Thermoforming is a key manufacturing method that transforms plastic sheets into precise, functional components across industries such as packaging, automotive, medical devices, and consumer goods, combining speed, efficiency, and versatility.

Success depends on using the right materials, precise tooling, and controlled processes to ensure cost-effective, high-quality, and reliable production for OEMs and Tier-1 suppliers.

This guide covers the thermoforming process, materials, applications, and emerging technologies, helping manufacturers and procurement teams make informed, cost-effective decisions.

Key Takeaways:

A process that heats plastic sheets and shapes them over molds to produce precise, durable, and lightweight components.

Involves material selection, heating, forming, controlled cooling, trimming, and inspection to ensure consistent quality and functionality.

Widely used in automotive, packaging, medical devices, electronics, and consumer goods for parts that require strength, aesthetics, and precision.

Enables rapid, cost-effective mold production, faster prototyping, and easy iteration of complex designs before full-scale manufacturing.

Reduces tooling costs, accelerates time-to-market, allows flexible designs, ensures reliable quality, and strengthens supply chain stability.

Before we explore the key factors, it’s important to understand the fundamentals of thermoforming and why it has become a critical process across industries.

What is Thermoforming?

Thermoforming is a manufacturing process that heats plastic sheets until they are pliable and shapes them over a mold. Once cooled, the plastic retains the mold’s form, producing precise and functional components.

This method is widely used across automotive, packaging, medical devices, aerospace, and consumer goods.

Manufacturers rely on products like Brake & Accelerator Pedals, Plastic Bellows & Struts, and Mobility Plastic Base Seating Solutions to achieve high-quality results. Success depends on using the right materials, precise tooling, and controlled processes to ensure cost-effective, durable, and reliable production for OEMs and Tier-1 suppliers.

With these capabilities in mind, it is clear why thermoforming has become a critical process for modern manufacturing.

Importance of Thermoforming in Manufacturing

Thermoformed plastics are influenced by several key factors that directly impact cost, quality, and program success. These factors make thermoforming a business-critical choice for OEMs and Tier-1 suppliers:

Material efficiency and lightweighting: Thermoforming reduces weight and improves efficiency, producing large, strong components for automotive, aerospace, and industrial applications.

Cost predictability and tooling flexibility: Tooling is faster and cheaper than many processes, but material choice, trimming, and finishing still affect total costs.

Process consistency and quality control: Advanced equipment ensures precise temperature control and forming, reducing scrap and maintaining tight tolerances.

Design flexibility and competitive advantage: Supports complex shapes and functional features, delivering high-quality components for automotive, medical, and packaging applications.

For executives, the focus is not only on understanding thermoforming but on using it to control costs, maintain quality, and ensure supply chain stability where delays or defects carry financial risk.

Also Read: What is Plastic Welding?

Equipment and Tooling Used in Thermoforming

The performance and quality of thermoformed parts rely heavily on the right equipment and tooling. From industrial-scale production to prototype setups, each choice affects precision, efficiency, and overall cost.

Below is an overview of the critical equipment and tooling considerations for thermoforming:

| Category | Key Points | Examples |

|---|---|---|

| Equipment Type | Machines vary by production scale | Industrial machines for mass production, desktop/DIY setups for prototypes |

| Specifications | Affect part quality and efficiency | Forming area, sheet thickness, depth, clamping force, heating type |

| Tooling / Molds | Determines part shape, finish, and precision | CNC-machined molds for accuracy, 3D-printed molds for prototyping, aluminum or steel molds for durability |

| Maintenance | Ensures consistent quality and prevents downtime | Mold cleaning, wear checks, sensor calibration |

Understanding the Thermoforming Process: Key Steps

Thermoforming transforms plastic sheets into precise, functional components used across industries such as automotive, packaging, and medical devices. Each stage of the process, from selecting the right material to final inspection, directly affects part quality, production efficiency, and cost.

The following sections break down the key stages of thermoforming.

Step 1: Material Selection

Material choice drives the performance, durability, and manufacturability of thermoformed components. Common options include PP, PET, PS, ABS, PVC, and PC, chosen based on strength, flexibility, and chemical resistance.

To provide a practical view, the table below summarizes widely used thermoforming materials, highlighting their properties and typical applications:

| Material | Key Properties | Typical Applications |

|---|---|---|

| Polypropylene (PP) | Lightweight, flexible, chemical-resistant | Food containers, automotive trims, industrial housings |

| Polystyrene (PS) | Easy to mold, rigid, economical | Packaging trays, disposable containers, consumer goods |

| PET | Durable, food-safe, recyclable | Beverage trays, clamshell packaging, medical trays |

| LDPE & HDPE | Moisture and impact resistant | Industrial containers, packaging films, protective covers |

Certain applications demand high-performance plastics with specific thermal, chemical, or aesthetic properties.

The following materials are commonly used in advanced thermoforming:

| Material | Key Properties | Typical Applications |

|---|---|---|

| PVC | Strong, versatile, weather-resistant | Industrial panels, signage, piping covers |

| Polycarbonate (PC) | High impact and heat resistance | Automotive headlamp covers, protective shields |

| PMMA (Acrylic) | Transparent, UV- and weather-resistant | Lenses, display panels, architectural glazing |

| ABS | Tough, dimensionally stable | Electronics housings, automotive interiors, consumer appliances |

Challenges:

Brittle, heat-sensitive, or incompatible materials can warp, crack, or show surface defects.

Material inconsistency or poor supply can lead to production delays or quality variation.

Best Practices:

Match materials to environmental conditions and operational requirements.

Consider recyclability and long-term availability from reliable suppliers.

Conduct thermal and chemical testing before full-scale production.

Step 2: Sheet Heating

Once the material is selected, it is heated until pliable. Uniform heating ensures the sheet can form accurately without thinning or tearing.

Challenges:

Uneven heating can create bubbles, weak spots, or thinning.

Overheating may degrade the material or change its properties.

Best Practices:

Use precise temperature controls and continuous monitoring.

Adjust heating duration based on sheet thickness.

Employ preheating zones for larger or thicker sheets to ensure even pliability.

Example: Thick HDPE industrial containers require longer, carefully controlled heating to avoid thin spots or warping during forming.

Step 3: Forming Over the Mold

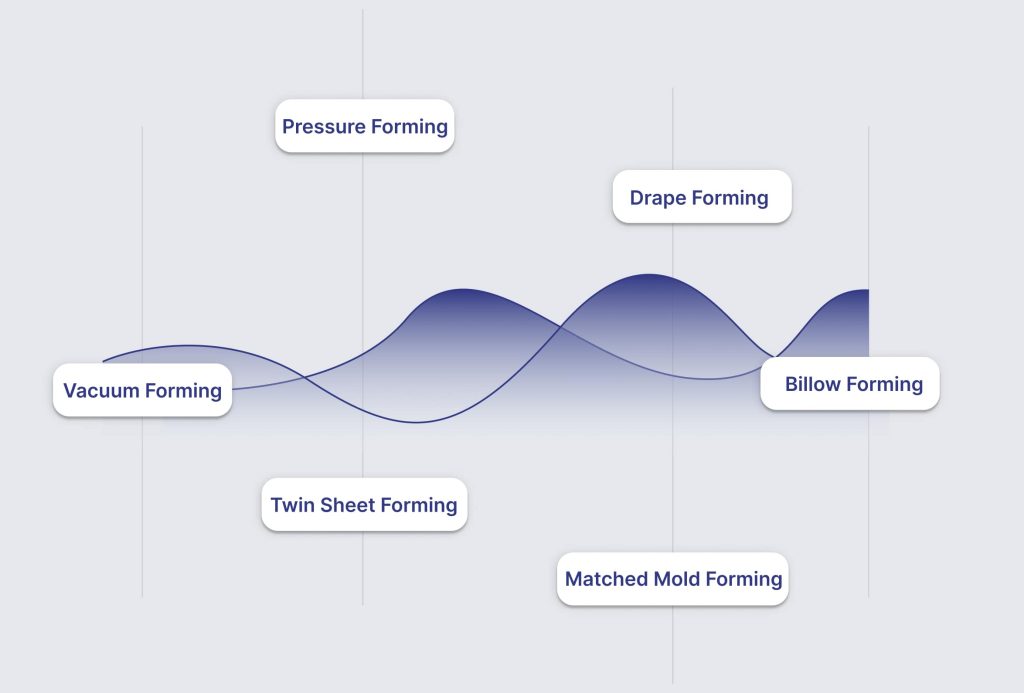

Different thermoforming techniques suit varying part complexity and production requirements. The heated sheet is shaped using a method suited to the part’s complexity and performance needs:

Vacuum Forming: Pulls the sheet over a mold; ideal for packaging and simple product parts.

Pressure Forming: Adds pressure for sharper textures and fine details; used for automotive panels and protective cases.

Drape Forming: Drapes the sheet over the mold; balances precision and cost.

Billow Forming: Uses air pressure for rounded or domed shapes; suitable for light covers and decorative panels.

Matched Mold Forming: Presses sheet between two molds for high-detail components; requires higher tooling investment.

Twin Sheet Forming: Bonds two sheets to create strong, double-walled components for tanks, containers, and protective casings.

Challenges:

Incorrect pressure, timing, or mold alignment can cause stretching, warping, or incomplete replication.

Complex geometries may trap air, causing surface defects.

Best Practices:

Select forming technique based on part complexity and production volume.

Apply mold surface coatings for smooth finish and easier release.

Run pilot trials to optimize forming parameters.

Example: Twin sheet forming is used for large automotive fuel tanks, combining strength and leak resistance in one component.

Also Read: Plastic Injection Molding: Precision Thermoplastic Components

Step 4: Controlled Cooling

Cooling is more than a finishing step, it determines whether a thermoformed part retains its precise geometry and structural integrity. In high-stakes industries like automotive and aerospace, uneven cooling can undermine part reliability, lead to rework, or delay production schedules.

Challenges:

Uneven cooling can cause warping, bowing, or uneven wall thickness.

Rapid cooling of heat-sensitive materials can lead to cracks, surface crazing, or internal stresses that reduce part strength.

Thick sections cool slower than thin areas, creating differential shrinkage and dimensional variation.

Best Practices:

Incorporate uniform cooling channels in molds to maintain consistent temperature distribution.

Adjust cooling time based on material type, thickness, and part geometry.

Use controlled, gradual cooling for sensitive plastics to prevent surface defects.

For critical aerospace or automotive panels, simulate cooling in CAD to predict deformation and optimize mold design.

Example: Automotive interior panels often use multi-zone cooling to prevent warping and maintain tight dimensional tolerances for snap-fit assembly.

Step 5: Trimming and Finishing

Once formed, thermoformed parts require trimming and finishing to achieve the exact dimensions, functional features, and surface quality required for assembly. For OEMs and Tier-1 suppliers, this step ensures parts meet design tolerances, improve fit, and reduce downstream assembly issues.

Challenges:

Manual trimming may create burrs, scratches, or uneven edges, compromising fit or safety.

Over-trimming or misalignment can damage structural features.

Complex parts with deep contours require specialized tools to prevent deformation.

Best Practices:

Use CNC or automated trimming for consistent, repeatable results.

Conduct in-line inspections of critical dimensions immediately after finishing.

Integrate finishing operations into the production line to minimize handling and reduce cycle time.

Apply deburring or polishing for high-visibility parts in automotive interiors or medical devices.

Example: Thermoformed protective casings for electronics often require precise CNC trimming to ensure snap-fit assembly and seamless integration with other components.

Step 6: Inspection and Quality Control

Rigorous inspection and quality control are essential to prevent subtle defects from affecting part performance, aesthetics, or regulatory compliance.

Effective quality management helps manufacturers deliver parts that meet strict industry standards while minimizing scrap and rework costs.

Challenges:

Subtle defects such as thin walls, surface pits, or micro-cracks can impact structural integrity and assembly fit.

Visual inspection alone may miss dimensional deviations in complex geometries.

Inconsistent inspection leads to rework, scrap, or field failures.

Best Practices:

Implement Statistical Process Control (SPC) to monitor key process parameters in real time.

Use non-contact measurement systems like laser scanning or 3D optical metrology for complex shapes.

Track and analyze defect data to prevent recurrence in future production runs.

Maintain inspection logs for compliance with ISO or automotive standards (IATF 16949).

Example: Medical device trays undergo 100% dimensional verification using 3D scanning to ensure sterility and assembly compatibility.

Step 7: Packaging and Distribution

Even perfectly formed parts are vulnerable if mishandled during storage or transport.

Thoughtful packaging and careful distribution protect surface finish, preserve structural integrity, and ensure components reach assembly lines in optimal condition, supporting uninterrupted production schedules.

Challenges:

Improper stacking or handling can deform thin-walled or intricate parts.

Surface scratches or abrasions reduce aesthetic quality for high-value components.

Environmental factors such as humidity or heat during transit can affect dimensional stability.

Best Practices:

Use foam inserts, vacuum trays, or molded supports to prevent movement and deformation.

Limit stacking height and weight to avoid compression damage.

Clearly label handling instructions and orientation for logistics personnel.

For automotive or aerospace components, consider climate-controlled packaging for heat-sensitive materials.

Example: Transparent polycarbonate automotive lenses are shipped in custom foam trays to prevent scratches and maintain optical clarity.

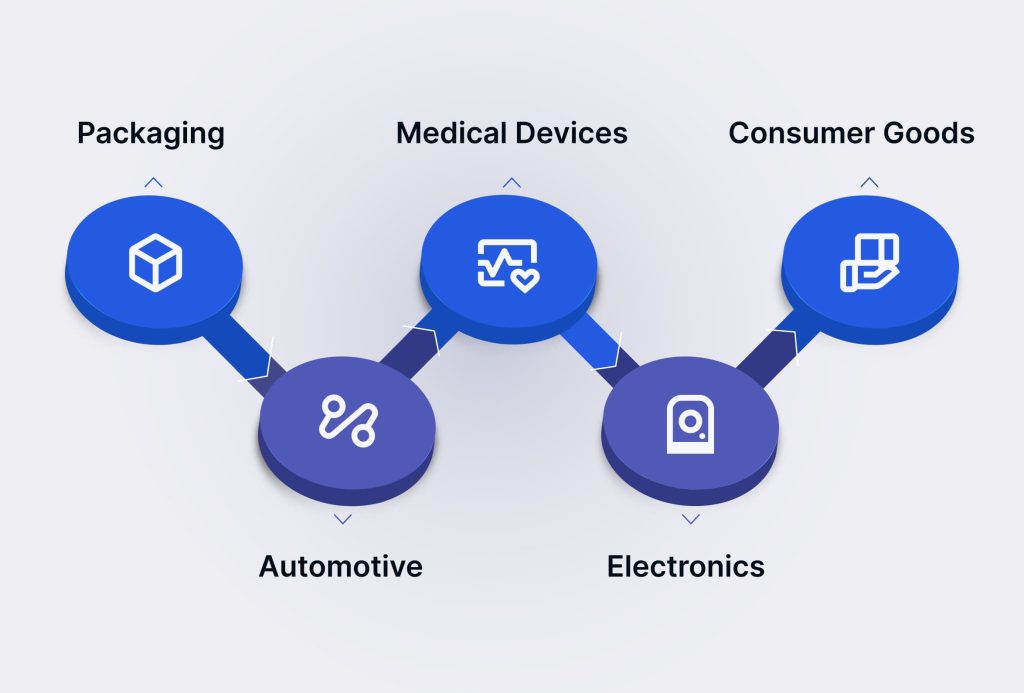

Applications of Thermoforming Across Industries

Thermoforming is a versatile manufacturing process that goes beyond simple shaping of plastics.

It enables industries to create precise, durable, lightweight, and cost-effective components at scale. Its adaptability allows companies to meet performance, regulatory, and aesthetic requirements while optimizing production efficiency.

Here’s how thermoforming drives value across major sectors:

1. Packaging

Thermoforming delivers packaging solutions that are lightweight, resilient, and visually appealing, ensuring products reach consumers safely while enhancing brand presentation.

Applications: Food trays, clamshells, blister packs, and protective shipping containers.

Key Benefits: High-volume production, consistent part quality, recyclable materials, and tailored designs to fit products perfectly.

Considerations: Dimensional stability and prevention of warping or cracking during high-speed operations.

2. Automotive

For OEMs and Tier-1 suppliers, thermoforming supports the production of components that are structurally reliable, visually premium, and lightweight, critical for performance and EV efficiency.

Applications: Dashboards, door panels, interior trims, protective covers, and EV structural panels.

Key Benefits: Allows multi-layer designs, textured surfaces, color integration, and precise snap-fit assemblies.

Considerations: Maintaining tolerance and surface quality in complex geometries and high-volume runs.

3. Medical Devices

Thermoforming ensures safe, sterilizable, and functional components, essential in medical applications where hygiene and durability are critical.

Applications: Sterilization trays, instrument housings, diagnostic components, and patient-care equipment.

Key Benefits: Smooth, cleanable surfaces; resistance to chemicals; and precise, repeatable geometries.

Considerations: Compliance with strict regulatory standards and resistance to high-temperature sterilization processes.

4. Electronics

Electronic components benefit from thermoforming’s ability to produce impact-resistant, heat-stable, and dimensionally precise housings that protect sensitive electronics.

Applications: Device casings, display covers, control panels, and appliance housings.

Key Benefits: Enhanced thermal management, structural integrity, premium finishes, and lightweight design.

Considerations: Balancing strength, heat resistance, and aesthetic quality for consumer-facing components.

5. Consumer Goods

Thermoforming empowers designers to create ergonomic, visually appealing, and durable products, enhancing user experience and market competitiveness.

Applications: Toys, sporting goods, furniture components, household items, and decorative panels.

Key Benefits: Supports intricate designs, ergonomic features, multi-color finishes, and lightweight yet durable construction.

Considerations: Ensuring structural integrity, safety, and aesthetic appeal while maintaining cost efficiency.

How Does 3D Printing Enhance Thermoforming?

Thermoforming is traditionally limited by mold lead times and tooling costs. Integrating 3D printing addresses these challenges by enabling rapid, cost-effective mold production, allowing manufacturers to move from concept to functional part faster.

Here are the key aspects of using 3D printing in thermoforming:

1. 3D Printed Molds

3D printing allows creation of molds directly from digital CAD models, reducing dependency on CNC machining or traditional fabrication.

Benefits: Shortens prototyping cycles, lowers tooling costs, and enables small-batch or customized production without large capital investment.

Applications: Custom packaging prototypes, low-volume automotive panels, medical device housings, and decorative consumer components.

2. Integrated Workflow Process:

Create the mold design digitally using CAD software.

Print the mold using suitable 3D printing material (e.g., high-temperature resin or reinforced thermoplastics).

Use the printed mold directly in the thermoforming process to shape heated plastic sheets.

Advantages: Rapid iteration of mold designs, precise reproduction of complex geometries, and the ability to test multiple variants before committing to full-scale production.

3. Combining Prototyping with Production Scalability

This integration leverages the speed and flexibility of 3D printing with the efficiency, repeatability, and cost-effectiveness of thermoforming, creating a hybrid approach that suits both prototyping and production needs.

Example: Automotive concept panels or packaging prototypes can be produced quickly for design verification, then seamlessly transitioned to standard thermoforming molds for mass production.

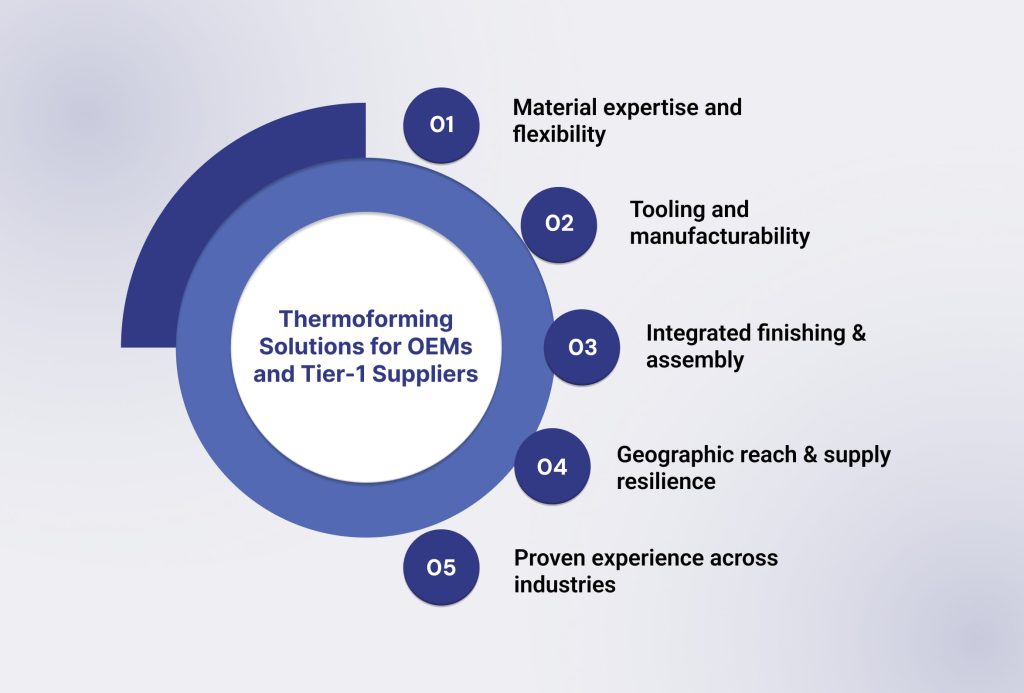

Thermoforming Solutions for OEMs and Tier-1 Suppliers

Thermoforming can help manufacturers reduce costs, speed up product launches, and improve supply chain reliability. With the right expertise, OEMs and Tier-1 suppliers can get high-quality, durable, and cost-efficient components.

JaiRaj Group has developed its thermoforming capabilities around five key areas that ensure performance and reliability:

1) Material expertise and flexibility

JaiRaj works with ABS, HIPS, PETG, polycarbonate, and multilayer sheets to achieve the right balance of strength, weight, and finish. In-house R&D quickly validates new materials, giving procurement teams options when markets change.

2) Tooling and manufacturability

Early Design for Manufacturability (DfM) reviews and precise tooling reduce warping, thinning, and defects. This approach speeds up part approval and keeps production on schedule.

3) Integrated finishing and assembly

JaiRaj provides trimming, bonding, painting, and assembly in-house. This reduces handoffs, shortens lead times, and maintains consistent quality.

4) Geographic reach and supply resilience

Facilities in Faridabad, Manesar, Aurangabad, Sanand, and Rudrapur place JaiRaj near India’s key automotive and industrial hubs. This reduces shipping costs, ensures faster delivery, and offers backup capacity during disruptions.

5) Proven experience across industries

With 35+ years of experience and certifications including IATF 16949, ISO, and CE, JaiRaj delivers thermoformed parts for:

For procurement teams, JaiRaj provides more than just thermoformed parts. It offers a reliable partnership focused on cost efficiency, supply continuity, and smooth program execution.

Conclusion

Thermoforming is no longer just a basic shaping method. It has become a strategic enabler for manufacturers managing tight launch schedules, stringent compliance standards, and complex global supply networks.

Whether it involves vacuum forming or twin-sheet forming, it affects more than product design. It directly drives speed to market, consistency in quality, and production scalability.

Organizations that integrate strong tooling strategies, structured quality systems, and early-stage design collaboration into their thermoforming programs consistently gain three key advantages:

Stable production costs by preventing hidden expenses from scrap, rework, and inefficient logistics.

Accelerated market entry through supplier-driven design validation and faster approval cycles.

Robust supply continuity to withstand material price swings and regional manufacturing challenges.

If you are developing a new thermoformed component or transitioning existing parts, partner with Jairaj Group for a Design for Manufacturability (DfM) consultation or a visit to our Manesar, Sanand, or Aurangabad plants.

Reach out to Jairaj Group to explore how we can support your requirements.

FAQs

1. What drives the cost of thermoformed components?

Tooling complexity, material choice, sheet thickness, cycle time, and production volume influence costs. Trimming, assembly, and finishing steps can add further expense.

2. How does tooling design affect project timelines?

Well-designed tooling ensures consistent quality and faster approvals. Weak tooling causes defects, rework, and delays in production schedules.

3. When is thermoforming the right choice?

Thermoforming works best for large, lightweight parts with moderate complexity. It is suitable when quick turnaround and lower initial tooling investment are priorities.

4. What should OEMs look for in a thermoforming supplier?

A reliable supplier should have strong tooling capability, in-house finishing, proven quality systems, and experience with regulated industries such as automotive or aerospace.

5. How does thermoforming support supply chain resilience?

Thermoforming allows faster tooling development, localized production, and quick capacity adjustments. This flexibility helps prevent supply disruptions.

6. How should OEMs evaluate total cost of ownership?

They should include tooling, labor, scrap, logistics, and compliance costs, not just part price. This approach improves budgeting and long-term value.