Machining and Turning

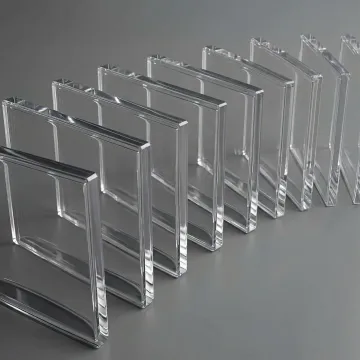

Precision CNC machining and turning operations for creating accurate railroad skylight frames, brackets, and mounting components with tight tolerances.

Specialized precision CNC machining services for durable railroad skylight components. Our advanced polymer expertise and state-of-the-art machinery deliver tight-tolerance, weather-resistant plastic parts that meet railway industry standards for safety, clarity, and structural integrity in demanding transit environments.

Complete precision machining solutions for railroad skylight components using advanced CNC technology.

Precision CNC machining and turning operations for creating accurate railroad skylight frames, brackets, and mounting components with tight tolerances.

Manufacturing of high-performance plastic skylight panels and assemblies using advanced polymers like PC and PEEK for railway applications.

Custom mould design and development for railroad skylight components, ensuring optimal part geometry and manufacturing efficiency.

Our CNC plastic machining services deliver railroad skylight components that withstand extreme weather conditions, UV exposure, and constant vibration. Using advanced polymers and state-of-the-art PLC-controlled machinery, we ensure every component meets stringent railway safety standards while maintaining optical clarity and structural integrity for reliable transit lighting systems.

Four decades of precision engineering excellence in plastic component manufacturing.

42 years of specialized experience in precision plastic polymer engineering and railway applications.

State-of-the-art PLC-controlled CNC machinery ensuring consistent quality and tight tolerances.

Comprehensive in-house testing capabilities with full documentation for railway industry compliance.

Complete in-house tool room capabilities for custom railroad skylight component development.

Experienced professionals driving innovation in plastic component manufacturing.

Chairman of Jairaj Group

As Chairman of Jairaj Group, Rajiv K Chawla has been instrumental in transforming the company from a single manufacturing unit established in 1985 into a nationwide network of advanced facilities. Under his leadership, Jairaj Group has expanded to six strategic locations across India, including specialized plants in Faridabad, Rudrapur, Aurangabad, Sanand, and Gurugram. His vision for precision engineering and quality excellence has earned the company recognition from Industry Outlook Magazine and inclusion in FORBES INDIA's DGEMS 2024 list. Chawla's commitment to innovation has guided the company's expansion into critical industries including railways, aerospace, and automotive sectors, establishing Jairaj Group as a trusted partner for complex plastic component manufacturing.

What types of plastics can be CNC machined for railroad skylights?

We specialize in machining high-performance polymers including polycarbonate (PC), PEEK, and other UV-resistant materials that meet railway industry standards for clarity, impact resistance, and weatherability.

What tolerances can you achieve with CNC plastic machining?

Our state-of-the-art PLC-controlled CNC machinery can achieve tight tolerances as precise as ±0.05mm, ensuring perfect fit and function for railroad skylight assemblies.

Do you provide testing and certification for railway applications?

Yes, we offer comprehensive in-house testing capabilities with full documentation to ensure compliance with railway industry safety standards and specifications.

Can you handle both prototyping and production volumes?

Absolutely. Our facilities are equipped for everything from rapid prototyping to high-volume production runs, with scalable manufacturing processes to meet your project requirements.

What is the typical lead time for CNC machined railroad skylight components?

Lead times vary based on complexity and quantity, but our efficient processes and multiple manufacturing facilities allow us to provide competitive delivery schedules typically ranging from 2-6 weeks.

Do you offer custom tooling development for unique skylight designs?

Yes, our in-house tool room capabilities allow us to develop custom tooling and fixtures specifically designed for your unique railroad skylight component requirements.

What quality control measures are in place during manufacturing?

We maintain ISO 9001:2015 certification and implement rigorous quality control throughout the manufacturing process, including dimensional inspection, material verification, and functional testing.

Can you work with existing skylight designs or provide engineering support?

Our Research, Development & Value Engineering Centers can both manufacture to existing specifications and provide design optimization services to improve manufacturability and performance.

Connect with our engineering team for detailed technical consultation and custom solutions.

Quality management system certification

Featured in FORBES INDIA 2024

Top manufacturer recognition by Industry Outlook

Get expert consultation and a detailed quote for your CNC plastic machining requirements.

For immediate assistance, feel free to give us a direct call at +91-9711-114-300 You can also send us a quick email at japl@jairajgroup.com

For immediate assistance, feel free to give us a direct call at +91-9711-114-300 You can also send us a quick email at japl@jairajgroup.com

Get the latest from the Fabrik newsroom