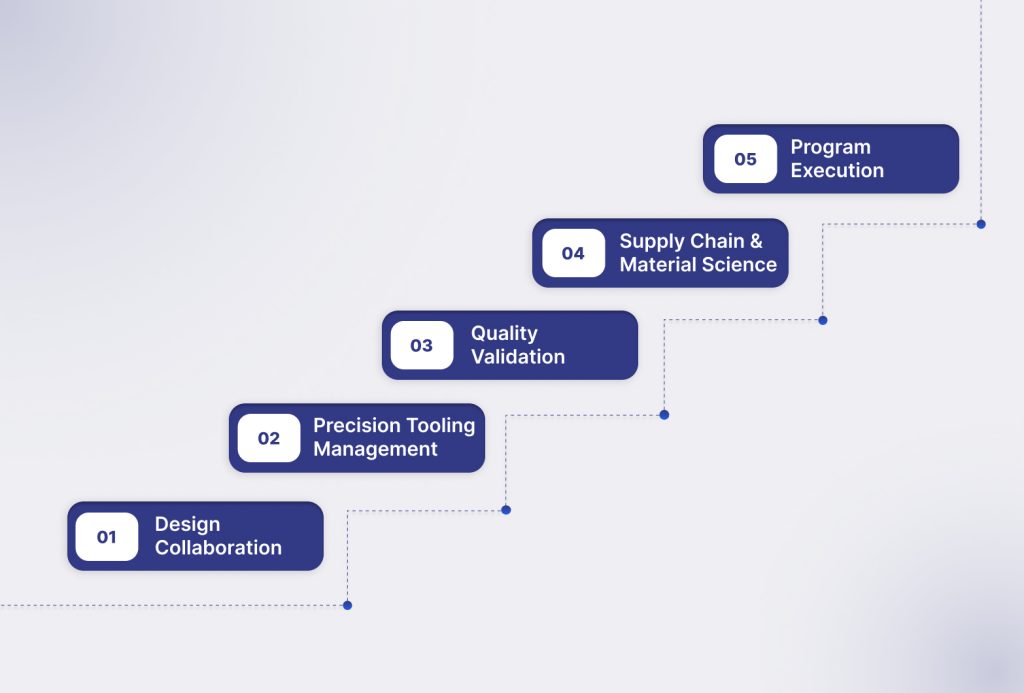

- Design Collaboration & Validation: They employ Design for Manufacturability (DFM) expertise, working with your R&D teams to identify potential production issues and high-risk geometries before tool cutting. This proactive approach saves months of rework and millions in wasted tooling capital.

- Precision Tooling Management: They manage the investment in complex, high-cavitation, and long-life moulds. This includes rigorous tool steel selection, maintenance schedules, and lifecycle planning to ensure the tool’s performance guarantees part consistency and maximum shot capacity over the full program duration.

- Process and Quality Validation: They are responsible for implementing certified Quality Management Systems (ISO 9001, IATF 16949, etc.) and executing formal approval protocols like PPAP (Production Part Approval Process). This step is the formal guarantee that the part meets every specified tolerance, material property, and performance criterion before mass production begins.

- Supply Chain & Material Science: They manage the sourcing, inventory, and traceability of engineering-grade resins, additives, and colourants. This requires deep knowledge of material properties, regulatory status, and sourcing redundancy to mitigate raw material price volatility and supply bottlenecks.

- Logistics and Program Execution: They synchronise their manufacturing schedule with your final assembly line’s demands, often utilising Just-in-Time (JIT) or specific buffer-stock agreements. This logistics competency is crucial for preventing expensive line stoppages and ensuring stable program continuity.

Having established the strategic necessity of a reliable partner, let’s look at the market leaders who meet these demanding criteria.

Also Read: 5 Best Plastics for Durable Outdoor Use

Top 5 OEM Plastic Manufacturers in India

Given the high-stakes requirements for quality control, certification, and global supply chain integration, it is essential to partner only with organisations that demonstrate proven scale. The following list highlights five of India’s most capable OEM-focused plastic manufacturers:

1. Jairaj Group

Jairaj Group is a leading OEM plastic manufacturer specialising in precision-engineered components for demanding sectors. With its decades of expertise in polymer science and advanced moulding techniques, the company provides a wide array of plastic parts, assemblies, and systems. Its solutions are designed to meet stringent quality and performance standards for high-volume manufacturing.

- Established: 1985

- Location: Gurugram with multi-site facilities including Rudrapur, Aurangabad, and Sanand.

- Certifications: ISO 9001:2015, IATF 16949

- Industries Served: Automotive, Industrial Machinery, Aerospace, Solar, Consumer Appliances, Defence.

Key Features

- Advanced Manufacturing Technologies: Jairaj Group utilises a diverse range of processes, including Plastic Injection Moulding, Blow Moulding, Rotational Moulding, and Extrusion. This multi-technology capability allows OEMs to consolidate complex supply needs, optimising production logistics and reducing the risk associated with single-process constraints.

- Material Choice and Expertise: Expertise in engineering polymers like TPE/TPV, PBT Arnite, and ABS allows for selecting materials that directly impact a product’s lifecycle. This ensures components are engineered not just for function, but for cost-efficiency (by reducing material waste), durability (through resistance to chemical and thermal stress), and compliance with industry-specific, demanding standards.

- Quality Assurance Capabilities: Maintaining the IATF 16949 certification is crucial for automotive and other highly regulated OEM clients. This structured quality system ensures traceability of every part, precise dimensional stability, and consistent part quality across high-volume production, directly mitigating product failure risks and warranty costs for the OEM.

- End-to-End Support and Tooling: The company offers comprehensive support from early DFM consultation through in-house tool design and production scaling. This integration accelerates the product launch cycle, minimises expensive mould rework, and ensures the final component is perfectly optimised for the OEM’s assembly line requirements.

Core Products

- Plastic Bellows & Struts

- Brake & Accelerator Pedal Assemblies

- Mobility Plastic Base Seating Solutions

- Interior & Exterior Accessories and Components

- Precision Components from Advance Polymers

What Makes Jairaj Group an Expert OEM Plastic Manufacturer?

Jairaj Group stands out by coupling decades of high-volume manufacturing experience with strict IATF 16949 compliance, ensuring components are not only produced at scale but also guaranteed for the long-term reliability and low Total Cost of Ownership demanded by global OEMs.

2. Ravi Plast Mould

Ravi Plast Mould is a private limited company that specialises in manufacturing high-precision engineering plastic components. They provide a comprehensive, single-source solution, managing projects from the initial product design phase through to final moulding and post-moulding processes.

- Established: 1980

- Location: Ahmedabad, Gujarat

- Unique Feature: Offers an ISO 9001:2015 certified one-stop solution for converting metal or wooden parts into precision engineering plastic components.

- Key Products and Services: Custom injection moulding, high-precision engineering plastic parts, and textile machinery components.

- Industries Served: Industrial machinery, automotive, textile, construction, and oil & gas.

Also Read: 7 Common Types of Plastics Used in Automotive Components

3. SSI Moulds (Sunshine Industries Ltd)

SSI Moulds is a well-established manufacturer and supplier specialising in plastic injection moulding, thermoforming, and contract manufacturing services. Their strategic focus is on providing products with global quality at a cost-effective price point.

- Established: 1992

- Location: New Delhi (Operates in the domestic and international market).

- Unique Feature: Excels in low-cost manufacturing alongside high quality, offering contract manufacturing and custom product development as core services.

- Key Products and Services: Plastic components for lighting and switchgear, home appliance fittings, and furniture hardware.

- Industries Served: Automotive, consumer electronics, home appliances, and furniture.

4. Vidhata Plastics

Vidhata Plastics is a leading plastic parts and mould manufacturer recognised for its extensive experience and sophisticated in-house tooling capabilities. They focus on delivering both complex injection moulds and precision plastic parts across diverse high-tolerance industries.

- Established: 1991

- Location: Hyderabad, Telangana

- Unique Feature: Strong expertise in manufacturing complex, high-cavitation injection moulds and managing sophisticated material flow for flawless precision parts.

- Key Products and Services: Precision plastic components, tool and mould making, overmoulding, and insert moulding techniques.

- Industries Served: Medical devices, automotive, consumer goods, and electronics.

5. R. D. Mould & Industry

R. D. Mould & Industry is an injection mould manufacturer known for its specialised focus on moulds for disposable items and household goods. They provide both standard and customised mould designs with a strong emphasis on tooling for high-volume production.

- Established: 2002

- Location: Ahmedabad, Gujarat

- Unique Feature: Recognised for specialising in the design and production of high-volume, cost-effective tooling for consumer and disposable plastic products, which positions them as a leading supplier in this competitive, price-sensitive segment.

- Key Products and Services: Moulds for disposable cutlery (spoons, forks), food containers, kitchenware like basins and cups, and small plastic toys.

- Industries Served: Household goods, packaging, food service, and kitchenware manufacturers.

With an understanding of the key players and their specialisations, we can now establish the evaluation criteria necessary for an OEM to select the optimal plastic manufacturer for their specific needs.

How to Choose the Right OEM Plastic Manufacturer?

To successfully outsource plastic component manufacturing, an OEM must move beyond simple quotations and conduct a thorough due diligence process. The right partner should function as an extension of your own engineering team.

Here are the critical evaluation criteria for selecting an optimal OEM plastic manufacturer:

1. Define and Align Project Needs

Clearly define product specifications, part complexity, annual volume forecasts, required tolerances, and crucial end-use environment (e.g., temperature, chemical exposure).

- Material Expertise: Confirm their deep experience with the specific resins (e.g., PE, PC, ABS, specialised engineering plastics) that meet your product’s performance needs.

- Design for Manufacturability (DFM): Evaluate their ability to provide proactive design feedback that reduces part cost, improves moldability, and enhances component performance before tool construction begins.

Also Read: Polypropylene vs ABS: Choosing the Right Plastic

2. Technical Expertise and Capability

Assess the range of plastic manufacturing processes they offer (injection moulding, blow moulding, thermoforming, etc.) and ensure they match your product’s requirements.

- Tooling/Mould Capabilities: Verify if they design and maintain moulds in-house. In-house tooling control often results in faster mould repairs, lower long-term costs, and better quality control.

- Advanced Machinery: Check for modern, well-maintained equipment (e.g., press tonnage, robotics, process monitoring) that can consistently handle the required precision and volume.

3. Quality and Capacity Assurance

Look for recognised certifications like ISO 9001 (general quality) or ISO 13485 (medical), demonstrating a commitment to repeatable, high-standard processes.

- Capacity and Redundancy: Confirm they have sufficient machine hours and a robust supply chain to meet your peak production demands and offer scalability without incurring delays.

- Quality Control Procedures: Inquire about their inspection plan (e.g., First Article Inspection, Statistical Process Control (SPC)), testing capabilities, and their process for tracking and resolving non-conforming parts.

Also Read: Plastic Texturing Techniques for Parts: A Strategic Guide for Decision-Makers

4. Supply Chain, Finance, and Partnership

Evaluate their track record for on-time delivery (OTD) and their logistics network for getting parts to your assembly location efficiently.

- Financial Stability: Conduct due diligence on their financial health to ensure they are a stable, long-term partner capable of sustaining operations and making future investments.

- Value-Added Services: Look for supplementary services like assembly, sonic welding, finishing, printing, or custom packaging, which can streamline your own operations and reduce total costs.

- Intellectual Property (IP) Protection: Ensure they have robust security protocols and are willing to sign non-disclosure and IP agreements to safeguard your proprietary designs and tooling.

Jairaj Group, with its decades of industry specialisation and proven capacity for end-to-end DFM support, stands as a benchmark partner for complex OEM projects.

Conclusion

The journey from component design to mass production hinges on a single, critical decision: the choice of your OEM plastic manufacturer. Do not merely seek the lowest bidder; seek the manufacturer whose technical depth, certified quality, and robust supply chain capacity align perfectly with your product’s long-term demands for compliance and resilience.

Adopting the stringent evaluation criteria outlined transforms supplier selection into a strategic advantage. It secures a partner who guarantees consistent quality and safeguards your product’s success, ultimately impacting your market position, cost-efficiency, and brand integrity.

Contact Jairaj Group to schedule a personalised review of your component design or arrange a facility visit to conduct your full supplier evaluation and witness their advanced quality control processes firsthand.

FAQs

1. How do I weigh the cost of a high-cavitation mould versus the part price?

Focus on the Total Lifecycle Cost (TLC). A high-cavitation (more expensive) mould delivers a significantly lower piece part cost, providing greater savings over high-volume, long-term production runs.

2. What key certifications should I look for beyond basic ISO 9001?

Look for industry-specific compliance like IATF 16949 (Automotive), ISO 13485 (Medical), or AS9100 (Aerospace) to ensure adherence to sector-specific quality and safety standards.

3. Is it better to choose a supplier that owns my mould or one where I retain ownership?

OEMs should always retain ownership of the mould and tooling to maintain full control over production changes, quality standards, and the flexibility to switch manufacturers if necessary.

4. What is the quickest way to assess a manufacturer’s commitment to process efficiency?

Ask about their application of Design for Manufacturing (DFM) principles and their use of automation, which directly reduces cycle times, minimises scrap, and lowers unit cost.

5. How can I ensure my product’s long-term supply chain resilience with one supplier?

Demand a clear plan for Preventative Maintenance on the tooling and inquire about their raw material dual-sourcing strategy to mitigate market price volatility and supply disruptions.